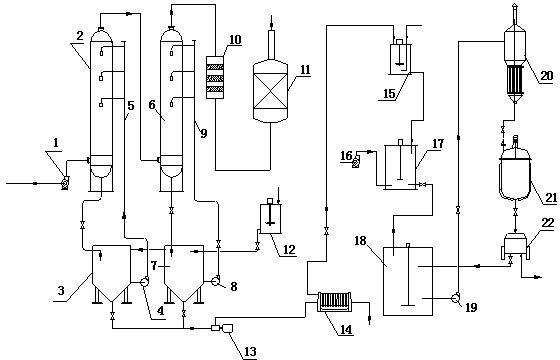

Synergetic purification method and device for SO2 and heavy metals in smelting flue gas

A technology for smelting flue gas and heavy metals, applied in chemical instruments and methods, fertilization devices, separation methods, etc., can solve the problems of large fluctuations in gas volume and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In this embodiment, the zinc smelting flue gas is used as the processing object, and the SO in the zinc smelting flue gas 2 : 4~8%, Hg: 5mg / m 3 , As: 1~5mg / m 3 , Pb: 5~8 mg / m 3 , Cd: 2~7 mg / m 3 , Zn: 20~30 mg / m 3 ; Concretely include the following steps:

[0059] (1) After preliminary dedusting of the smelting flue gas, further cool the flue gas temperature to 50°C;

[0060] (2) Fully contact the cooled flue gas with the atomized ammonium sulfide solution with a pH value of 7, and the 2 The smelting flue gas is absorbed, and the metal oxides in the flue gas are absorbed at the same time. The purified flue gas is discharged after deep heavy metal removal by the fixed bed catalytic heavy metal removal device, and the mass percentage concentration of the ammonium sulfide solution is 8%;

[0061] (3) Absorbed SO 2After the rich liquid with heavy metals is filtered through pressure filtration, the precipitates of heavy metal sulfides in the solution are filtered, and ...

Embodiment 2

[0068] This embodiment takes the lead smelting flue gas as the processing object, and the SO in the lead smelting flue gas 2 : 8~12%, Hg: 2~5mg / m 3 , As: 1~5mg / m 3 , Pb: 35~45mg / m 3 , Cd: 1~3 mg / m 3 , Zn: 1~5 mg / m 3 Specifically include the following steps:

[0069] (1) After preliminary dedusting of the smelting flue gas, further cool the flue gas temperature to 40°C;

[0070] (2) Fully contact the cooled flue gas with the atomized ammonium sulfide solution with a pH value of 7, and the 2 The smelting flue gas is absorbed, and the metal oxides in the flue gas are absorbed at the same time. The purified flue gas is discharged after deep heavy metal removal by the fixed bed catalytic heavy metal removal device, and the mass percentage concentration of the ammonium sulfide solution is 25%;

[0071] (3) Absorbed SO 2 After the rich liquid with heavy metals passes through pressure filtration, the precipitate of heavy metal sulfide in the solution is filtered, and the filter...

Embodiment 3

[0078] In this embodiment, the nickel smelting flue gas is used as the treatment object, and the SO in the nickel smelting flue gas 2 : 0.8~2.0%, Hg: 1~4mg / m 3 , As: 3~5mg / m 3 , Pb: 10~25mg / m 3 , Cd: 1~3 mg / m 3 , Zn: 2~6mg / m 3 ; Concretely include the following steps:

[0079] (1) After preliminary dedusting of the smelting flue gas, further cool the flue gas temperature to 30°C;

[0080] (2) Fully contact the cooled flue gas with the atomized ammonium sulfide solution with a pH value of 6, and the 2 The smelting flue gas is absorbed, and the metal oxides in the flue gas are absorbed at the same time. The purified flue gas is discharged after deep removal of heavy metals by a fixed-bed catalytic mercury removal device, and the mass percentage concentration of ammonium sulfide solution is 15%;

[0081] (3) Absorbed SO 2 After the rich liquid with heavy metals passes through pressure filtration, the precipitates of heavy metal sulfides in the solution are filtered, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com