Printed circuit board and manufacturing method thereof

A technology for printed circuit boards and manufacturing methods, which is applied in the direction of multilayer circuit manufacturing, printed circuit components, conductive pattern formation, etc., and can solve the problems of inability to apply miniaturized electronic devices, increase the volume of printed circuit boards, and increase the thickness of printed circuit boards and other problems, to achieve the effect of saving professional electroplating equipment, saving materials, and increasing the number of layers of conductive lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

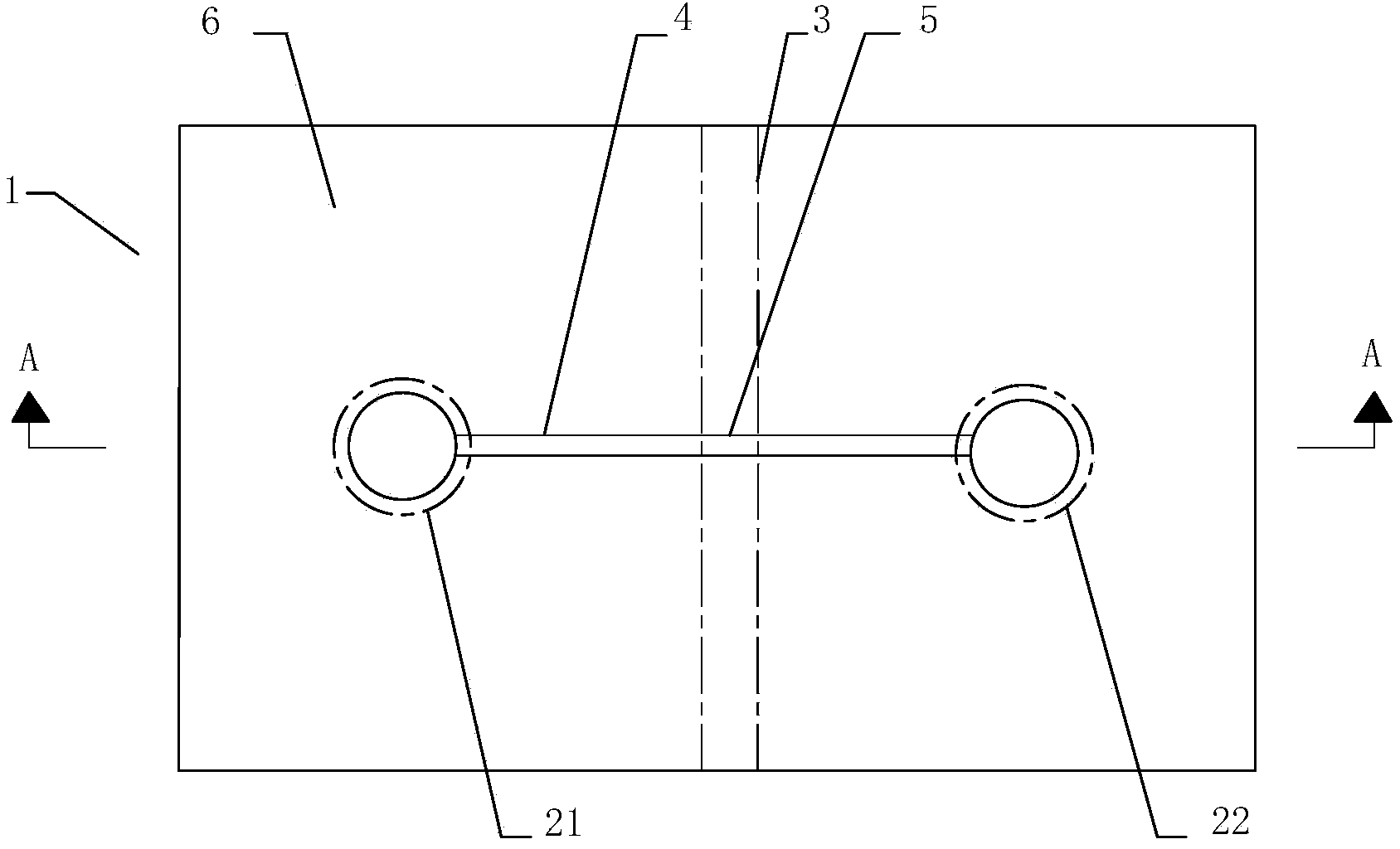

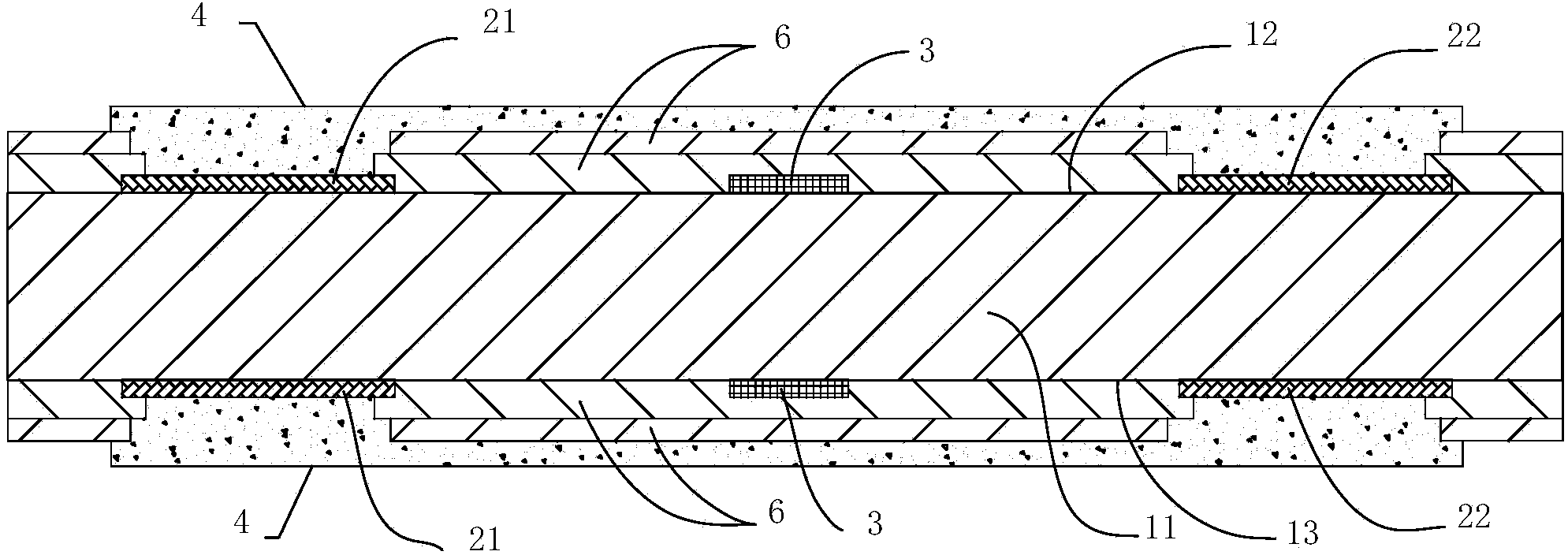

[0033] Such as figure 1 and 2 As shown, the printed wiring board 1 includes a substrate 11 . Both the upper surface 12 and the lower surface 13 of the substrate 11 are provided with two layers of conductive circuits, namely the first layer of conductive circuits 3 and the second layer of conductive circuits 4 . The conductive lines 3 of the first layer and the conductive lines 4 of the second layer are stacked and intersect each other. The intersection of the first-layer conductive circuit 3 and the second-layer conductive circuit 5 is separated by an insulating material layer 6 . The insulating material layer 6 is non-conductive epoxy resin. Both the upper surface 12 and the lower surface 13 of the substrate 11 are provided with a first copper disk 21 and a second copper disk 22 , and the first copper disk 21 and the second copper disk 22 are electrically connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com