Wadding wire composite filter stick for cigarettes and filter tip thereof

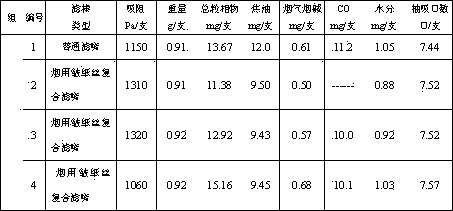

A composite filter rod and tobacco paper technology, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problem of insufficient filtering effect, and achieve the effects of easy realization of large-scale production, improvement of coke reduction effect, and expansion of application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

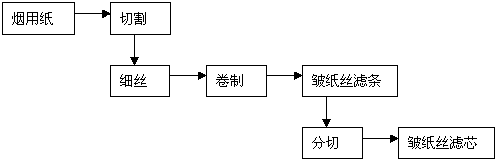

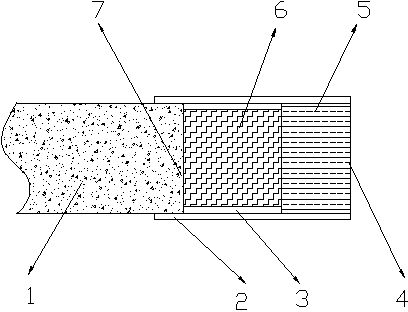

[0034] use as figure 1 The crepe paper composite filter rod for cigarettes produced by the production process shown is made of crepe paper filter element 6 and the end face of acetate fiber filter element 5, which are spliced together and wrapped in the same outer ring forming paper 2.

[0035] The crepe paper filter element 6 is made of cigarette paper (in the papermaking process of cigarette paper, wood pulp fiber is used as the main raw material, doped with a small amount of carbon fiber, and the doping ratio is 15-30%; it is also sprayed with granular additives). The cigarette paper is first crumpled, and the wrinkle depth formed by crumpling is 400~800μm; then cut into filaments with a width of 0.3-1.0mm and a length of 10-20mm, and then use a cigarette tipping machine to sort irregular filaments The roll is made into a fluffy degree or a density of 1.5g / cm 3 The crepe paper silk filter strip is finally cut into the designed length to form the crepe paper silk filter ...

Embodiment 2

[0037] like figure 2 The shown composite filter of crepe paper for cigarettes is made by cutting the composite filter rod of crepe paper for cigarettes in the above-mentioned embodiment 1, and then installed on cigarettes for use; the composite filter of crepe paper contains at least a section of vinegar A fiber filter element 5 and a section of crepe paper filter element 6; the crepe paper filter element 6 is individually wrapped with an inner ring forming paper 3, and the crepe paper filter element 6 is connected to the end 7 near the shredded tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com