Spray-rolling type loose fiber washing process

A loose fiber, shower-rolling technology, applied in the direction of liquid/gas/vapor removal with squeeze rollers, spray/jet textile material processing, textile material carrier processing, etc., can solve the problem of high washing cost, high cleaning cost and water consumption. It can ensure continuity and stability, stable transmission process and less water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

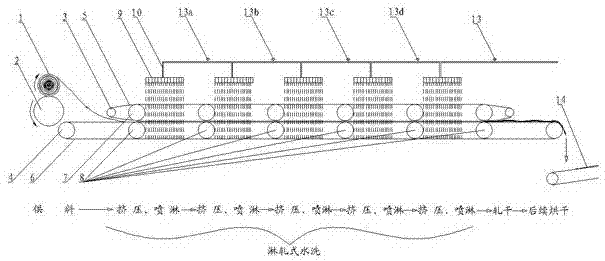

[0022] In this example, combined with figure 1 , the rolling-type loose fiber washing process, including three steps of feeding, rolling-type washing and subsequent treatment, the loose-fiber roll 1 after cold-batch dyeing and color fixing passes through the cotton-feeding roller 2 at the rolling-type washing device, and is guided by the belt The transmission method is extruded and sprayed alternately. After multiple groups of rolling water washing are carried out, the water is dried and output, and the feeding is carried out synchronously with the belt conveyor; the rolling washing device mainly includes the transmission part and the spraying part. Cotton feeding roller 2 is located in front of the conveying part, and the spraying part is located above the conveying part, specifically:

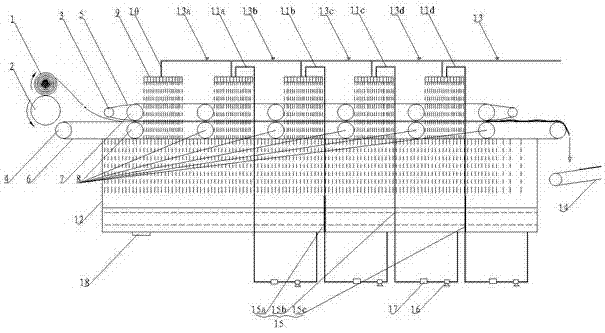

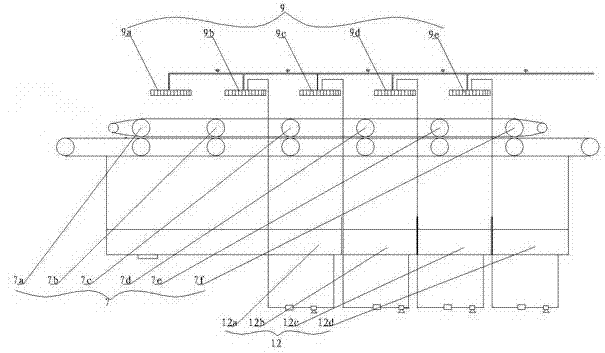

[0023] combine figure 2 , the transmission part is made of upper guide belt 5, lower guide belt 6, upper roller 7, lower roller 8, a pair of upper driving rollers 3 and a pair of lower driv...

Embodiment 2

[0028] In this embodiment, a liquid collecting tank 12, a return pipe, a water pump 16 and a heat exchanger 17 are arranged below the conveying part. 17 are all installed on the return pipe, the water pump 16 draws the liquid in the liquid collection tank 12 into the spraying part for reuse, and the heat exchanger adjusts the reused liquid to a suitable temperature for use; figure 2 , three partitions 15 are arranged in the sump 12, which are respectively partition one 15a, partition two 15b and partition three 15c. The purpose is to divide the sump 12 into several liquid accumulation areas. Considering the effect comprehensively, the separator one 15a is arranged at the liquid sump corresponding to the bottom of the upper roller three 7c and the upper roller four 7d, and the second separator 15b is arranged at the corresponding collector below the upper roller four 7d and the upper roller five 7e. At the liquid tank, the partition three 15c is arranged at the sump 12 corresp...

Embodiment 3

[0030] Embodiment 3: comparative example

[0031] Conventional cleaning of loose fibers requires multi-channel washing, soaping and hot water washing. The loose fibers are placed in the washing tank for soaking and cleaning. During the cleaning process, an additional heat source is required for heating. At the same time, a certain amount of soaping agent etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com