All-in-one machine capable of achieving fast switching between bartacking function and buttonholing function

A fast-switching, all-in-one machine technology, applied in the field of tacking machines, can solve the problems of large demand for labor and production equipment, increasing the number and complexity of processes, and lack of eye opening, etc., to improve the scope of application, fast speed, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

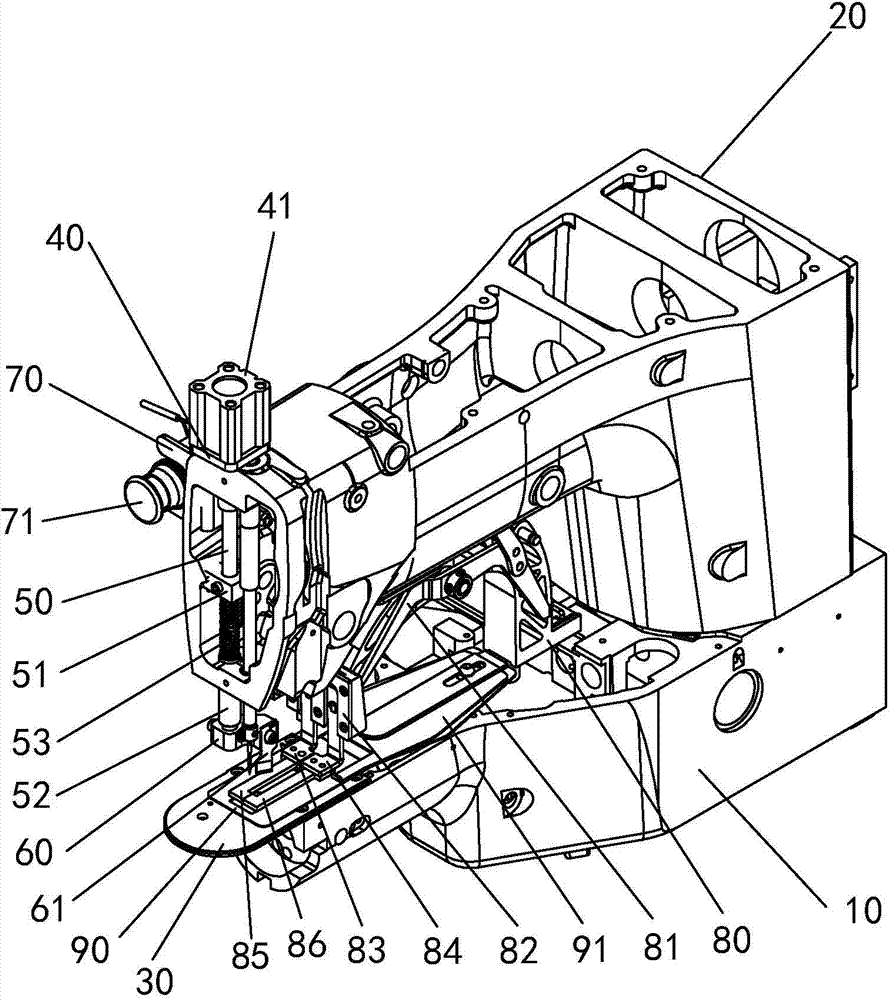

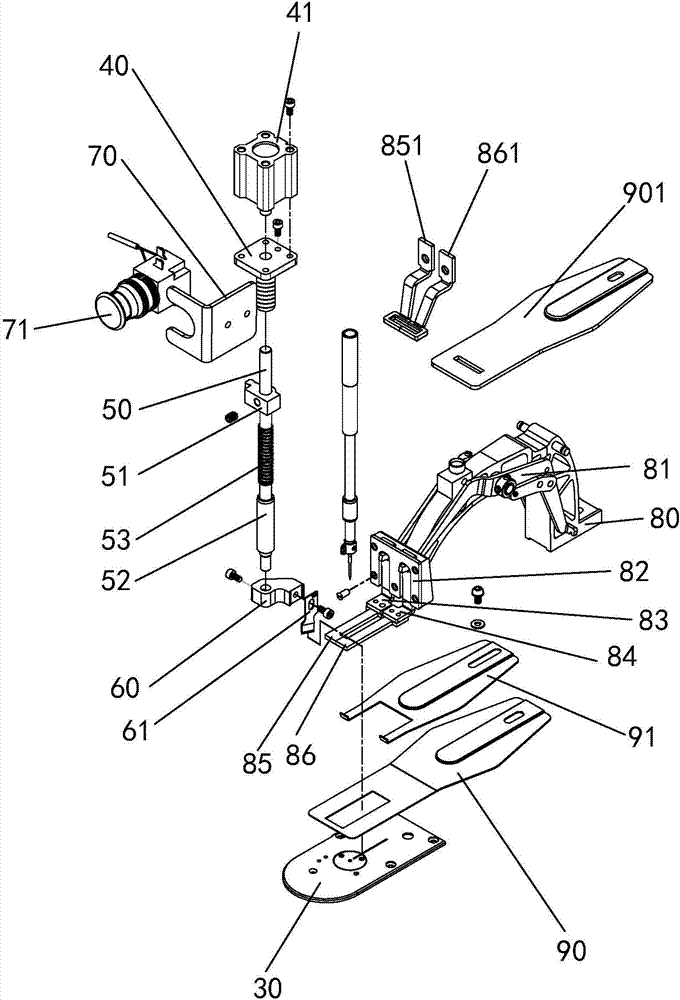

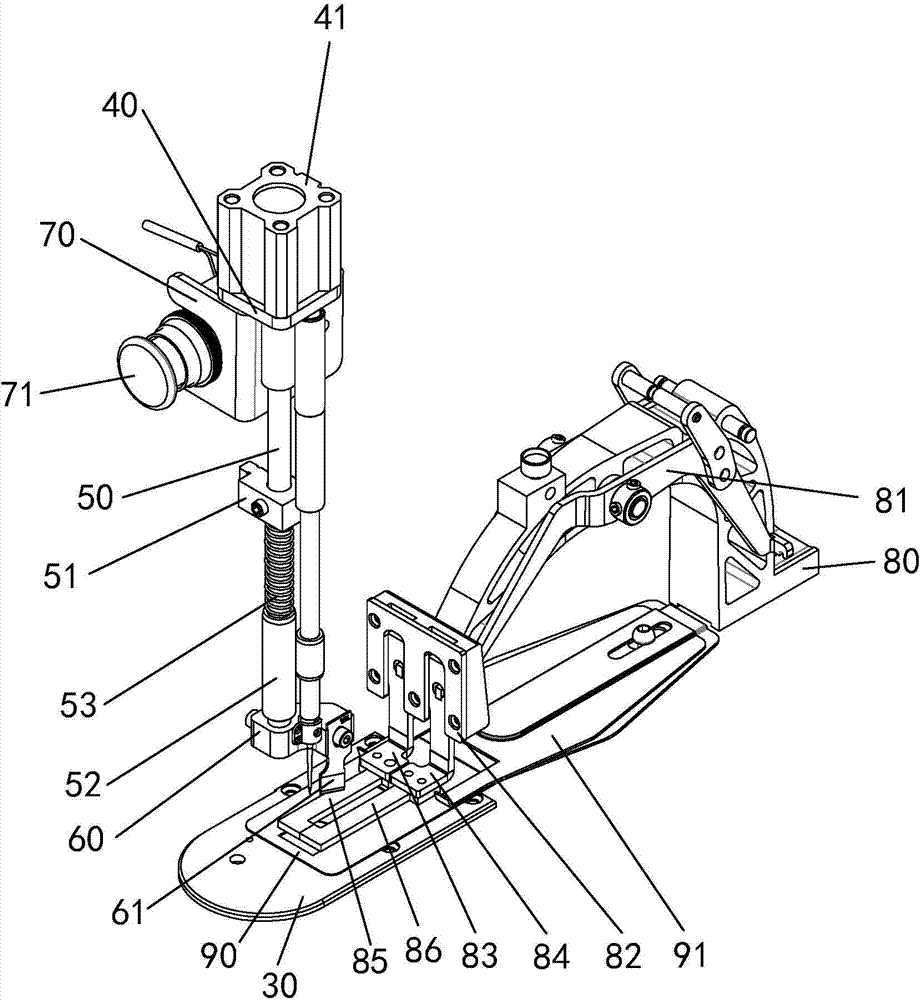

[0021] like Figure 1 to Figure 3 As shown, it is an all-in-one machine for fast switching between tacking and keyhole functions disclosed in the present invention, which includes a machine base 10 and a machine base 20 installed on the machine base 10. The machine base 10 is provided with a needle plate 30, so The upper side of the machine base 20 is provided with a tacking mechanism, and one side of the machine base 20 which is located at the tacking structure is provided with an automatic keyhole cutting device controlled by a controller and a fast switch on the machine table 10. device, the quick switching device is located on the lower side of the automatic keyhole cutting device. Since the tack mechanism is a basic function of traditional equipment, redundant statements will not be made in this embodiment.

[0022] In the above, the automatic keyhole cutting device includes an automatic knife cutter mechanism and a manual knife cutter mechanism, and the manual knife cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com