Method for preparing aluminum-titanium intermediate alloy by recycling titanium scrap or titanium leftover material

A technology for master alloys and scraps is applied in the field of preparing aluminum-titanium master alloys, which can solve the problems of low utilization rate of titanium scraps or titanium scraps, and achieve the effects of saving cost and energy consumption, simple production process and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

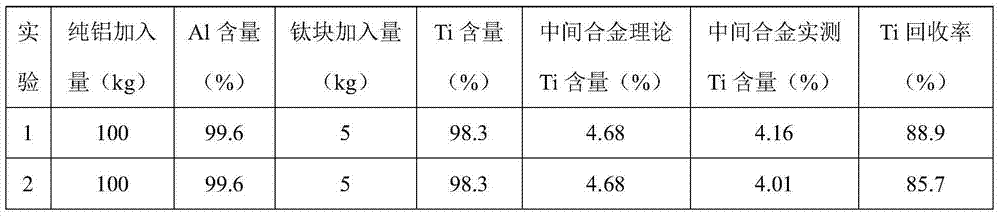

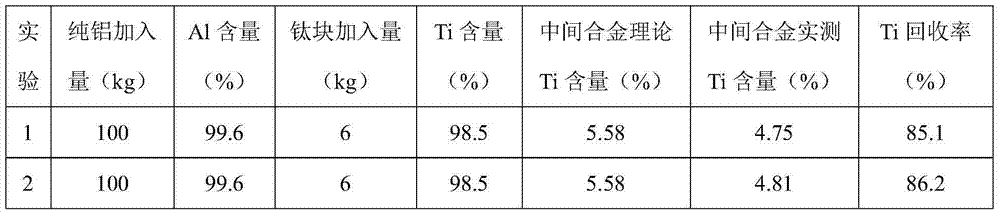

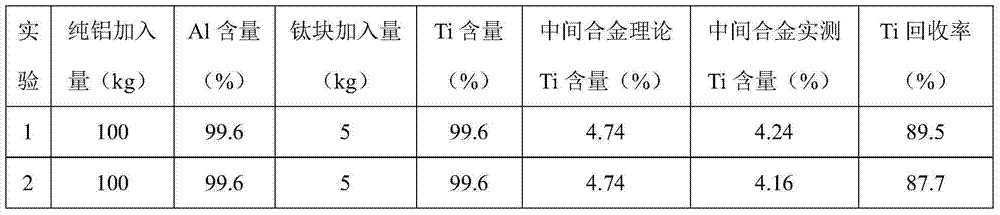

[0012] Specific implementation mode 1: In this implementation mode, the method for preparing an aluminum-titanium master alloy by recycling titanium shavings or titanium scraps is implemented according to the following steps:

[0013] 1. Pulverize the titanium shavings or titanium scraps produced in the production and processing on the crusher, and dry the titanium blocks obtained after degreasing, and then pack the dried titanium blocks into bags with aluminum foil to obtain bagged titanium blocks;

[0014] 2. After melting pure aluminum in the melting furnace, evenly sprinkle the preheated covering agent on the surface to obtain molten aluminum;

[0015] 3. Raise the temperature of the molten aluminum to 850-880°C, add 1 / 2 of the required bagged titanium block according to the mass ratio of aluminum to titanium in the aluminum-titanium master alloy to be prepared by using the bell jar press-in method, and stir for 15-20 minutes Keep warm for 4 to 5 minutes, then add the rema...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the size of the titanium block obtained by crushing in step 1 is less than 5 mm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the aluminum foil used in step 1 is a medium-thick foil of 0.025-0.05 mm or a thick foil of 0.05-0.2 mm. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com