A method for measuring the instantaneous amount of coal fed into the furnace by a double-inlet and double-outlet coal pulverizer

A technology of coal quantity into the furnace, double input and double output, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem that the instantaneous coal quantity cannot be directly measured, coal quantity is inconsistent, Affecting the concentration of wind powder and other issues to achieve the effect of improving safety and economy, practicality and simplicity, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

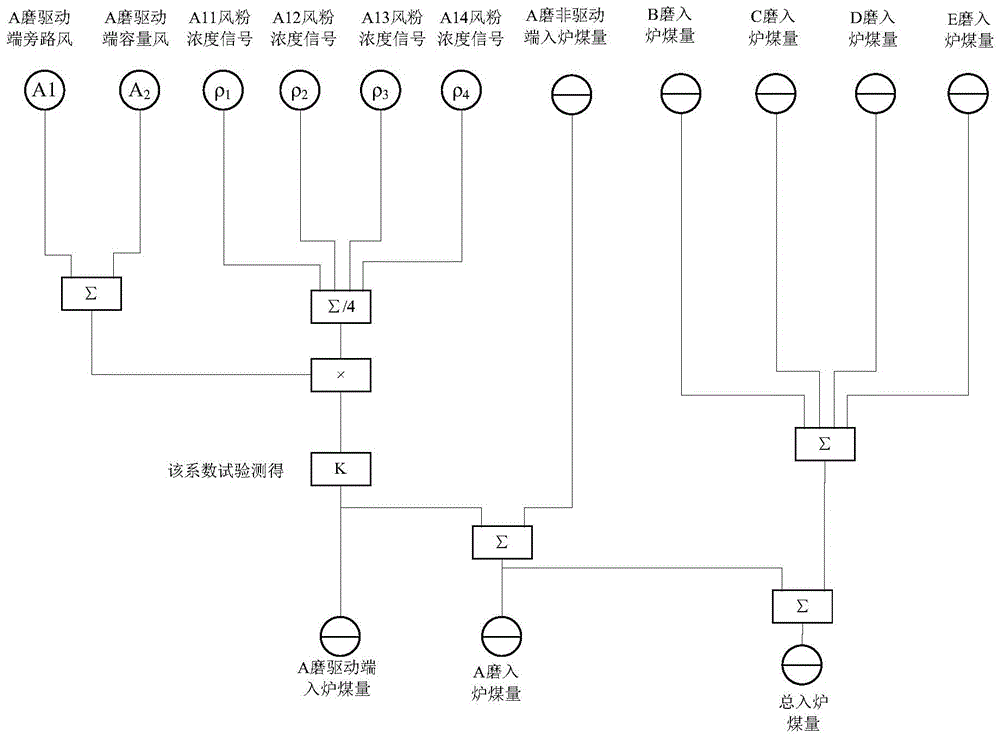

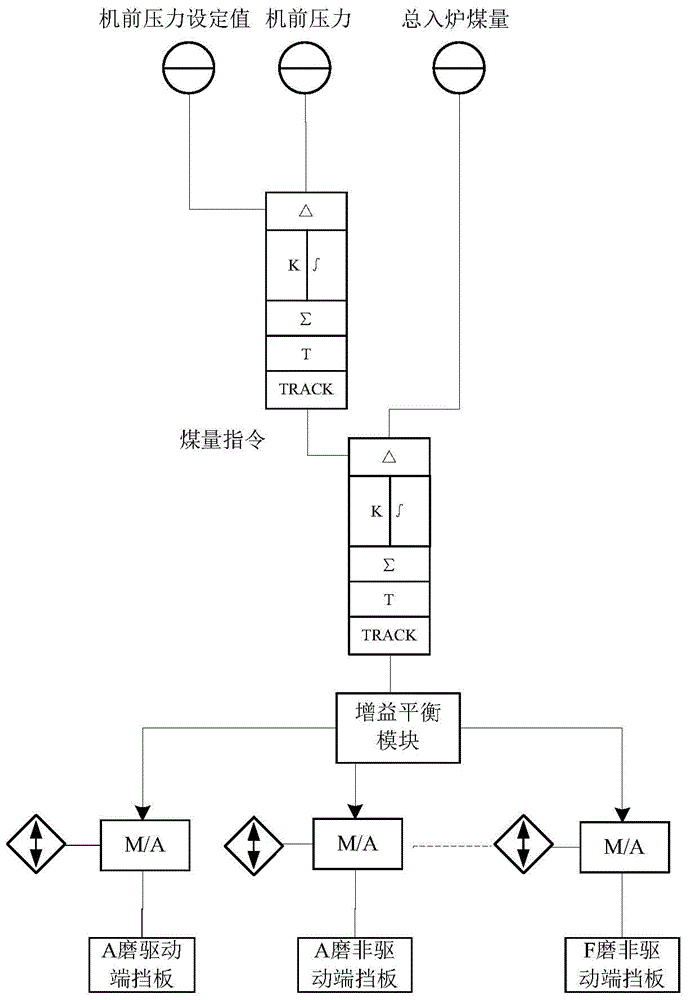

[0038] The following is an example of a 600MW subcritical coal-fired power generation unit. The unit is equipped with 5 double-inlet and double-outlet coal mills, namely A, B, C, D, and E coal mills. The wind power of each coal mill The powder outlet is divided into a driving end and a non-driving end. The primary air at each end enters the corresponding burner through four primary air pipes for combustion. Taking the driving end of A coal mill as an example, the primary air entering the furnace includes capacity air and bypass wind, the flow signal is Q r , Q p , and the corresponding temperature signals are t r , t p , the measuring point of the air powder concentration is arranged on each primary air duct, denoted as ρ a1 , ρ a2 , ρ a3 , ρ a4 , The control of the main steam pressure of the boiler is mainly adjusted by the amount of coal fed into the furnace.

[0039] Step 1: Primary Air Volume Measurement and Calculation

[0040] Taking the driving end of coal mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com