Plasma device and workpiece position detection method

A technology of plasma and equipment, applied in the field of plasma equipment and workpiece position detection, can solve the problems of reduced production efficiency, increased production cost, broken wafer 107, etc., to reduce the possibility of damage, reduce the possibility of bad chips or Fragmentation, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order for those skilled in the art to better understand the technical solution of the present invention, the plasma device and the workpiece position detection method provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

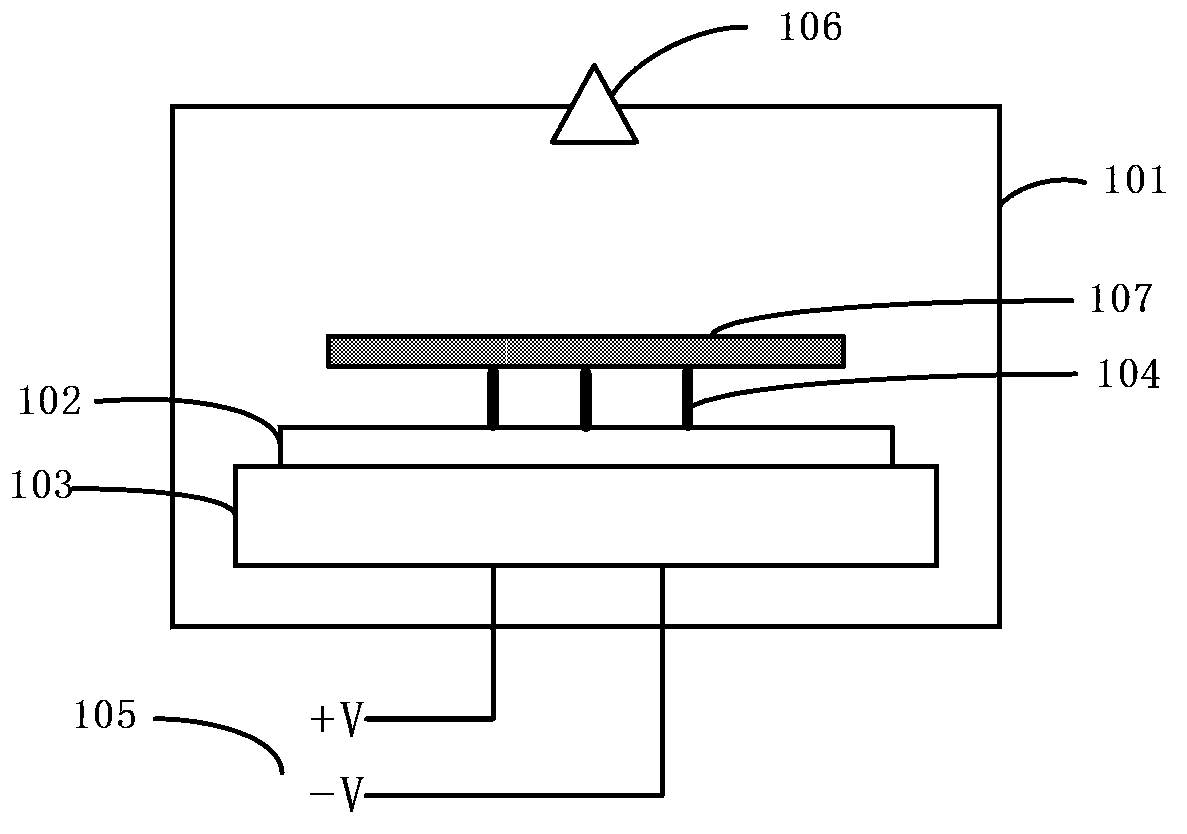

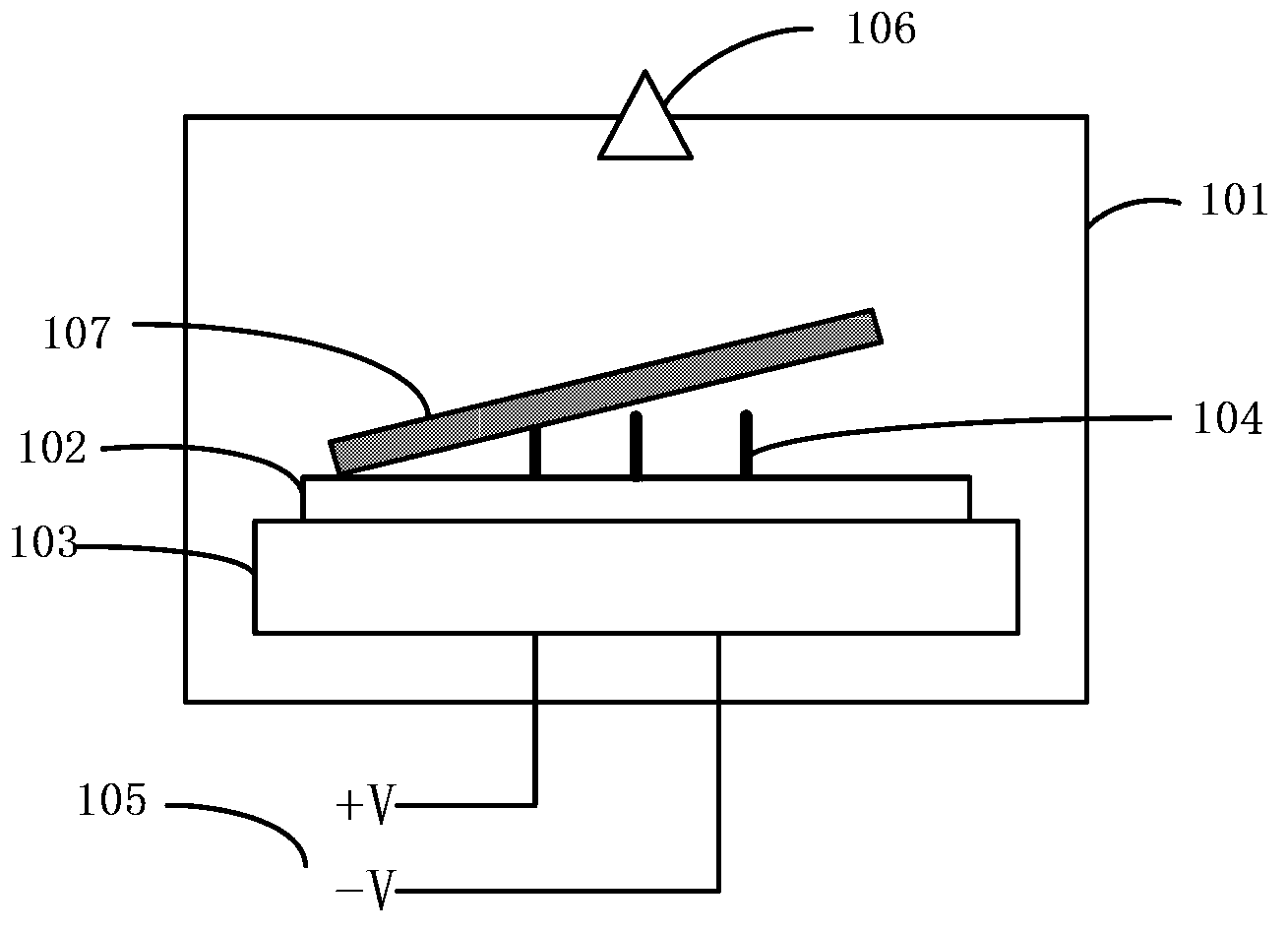

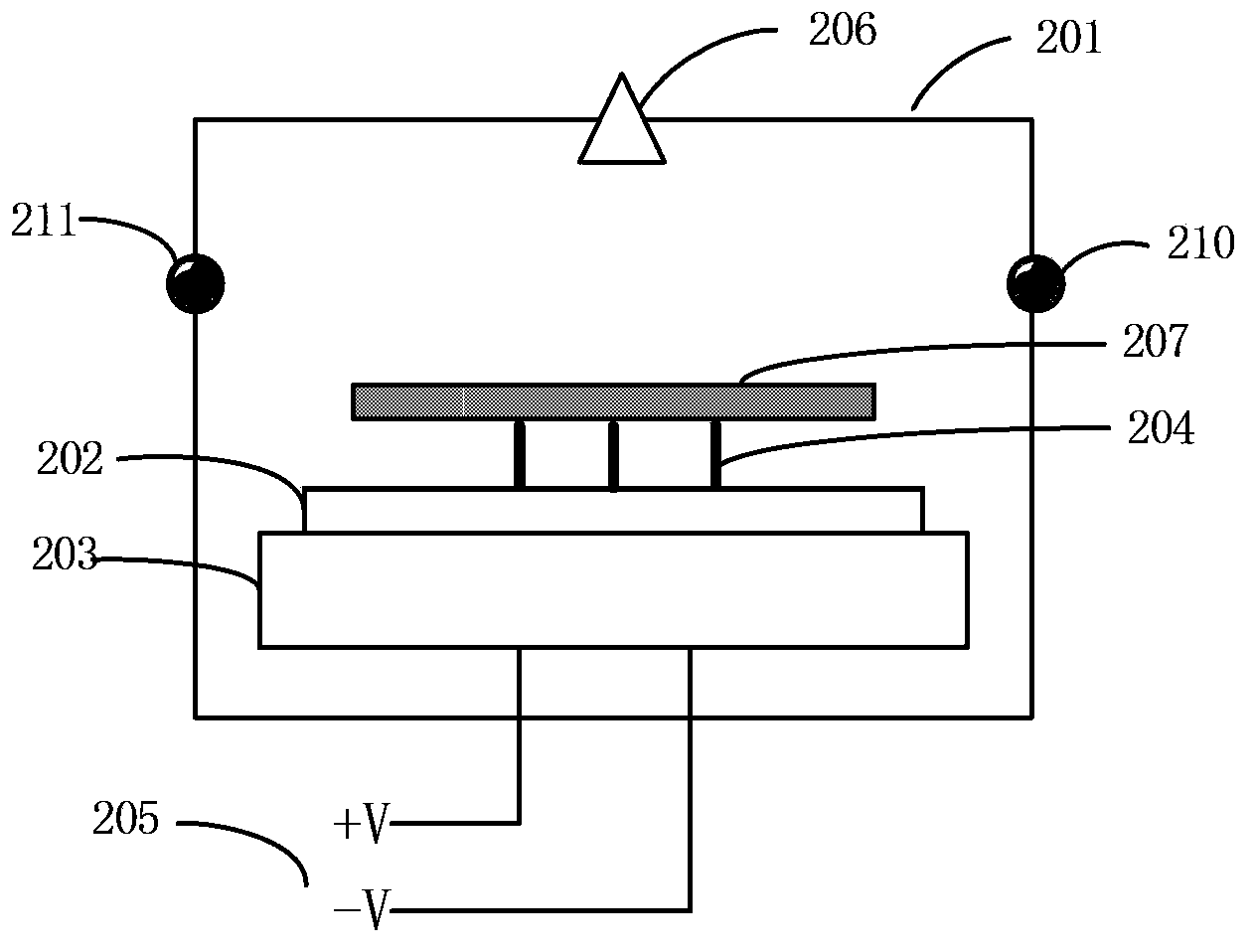

[0045] Embodiment 1 of the present invention provides a plasma device. see image 3 , which shows a schematic structural diagram of the plasma device provided by Embodiment 1 of the present invention. Such as image 3 As shown, the plasma equipment includes a reaction chamber 201, an electrostatic chuck 202 inside the reaction chamber 201, an electrostatic chuck base 203, a thimble 204, and an electrostatic power supply 205 outside the reaction chamber. The electrostatic chuck 202 is used to carry the workpiece 207 to be processed. The plasma device also includes a sensor for detecting the position of the workpiece. The sensor includes a sending module 210 and a receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com