Method and apparatus for preparing large particle size spherical tricobalt tetreoxide

A technology of cobalt tetroxide and large particle size, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problem of inability to prepare cobalt tetroxide particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

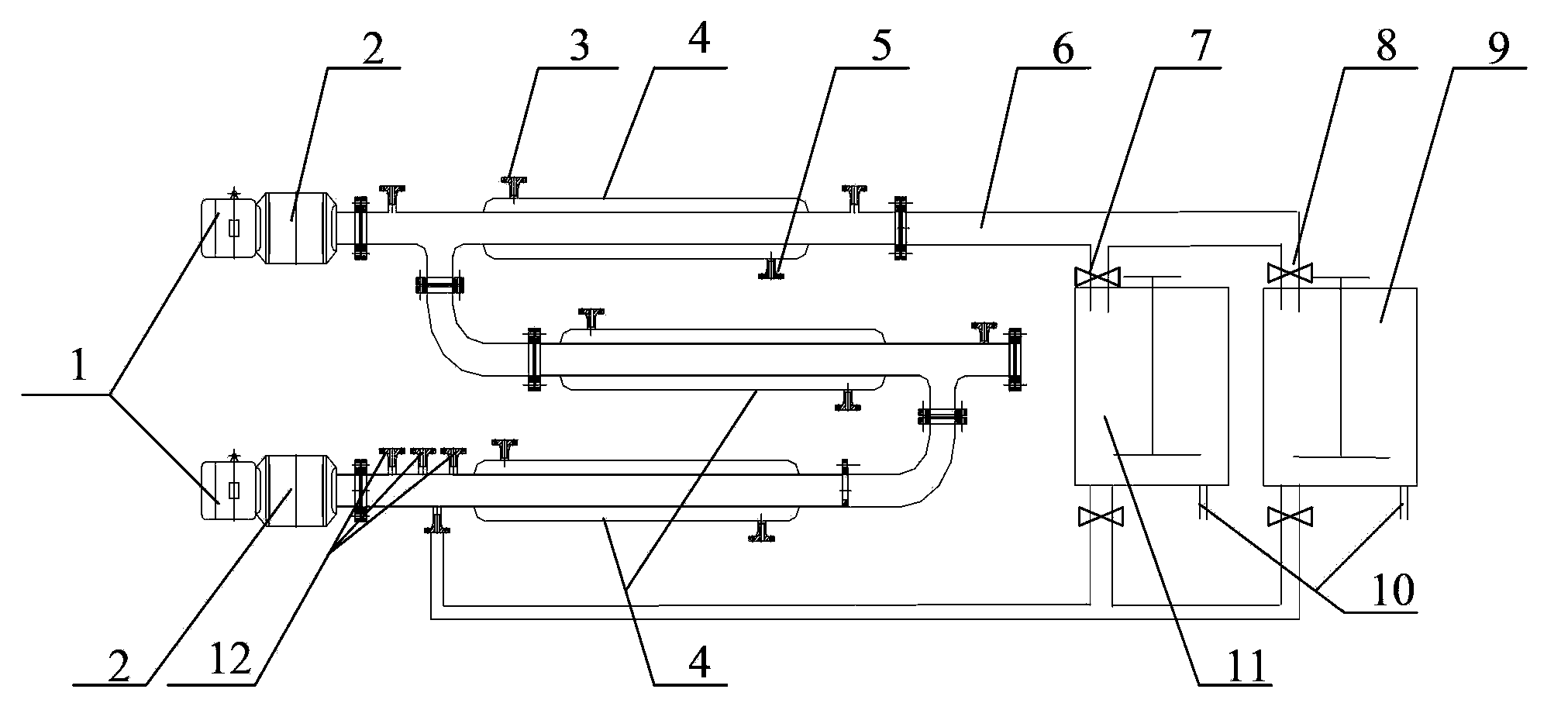

preparation example Construction

[0032] The main purpose of the method for preparing large-diameter spherical cobalt tetroxide provided by the embodiment of the present invention is to solve the problem that cobalt trioxide particles with a diameter of 14 microns or more cannot be grown in the current reactor. The method includes:

[0033] Step S1: Prepare mixed solution:

[0034] First, configure the selected cobalt salt into a 60-120g / L cobalt salt solution, and then add a complexing agent to the cobalt salt solution to prepare a mixed solution for use;

[0035] Step S2: Configure the hydroxide solution:

[0036] Configure the selected hydroxide to be a hydroxide solution with a concentration of 8-11mol / L for use;

[0037] Step S3: Feeding:

[0038] The feeding method of the present invention adopts the method of feeding in parallel. Specifically, the above-mentioned configured mixed solution and hydroxide solution and an appropriate amount of air are simultaneously and concurrently flowed into the reacti...

Embodiment 1

[0047] First prepare 60g / L of cobalt chloride solution, add an appropriate amount of glycine to the feed liquid, configure it as a mixed solution, configure sodium hydroxide into an 8mol / L sodium hydroxide solution, mix the mixed solution, sodium hydroxide solution and an appropriate amount of The air flows into the reactor in parallel, and the total flow rate is controlled to be 100L / h, the pH is 10.5, the reaction temperature is 65°C, the stirring speed is 180rpm, and the bulk density of tricobalt tetroxide at the outlet of the reactor is 1.42g / cm 3 , D50=6.77 microns, the three cobalt tetroxide solution at the outlet of the reactor is re-introduced into the reactor with the mixed solution, sodium hydroxide solution and an appropriate amount of air to react, and after a period of time, the particle size of the outlet of the reactor is tested again to be D50 =14.05 microns.

Embodiment 2

[0049] Prepare the cobalt chloride solution of 120g / L, add an appropriate amount of disodium ethylenediaminetetraacetate in the feed liquid, configure it as a mixed solution, configure potassium hydroxide into a potassium hydroxide solution of 11mol / L, mix the solution, hydrogen Potassium oxide solution and an appropriate amount of air flowed into the reactor in parallel, and the total flow rate was controlled to 800L / h, the pH was 8, the reaction temperature was 80°C, and the stirring speed was 100rpm. Sampling and testing of loose cobalt tetroxide at the outlet of the reactor The density is 1.45g / cm 3 , D50=6.83 microns, the three cobalt tetroxide solution at the outlet of the reactor is re-introduced into the reactor with the mixed solution, potassium hydroxide solution and an appropriate amount of air to react, and after a period of time, the particle size of the outlet of the reactor is tested again to be D50 =14.16 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com