Different warp fabric and its weaving process

A fabric and technology technology, applied in the field of different warp fabrics and its weaving technology, can solve the problems of broken warp of the cloth surface and difficult to control the tension, and achieve the effects of low weaving difficulty, quality assurance and avoiding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

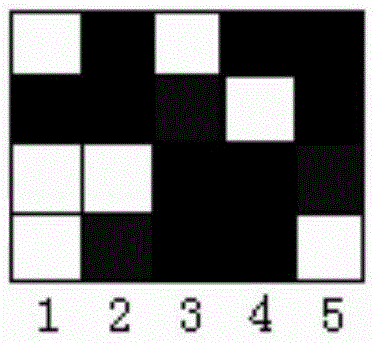

[0021] Such as figure 1 As shown, the fabric is designed with a 72:1 ratio of regular warp yarns to special warp yarns, and a 3 / 1 broken twill weave.

[0022] Wearing method one is: 5, 2, 3, 4 (65 roots) + 1 (1 time) + 2, 3, 4, 5 (18 times)

[0023] Note: The regular warp is worn on page 2.3.4.5, and the special warp is worn on page 1.

[0024] (The numbers represent the number of pages where the warp thread passes on the heald frame).

Embodiment 2

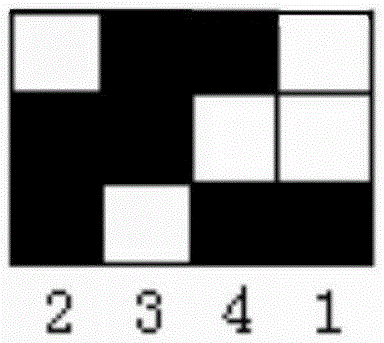

[0026] Such as figure 2 As shown, the fabric design is that the ratio of regular warp yarns to special warp yarns is 60:1, and the fabric weave is 2 / 1 right twill.

[0027] How to wear: 4, 2, 3 (37 roots) + 1 (1 time) + 2, 3, 4 (20 times)

[0028] Note: The regular warp is worn on pages 2, 3 and 4, and the special warp is worn on page 1.

[0029] (The numbers represent the number of pages where the warp thread passes on the heald frame).

[0030] The specific implementation process steps of the present invention are: winding process → warping process → sizing process → reed process → weaving process → finishing process:

[0031] (1) Winding process: use an automatic winder to wind the bobbin into a bobbin with a large capacity and a certain density, and remove impurities to remove defects and impurities on the yarn;

[0032] (2) Warping process: the arrangement of special yarns should be specially designed (that is, the special warps are arranged on the warping machine according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com