Optical cable fiber distribution box

A fiber distribution box and optical cable technology, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of affecting the sealing of the box, box leakage, and increasing the manufacturing cost of the fiber distribution box, and achieves convenient and flexible jumpers, convenient installation, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

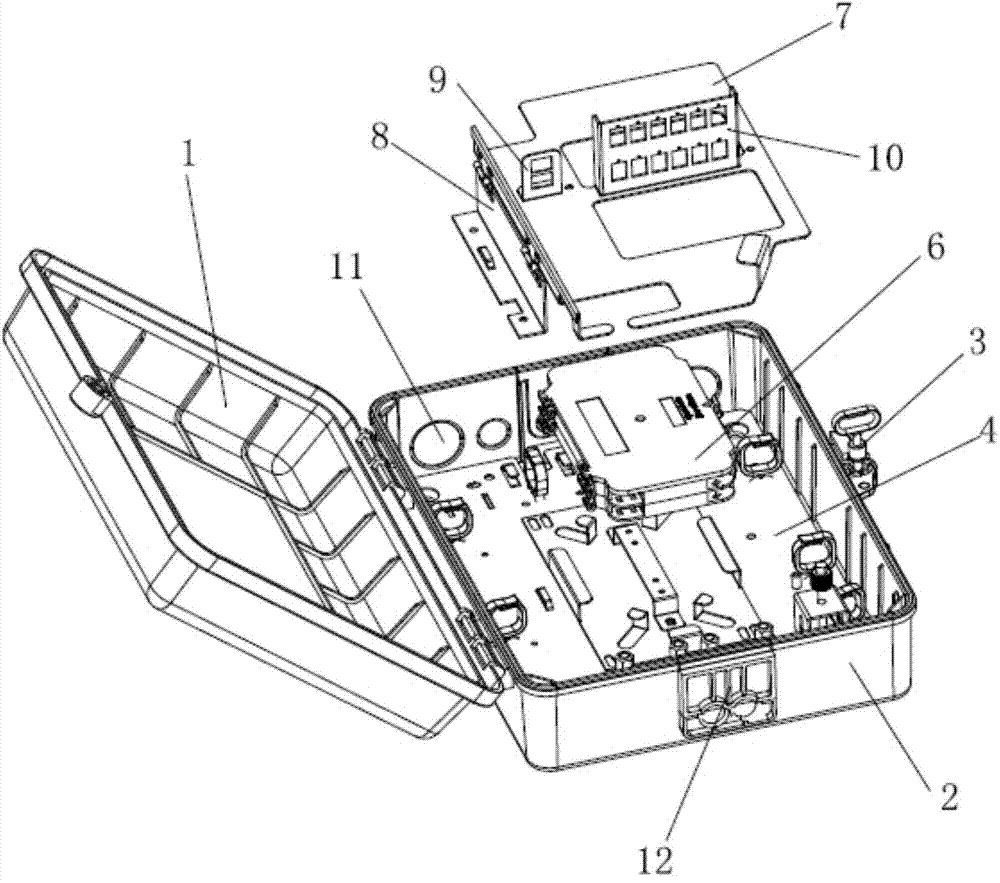

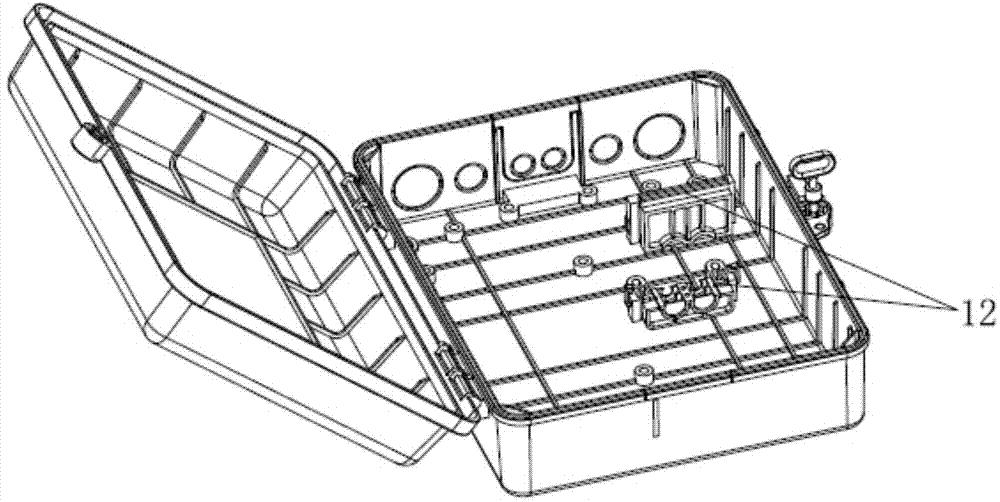

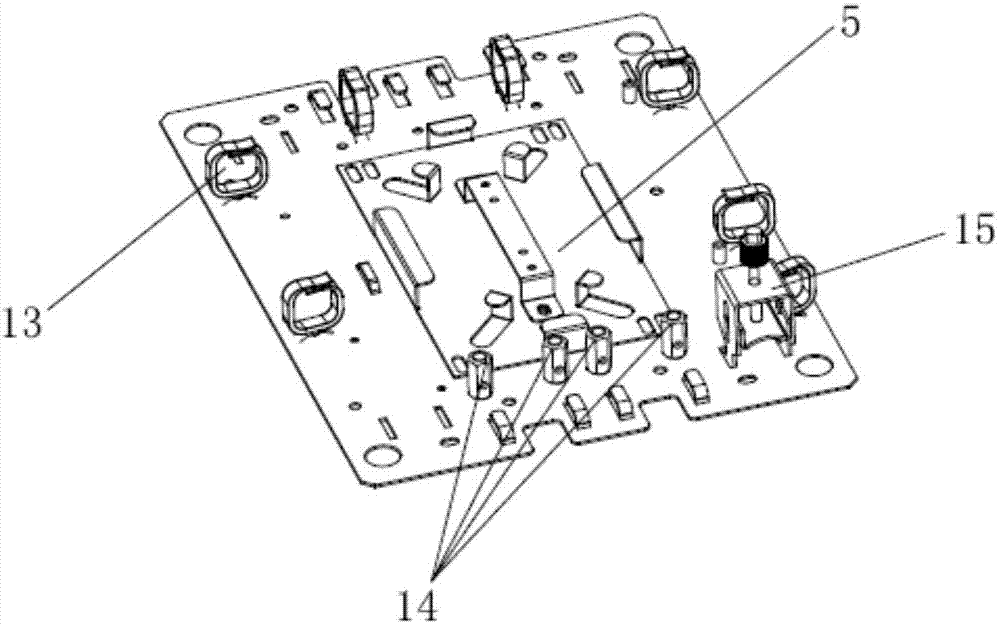

[0018] Attached below figure 1 to attach image 3 The technical solutions of the present invention are further described through specific implementation methods.

[0019] An optical fiber distribution box, comprising a box body 2 and a box cover 1 hinged to the box body 2, one side of the box body 2 and the box cover 1 is provided with a lock for locking the box body 2 and the box cover 1 Tightening device 3, a detachable inner plate 4 is fastened on the inner bottom surface of the box body 2, an optical fiber fusion splicing area and an optical cable storage area are arranged on the inner plate 4, and a fiber storage plate 5 is arranged on the optical fiber fusing area The fiber storage plate 5 is provided with a superimposed and reversible fusion splice tray 6, the top of the fusion splice tray 6 is provided with a reversible upper layer plate 7, and one side of the upper layer plate 7 is provided with a locking structure, so The other side of the upper deck 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com