Electronic ink, electronic paper and method for preparing electronic ink

A technology of electronic ink and electrophoresis, applied in nonlinear optics, instruments, optics, etc., can solve the problems of slow speed, poor image definition of display devices, and slow response speed of display devices, so as to improve response speed and image clarity Degree, the effect of purifying air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

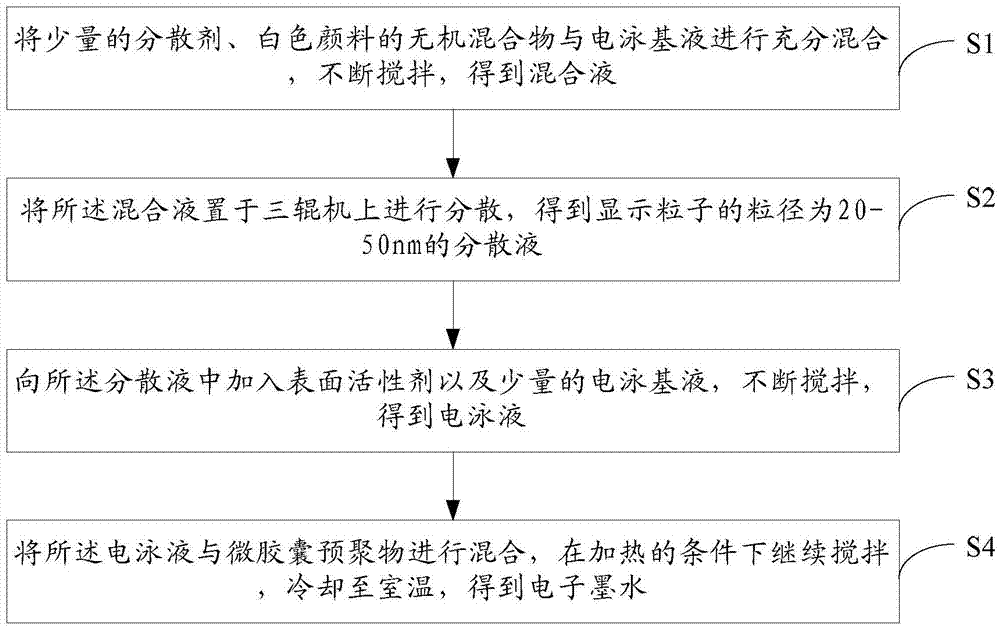

[0068] The embodiment of the present invention provides a preparation method of electronic ink. The various components in the white pigment used in the preparation method and the selected organic solvent come from a wide range of sources, and the process is simple and easy to operate. Since the display particles in the electronic ink are inorganic mixtures with a particle size between 20-50nm, the particle size of the display particles is small enough and the quality of the display particles thus formed is uniform. The charge shows that the particles are capable of uniform and rapid directional migration. The display device prepared by the method not only improves the response speed, but also further improves the image definition thereof. In addition, because the method can also generate high-concentration negative ions during the implementation process, it also has the function of purifying the air quality in the production workshop.

[0069] It should be noted here that, in...

Embodiment 1

[0081] Electronic Ink 1

[0082] First, weigh 9 parts of zinc oxide, 0.03 parts of boron oxide, 0.12 parts of lithium oxide and 0.15 parts of zirconia, add a small amount of Solsperse3250 to disperse, and then add 40.05 parts of bromobenzene for continuous stirring, and then place it on a three-roll machine Continue to disperse to obtain a dispersion; then add 0.12 parts of a fluorocarbon surfactant, 1.5 parts of a toluenesulfonate surfactant and 43.03 parts of bromobenzene to the dispersion to continuously stir to obtain an electrophoretic liquid; finally, add 6 parts of the microcapsule prepolymer were mixed with the electrophoretic solution and stirred continuously for 1 hour at 40° C. to obtain electronic ink 1 .

Embodiment 2

[0084] E Ink 2

[0085] First, weigh 9 parts of zinc sulfide, 0.03 parts of boron oxide, 0.22 parts of lithium oxide and 0.15 parts of zirconia, add a small amount of Solsperse3250 to disperse, and then add 39.78 parts of bromobenzene for constant stirring, and then place it on a three-roll machine Continue to disperse to obtain a dispersion; then add 0.12 parts of a fluorocarbon surfactant, 2 parts of a toluenesulfonate surfactant and 42.7 parts of bromobenzene to the dispersion to continuously stir to obtain an electrophoretic liquid; finally, add 6 parts of the microcapsule prepolymer were mixed with the electrophoretic liquid, and stirred continuously for 1 hour under the condition of 42° C. to obtain electronic ink 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com