A combined hydrocracking method for processing inferior raw materials

A technology for hydrocracking and raw materials, which is applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of consumption of lean amine liquid, lower total income, complicated operation, etc., so as to reduce the consumption of amine liquid and reduce Overall investment, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

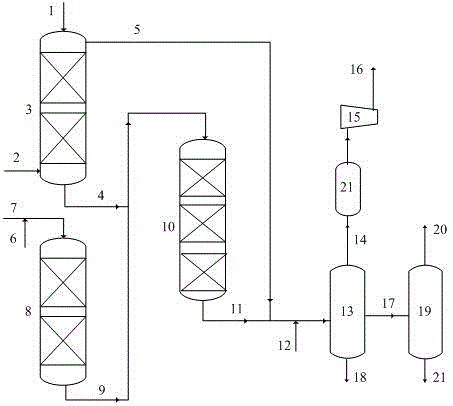

[0035] use figure 1 In the process flow shown, the pretreatment reactor A and pretreatment reactor B of the hydrocracking unit for processing different feedstock oils are organically combined. Wherein the pretreatment reactor B adopts the countercurrent hydrogenation process. The properties of the catalysts used in the examples are listed in Table 1. The catalyst is a commercial catalyst developed and produced by Fushun Petrochemical Research Institute.

[0036] The operating conditions and test results are listed in Table 4.

[0037] Table 1 The main physicochemical properties of the catalyst.

[0038] project FF-36 FC-14 Appearance shape Clover Strips Cylindrical bar Particle diameter, mm 1.1~1.3 1.5~1.7 Strip length, mm 3~8 3~8 Crushing strength, N / cm ≥180 >185 Chemical composition, wt% Mo-Ni W-Ni NiO 3.7~4.2 5.2~6.0 MoO 3 23.0~26.0 — WO 3 — 20.5~23.5

[0039] Table 2 Raw oil properties tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com