Preparation method of seaweed-based activated carbon for supercapacitor

A supercapacitor and activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of materials that cannot meet performance requirements, lack of artificial regulation of pore structure, etc., and achieve good energy storage and release capabilities, easy Operation, effect of large activation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Present embodiment relates to a kind of preparation method of activated carbon for supercapacitor based on seaweed, described method is as figure 2 shown, including the following steps:

[0034] Step 1, immerse 30g macroalgae into 0.001mol / L Ni(N0 3 ) 2 solution, let stand for 1 hour. Dried the impregnated macroalgae, calcined at 400°C for 1 hour under vacuum, added 1L hydrochloric acid (3mol / L), stirred for 2 hours, filtered, and dried to obtain carbonized macroalgae powder;

[0035] Step 2: Activate 3 g of carbonized macroalgae powder with water vapor at 750° C. for 1 hour to obtain an activated product;

[0036] Step 3: add the activated product obtained in the above step 2 into 1L of hydrochloric acid (1mol / L), stir for 2 hours, filter, and dry at 100°C to obtain activated carbon.

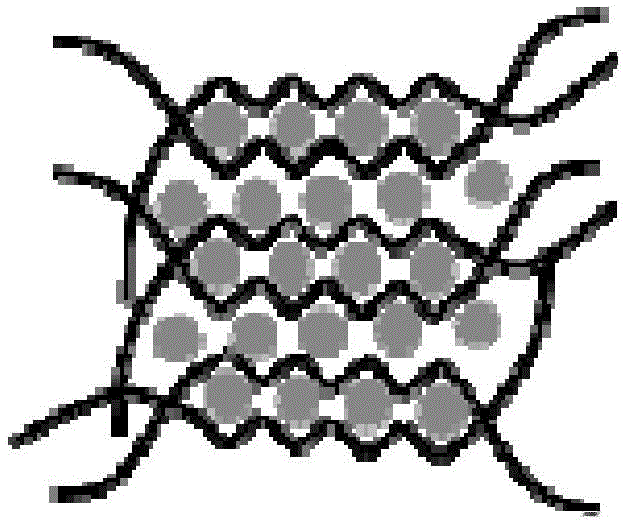

[0037] Implementation effect: see figure 1 , 2, 3, the impregnated Ni 2+ Afterwards, the algae formed as figure 1 The "egg-box" structure shown, behaves as image 3 The peak pos...

Embodiment 2

[0039] This embodiment relates to a preparation method of activated seaweed carbon for supercapacitors based on seaweed, the method is as follows figure 2 shown, including the following steps:

[0040] Step one, will grow in Ca-rich 2+ The seawater seaweed was directly calcined at 600°C for 2 hours under vacuum, added to 1L of hydrochloric acid (5mol / L), stirred for 2 hours, filtered, and dried to obtain the carbonized powder of the seaweed;

[0041] Step 2, adding 3g of undaria pinnatae carbonized powder into 20ml of KOH (4mol / L), heating at 100°C until evaporated to dryness;

[0042] Step 3, using water vapor to activate the mixture obtained in the above step 2 at 900° C. for 2 hours to obtain an activated product;

[0043] Step 4: Add the activated product obtained in Step 3 into 1L of hydrochloric acid (1mol / L), stir for 2 hours, filter, and dry at 100°C to obtain activated carbon.

[0044] Implementation effect: see Figure 4 , 6 As shown, the obtained activated car...

Embodiment 3

[0046] This embodiment relates to a preparation method of activated seaweed carbon for supercapacitors based on seaweed, the method is as follows figure 2 shown, including the following steps:

[0047] Step 1: Calcining 30 g of kelp at 900° C. for 3 hours under vacuum, adding 1 L of hydrochloric acid (2 mol / L), stirring for 2 hours, filtering, and drying to obtain carbonized kelp powder;

[0048] Step 2, add 3g of kelp carbonized powder into 20ml of KOH (6mol / L), heat at 100°C until evaporated to dryness;

[0049] Step 3, activating the product obtained in the above step 2 at 800°C for 1 hour;

[0050] Step 4: Add the activated product obtained in Step 3 into 1L of hydrochloric acid (1mol / L), stir for 2 hours, filter, and dry at 100°C to obtain activated carbon.

[0051] Implementation effect: see Figure 5 As shown, take 0.1g of activated seaweed carbon, add test materials, conductive carbon black, and binder according to the ratio of 1:1:8, roll it into a film, punch it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com