A punching die stroke limit device

A stroke limit and die technology, which is applied in the field of punching die stroke limit devices, can solve problems such as damage to press equipment, influence of punching precision, equipment die precision, and stroke limit column closure, so as to avoid direct closure. and damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

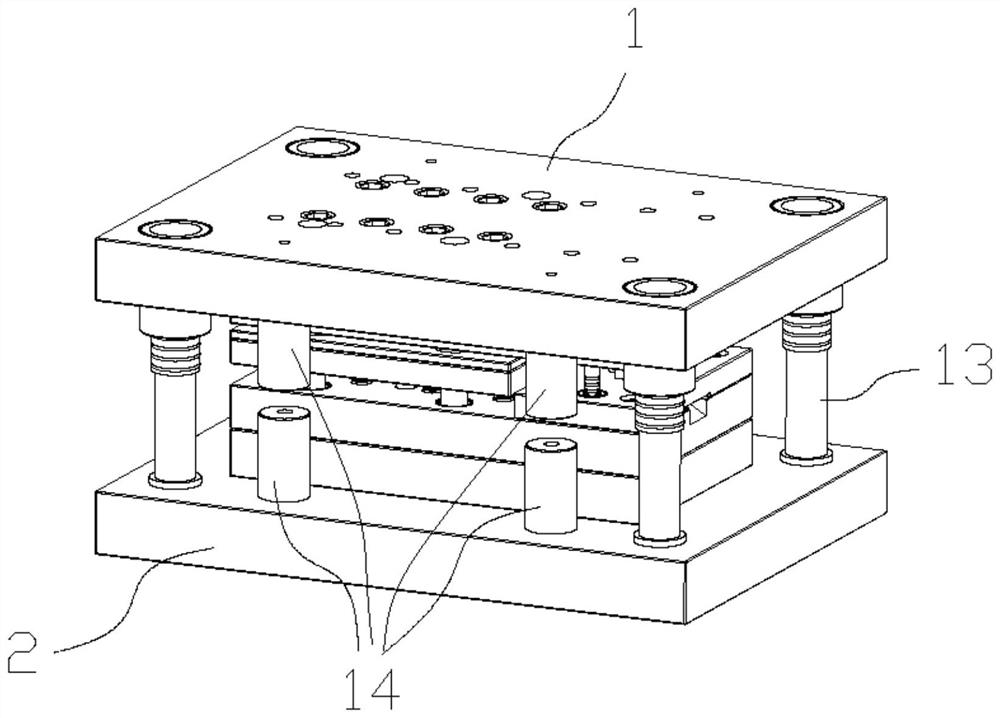

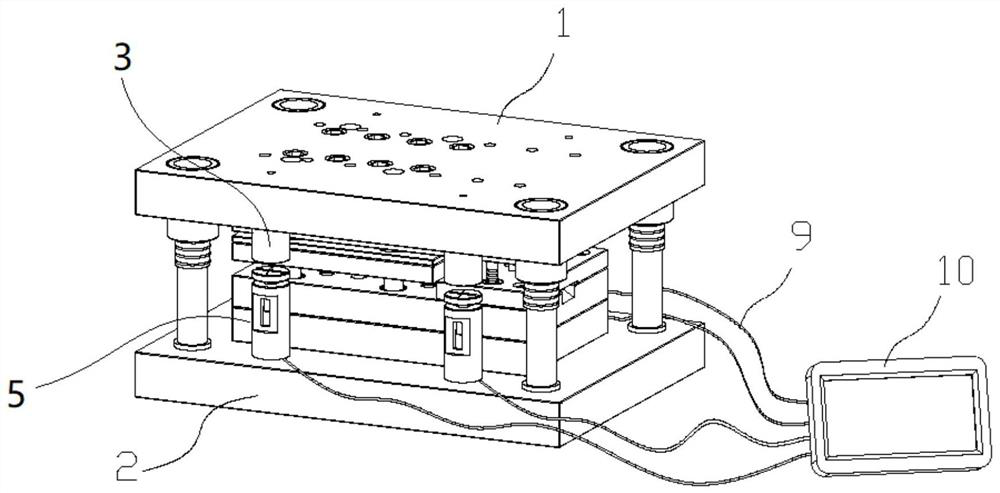

[0027] like figure 2 , 3 , 4 shown:

[0028] A stroke limiting device for a blanking die, comprising a stroke limiting device body, the stroke limiting device body comprising an upper stroke limiting column 3 whose upper end is fixedly connected to an upper die base 1 , and a lower end that is fixedly connected to the lower die base 2 . The lower travel limit column 5, the limit column travel detection mechanism, and the limit column travel protection mechanism, the upper travel limit column 3 and the lower travel limit column 5 are arranged coaxially in the longitudinal direction and used in cooperation with each other, so The lower travel limit post 5 is respectively connected with the limit post travel detection mechanism and the limit post travel protection mechanism.

[0029] This embodiment provides the most basic structure of the present invention. The closed state of the upper die base and the lower die base and whether they are parallel can be detected by the limit...

Embodiment 2

[0031] This embodiment is an improvement made on the basis of Embodiment 1, specifically:

[0032] like figure 2 , 3 , 4 shown:

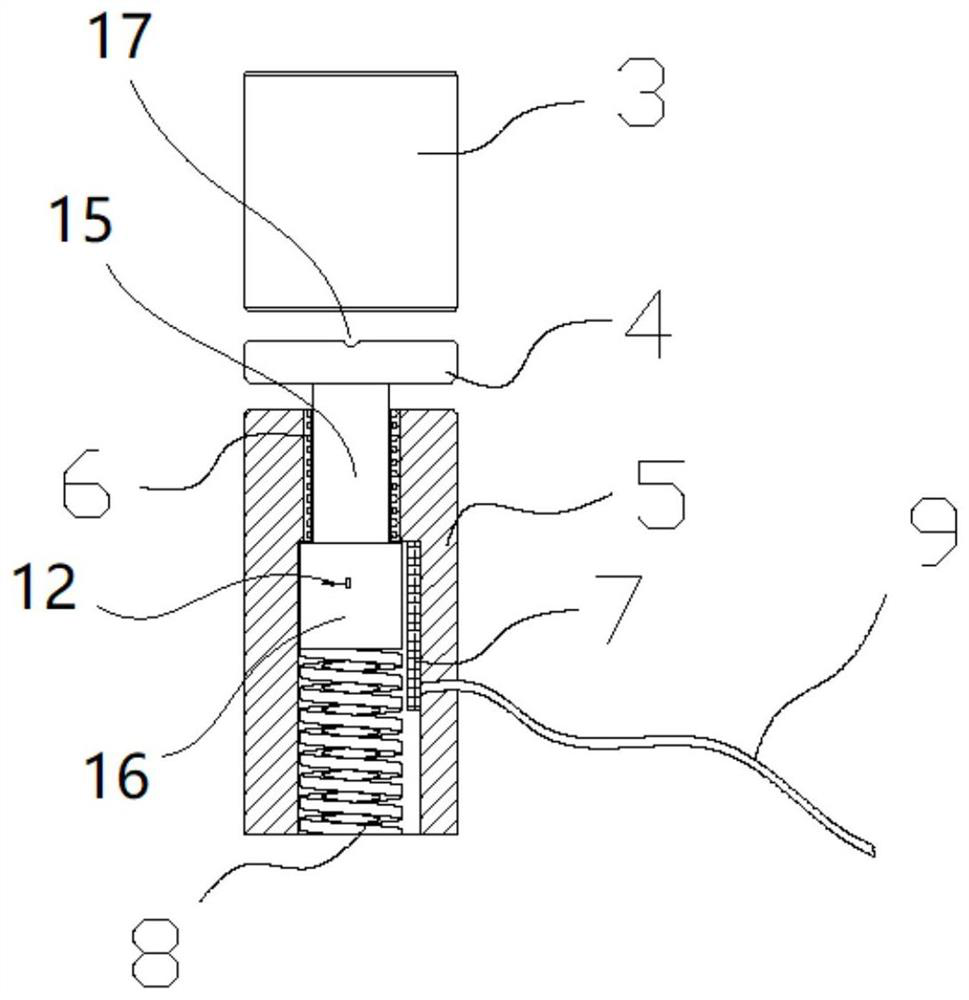

[0033] The top of the lower travel limit post 5 is provided with an installation groove extending along the axis of the downward travel limit post 5, and the limit post stroke detection mechanism includes a steel ball guide coaxially arranged in the upper part of the installation groove. Sleeve 6, a sliding rod 15 slidably connected to the steel ball guide sleeve 6, a detection block 4 fixedly connected to the top of the sliding rod 15 and located above the lower travel limit column 3, a limit base 16 fixedly connected to the bottom end of the sliding rod, set at the limit The spring 8 under the base, the observation port 18 opened on the wall of the installation groove where the side wall of the limit base is located, the scale 11 longitudinally arranged on one side of the outer surface of the observation port 18, and the horizontal The pointer...

Embodiment 3

[0040] This embodiment is an improvement made on the basis of Embodiment 2, specifically:

[0041] like figure 2 , 3 , 4, the limit post stroke protection mechanism includes: a grating ruler 7, a signal line 9, and a display control unit 10 installed on the groove wall of the installation groove below the steel ball guide sleeve 6, the grating ruler 7 is used to detect the distance that the limit base moves downward, the grating ruler 7 is connected with the display control unit 10 through the signal line 9 passing through the wall of the installation groove, and the display control unit 10 will detect the signal of the grating ruler 7. It is displayed on the display screen, and the press is controlled by a preset control program, and the display control unit is electrically connected to the emergency braking control circuit of the press through a wire;

[0042] When the grating ruler 7 detects the position when the pointer mark of the limit base points to the bottom dead c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com