Porous concrete prepared from waste concrete aggregate and preparation method thereof

A waste concrete and porous concrete technology, applied in the field of concrete, can solve the problems of high water absorption, affecting engineering applications, and low strength of porous concrete, and achieve the effects of good toughness, high tensile and flexural ultimate strength

Inactive Publication Date: 2014-05-07

XUZHOU UNIV OF TECH

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional treatment methods are landfill or stacking, which not only consumes a lot of construction costs such as arable land and garbage removal, but also puts a lot of pressure on environmental governance

[0004] When waste concrete is used as the aggregate of porous concrete, there are often problems of low aggregate strength and high water absorption. Direct use will lead to problems such as low strength and large shrinkage of porous concrete, which will affect the application of the project.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

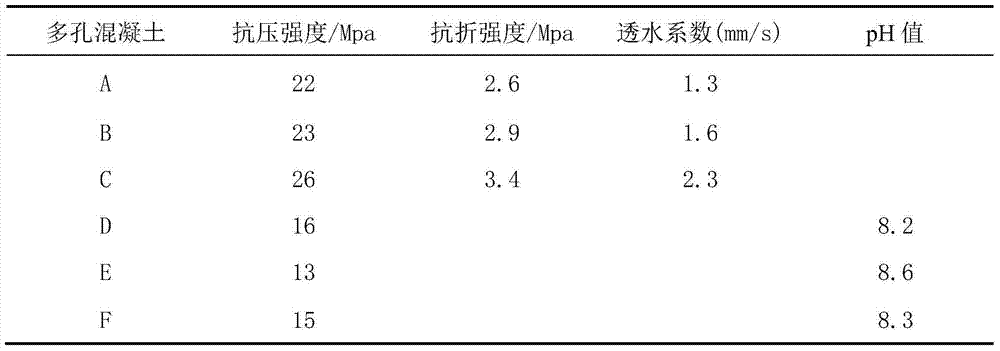

[0024] Cement 260kg, sand 180kg, gradation 5-20 recycled aggregate 1300kg, polypropylene fiber 1.2kg, water 92kg, admixture 3.5kg. Label A.

Embodiment 2

[0026] Cement 270kg, sand 175kg, gradation 5-20 recycled aggregate 1350kg, polypropylene fiber 1.5kg, water 95kg, admixture 3.8kg. Label B.

Embodiment 3

[0028] Cement 280kg, sand 190kg, gradation 5-20 recycled aggregate 1400kg, polypropylene fiber 1.8kg, water 99kg, admixture 4.0kg. Label C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

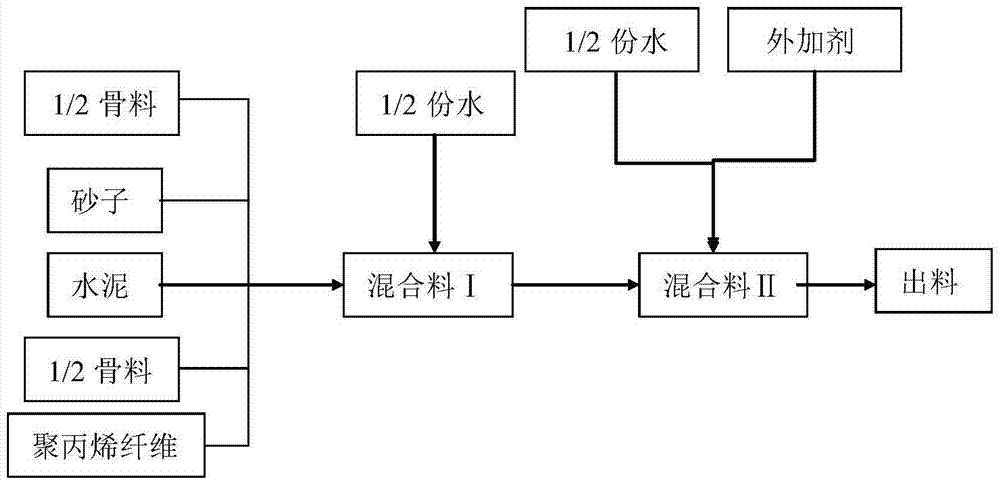

The invention discloses porous concrete prepared from waste concrete aggregate and a preparation method thereof. The porous concrete comprises 1-4 parts of polypropylene fiber, 250-300 parts of cement, 1200-1500 parts of recycled aggregate, 130-160 parts of sand, 90-110 parts of water, and 3-6 parts of admixture, wherein the admixture comprises 20-25 parts of a polycarboxylate superplasticizer, 10-15 parts of ferric sulfate, 10-15 parts of limestone powder and 50-60 parts of active silica solid particles. The preparation method comprises the following steps: firstly preparing the recycled aggregate of waste concrete, then mixing and stirring the polypropylene fiber, the cement, the recycled aggregate, the water and the admixture according to a mixture ratio, and uniformly stirring the mixture within corresponding time, thus obtaining the porous concrete. The waste concrete can be recycled and serves as the aggregate for preparing the porous concrete; meanwhile, the strength of the prepared porous concrete is improved, and the pH value is reduced, so that the normal use of the porous concrete in architectural engineering is ensured.

Description

technical field [0001] The invention relates to porous concrete prepared from waste concrete aggregates and a method thereof, belonging to the technical field of concrete. Background technique [0002] Porous concrete is a kind of concrete with a special pore structure, which is made of specific graded aggregates, cement, water, admixtures, etc. through special processes. The excellent air permeability and water permeability of porous concrete make it widely used on both sides of urban roads, river slope protection, roofs and parking lots, etc., to improve the heat and humidity exchange capacity, reduce the surface temperature of concrete materials, and increase the green space of the city. The positive role of maintaining the urban climate and ecological balance. [0003] With the development of my country's economy and the continuous deepening of urbanization, the establishment of new buildings and the demolition of old buildings have produced a large amount of constructi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/00C04B16/06C04B18/16

CPCY02W30/91

Inventor 朱炯薛冬杰韩维纲张连英杨捷谢晓晖

Owner XUZHOU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com