Hydrophilic and hydrophobic interpenetrating network nanofiber, forward osmosis membrane and preparation method

An interpenetrating network, forward osmosis membrane technology, applied in the field of high flux forward osmosis membrane, can solve the problems of internal concentration polarization, high cost, hydrophilicity, poor permeability, etc., and achieve the reduction of internal concentration polarization , The effect of enhanced chlorine resistance and increased water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

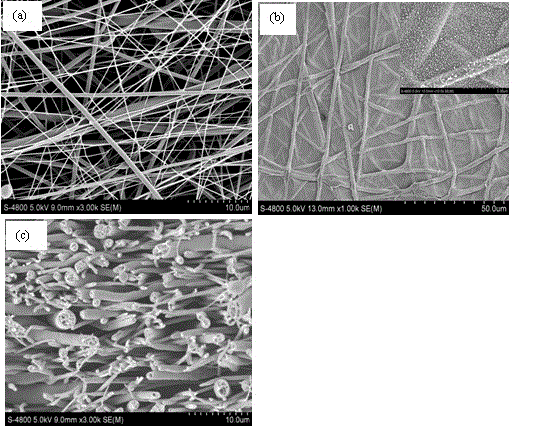

Image

Examples

Embodiment 1

[0047] Dissolve 10g of PET in 90ml of trifluoroacetic acid to prepare a 10wt% PET solution; dissolve 1g of polyvinyl alcohol (PVA) in 9ml of deionized water to obtain a 10wt% uniform solution of PVA. The two solutions were added to different syringes, the mass ratio of PET solution and PVA solution in the syringe was 4 / 1, the injection speed was 10.5μl / min, the distance between the syringe and the metal rotating drum was 15cm, and under the DC voltage of 15KV, the hydrophilic and hydrophobic Composite nanofibers were received up to 0.5m 2 On a metal rotating drum, the composite nanofibers were rinsed with deionized water for 30 minutes, then dried in a vacuum oven at 30°C for 5 hours, and finally stored in a desiccator for use.

[0048] Prepare 3.4wt% MPD / water solution, 0.1wt% TMC / n-hexane solution, soak the composite nanofiber support layer in the MPD solution for 5 minutes, drain the excess water on the surface of the support layer after taking it out, and then soak it in t...

Embodiment 2

[0051] Dissolve 10g of PET in 40ml of trifluoroacetic acid to prepare a 20wt% PET solution; dissolve 1g of PVA in 9ml of deionized water to obtain a 10wt% uniform solution of PVA. The two solutions were added to different syringes. The mass ratio of PET solution to PVA solution in the syringe was 3 / 1, the injection speed was 10.5μl / min, the distance between the syringe and the metal rotating drum was 15cm, and the hydrophilic and hydrophobic Composite nanofibers were received up to 0.5m 2 On a metal rotating drum, the composite nanofibers were rinsed with deionized water for 30 minutes, then dried in a vacuum oven at 30°C for 5 hours, and finally stored in a desiccator for use.

[0052] Prepare 3.4wt% MPD / water solution, 0.1wt% TMC / n-hexane solution, soak the composite nanofiber support layer in the MPD solution for 5 minutes, drain the excess water on the surface of the support layer after taking it out, and then soak it in the TMC solution for 30s , so that the two monomers...

Embodiment 3

[0055] Dissolve 1g of PET in 4ml of trifluoroacetic acid to prepare a 20wt% PET solution; dissolve 15g of PVA in 85ml of deionized water to obtain a 15wt% uniform solution of PVA. The two solutions were added to different syringes. The mass ratio of PET solution to PVA solution in the syringe was 1 / 4, the injection speed was 10.5μl / min, and the distance between the syringe and the metal rotating drum was 15cm. Under the DC voltage of 15KV, the hydrophilic and hydrophobic Composite nanofibers were received up to 0.5m 2 On a metal rotating drum, the composite nanofibers were rinsed with deionized water for 30 minutes, then dried in a vacuum oven at 30°C for 5 hours, and finally stored in a desiccator for use.

[0056] Prepare 3.4wt% MPD / water solution, 0.1wt% TMC / n-hexane solution, soak the composite nanofiber support layer in the MPD solution for 5 minutes, drain the excess water on the surface of the support layer after taking it out, and then soak it in the TMC solution for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com