Residual oil hydrogenation catalyst, as well as preparation method and application thereof

A residue hydrogenation and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost, high price, low activity of spent catalysts, etc. , low price, and the effect of improving hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

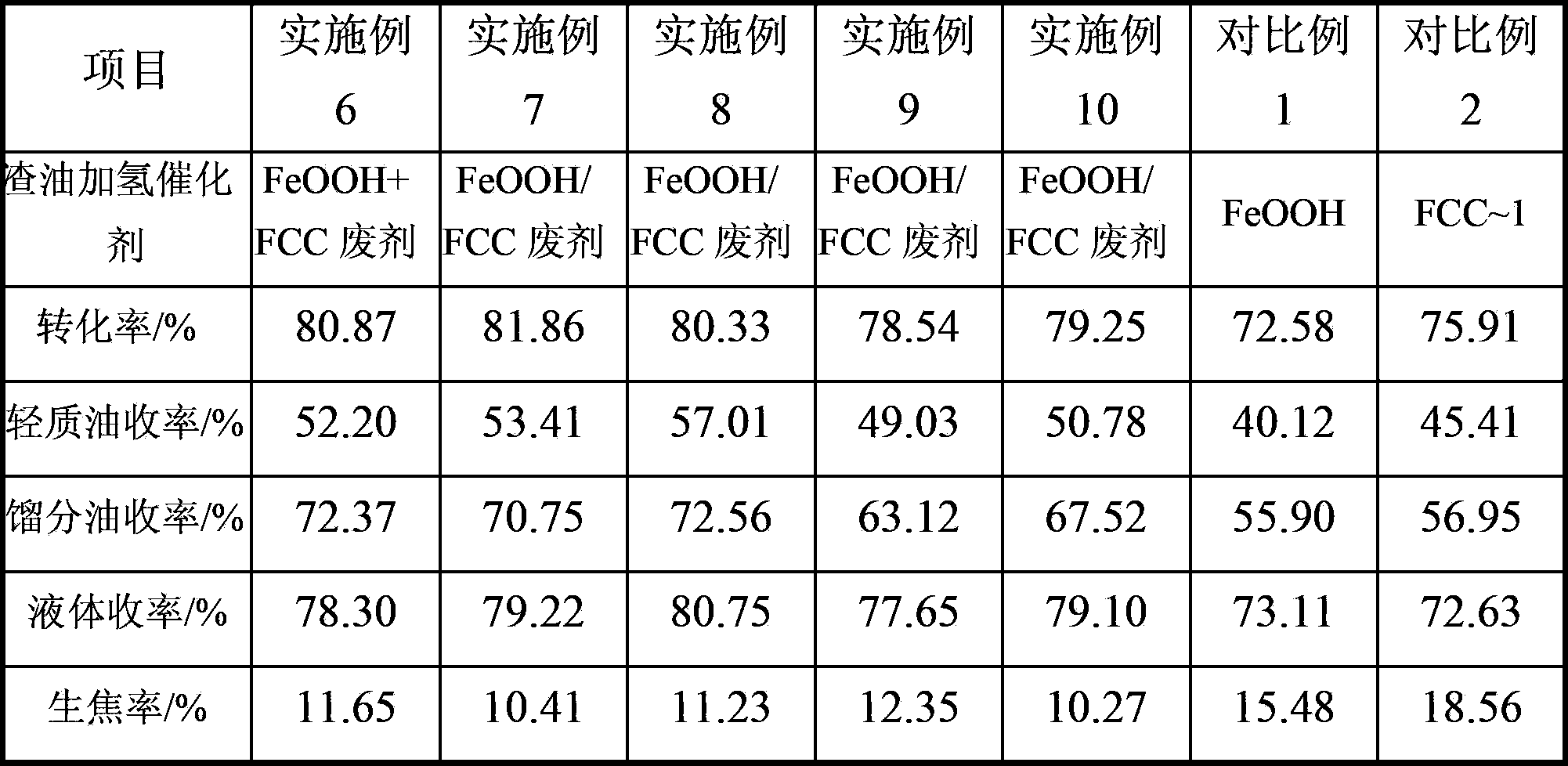

Examples

Embodiment 1

[0056] 50.0g of ferrous sulfate heptahydrate and 0.20g of EDTA were dissolved in 400g of deionized water, stirred evenly, another 25.0g of ammonia water was dripped into the above solution while stirring, air was introduced and continued to stir for 20min, then suction filtration and washing were carried out to obtain The filter cake was dried at 105°C for 2 hours, crushed and sieved to obtain a powdery iron-containing compound, denoted as Fe~1. The prepared Fe~1 and FCC-1 were mixed at a ratio of 1:5 to obtain residue hydrogenation catalyst A1.

Embodiment 2

[0058] Weigh 35g of ferrous sulfate heptahydrate and 0.12g of ammonium dihydrogen phosphate into a beaker, add 200g of deionized water and stir continuously to dissolve, weigh 50.0g of FCC~1 agent and add to the above solution, add 17g of ammonia water drop by drop while stirring After the dropwise addition, the air was introduced and continued to stir for 20 minutes, then suction filtered and washed to obtain a filter cake which was dried at 105° C. for 3 hours, pulverized and sieved to obtain the residual oil hydrogenation catalyst A2. The content of hydrated iron oxide in A2 is 18.2wt%, and the content of spent catalytic cracking catalyst is 81.8wt%.

Embodiment 3

[0060] Weigh 9.4g of ferrous acetate and 0.05g of EDTA into a beaker, add 100g of deionized water and stir continuously to dissolve, weigh 50.0g of FCC ~ 1 dosage and add it to the ferrous sulfate solution, add 7.0g of ammonia water drop by drop while stirring, drop After the addition, air was introduced and stirring was continued for 30 minutes, then suction filtered and washed to obtain a filter cake which was dried at 105°C for 2 hours, pulverized and sieved to obtain a residual oil hydrogenation catalyst which was designated as A3. The content of hydrated iron oxide in A3 is 8.5wt%, and the content of spent catalytic cracking catalyst is 91.5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com