Extensometer and its measurement method

A measurement method, extensometer technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of complex testing methods, low testing efficiency, low precision, etc., to achieve more accurate Functional test, improved test environment adaptability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

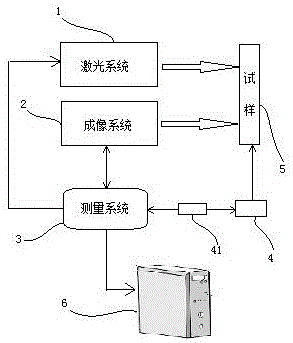

[0018] figure 1 is a schematic diagram of the extensometer of the present invention, combined with figure 1 The structure of the extensometer of this invention is demonstrated.

[0019] Such as figure 1 The shown extensometer includes: a laser system 1, the laser system 1 is used to generate laser light on the test sample 5 of the test machine; an imaging system 2, the imaging system 2 is used to capture the image of the test sample 5 Image; measurement system 3, the measurement system 3 is used to test image acquisition control and image signal processing, obtain measurement data, and output the data; the measurement system 3 is related to the laser system 1 and the imaging system 2 connect. When testing the sample, the measuring system 3 is connected to the testing machine 4 through the testing machine interface 41 .

[0020] In the extensometer of the present invention, the laser system 1 includes a laser light source device, the laser light source is a continuous laser...

Embodiment 2

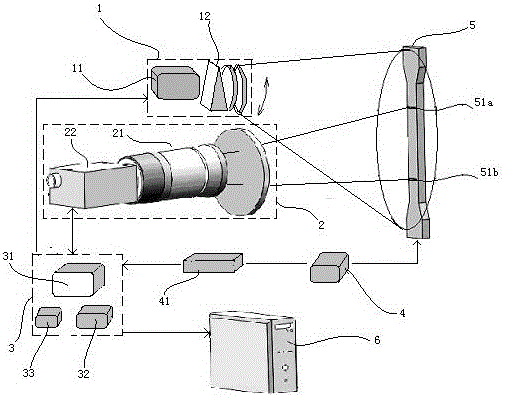

[0025] attached figure 2 It is a structural schematic diagram of the extensometer of this embodiment, combined with the attached figure 1 , attached figure 2 The structure and measurement method of the extensometer of the present invention will be further described. Such as figure 1 As shown, the extensometer includes a laser system 1, an imaging system 2, and a measurement system 3. During use, the measurement system 3 is connected to the test machine 4 through the test machine interface 41. The test system of the extensometer can be connected with the computer platform 6.

[0026] In the present invention figure 2 Among them, the sample 5 to be tested is shown in the figure, and test marks 51a, 51b are set on the sample 5, and the marks 51a, 51b set on the sample 5 are bar-shaped marks, and the edges of the two-shaped marks are demarcated Obvious and approximately parallel, and perpendicular to the loading direction of the sample; you can choose to use different mark...

Embodiment 3

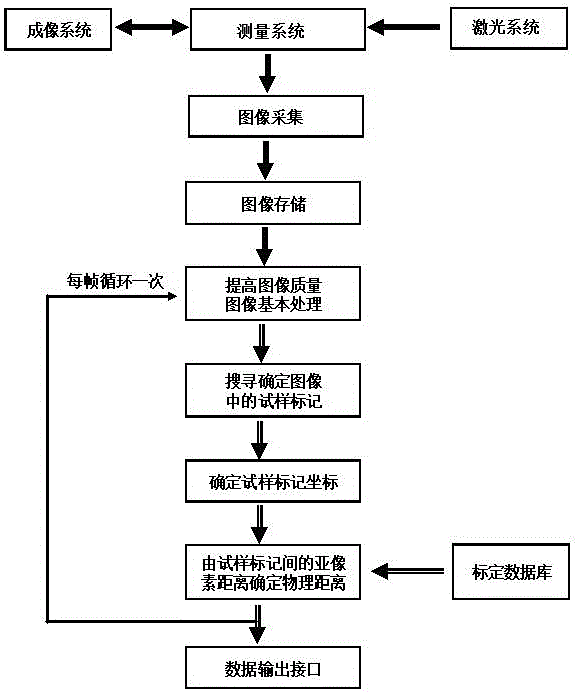

[0035] Such as image 3 It is a schematic diagram of the working principle of the dynamic measurement of the measurement system of the present invention. In combination with the schematic diagram, in this embodiment, the steps of the specific measurement method for testing with the extensometer of the present invention are further described.

[0036] In the measurement using the extensometer of the present invention, the steps are as follows: set the sample 5: set the test marks 51a, 51b on the sample 5 to be tested, and fix the sample on the testing machine 4, so that the The above test marks 51a, 51b are always kept within the imaging range of the imaging device 21; adjust the laser system 1: select the laser light source 11 with corresponding power according to the size of the sample 5, adjust the laser beam, and irradiate the laser beam directly on the sample 5 Make the plane of the sample 5 substantially perpendicular to the optical axis; adjust the imaging system 2: thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com