A one-way explosion transfer door element and a method for realizing one-way reliable explosion transmission of an explosion network using the element

A door component, one-way technology, applied in the field of one-way reliable explosion transmission and one-way explosion transmission door components, can solve the problems of retrieval and other problems, and achieve the effect of preventing major safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

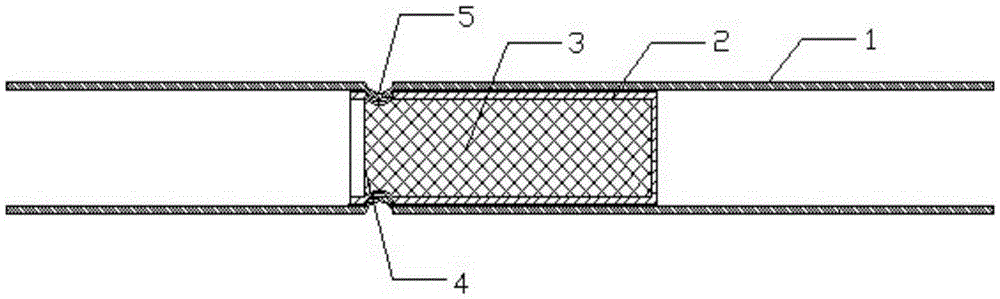

[0029] figure 1 Among them, 1 is a cylindrical shell, made of aluminum, with a smooth surface, no cracks and blisters, and its molding dimensions are: outer diameter 6.1mm, inner diameter 6.0mm, height 70mm. A flameproof body 2 is installed in the middle of the shell, and the shell of the flameproof body 2 is made of iron, with an outer diameter of 5.9mm, an inner diameter of 5.8mm, and a height of 25mm; 3 (3:1) mixed components with a density of 0.8g / cm 3 , The filling height is 23mm. Booster 3 is sealed with wax paper 4, leaving a gap of 2mm above 4, and 5 is the bayonet treatment between the flameproof body and the shell to fix the position of the flameproof body in the shell.

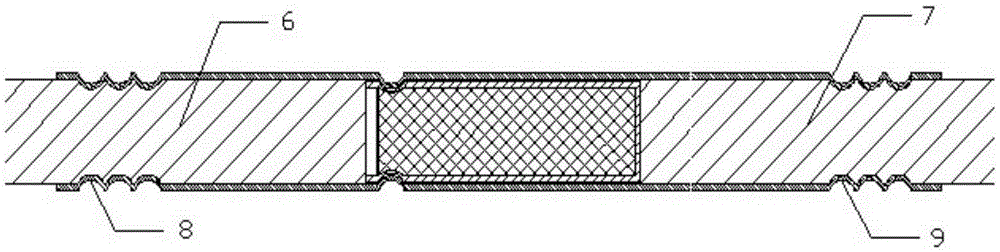

[0030] When used in the field, 6 and 7 ( figure 2 ) is the detonating cord connected to both sides of the flameproof body, 8 and 9 are the interference fit positions between the detonating cord and the shell, so that the detonating cord and the shell are tightly connected. When detonating, 6 pl...

Embodiment 2

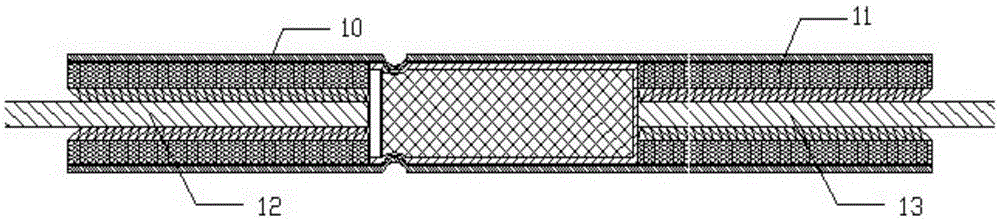

[0032] image 3 Among them, 1 is a cylindrical shell, made of iron, with a smooth surface, no cracks and blisters, and its molding dimensions are: outer diameter 12.1mm, inner diameter 12.0mm, height 60mm. A flameproof body 2 is installed in the middle of the shell. The shell of the shell is made of aluminum, with an outer diameter of 11.9mm and an inner diameter of 11.8mm. The booster 3 is made of 0.8g PETN and KClO 4(3:1) mixed components with a density of 0.8g / cm 3 , The filling height is 9mm. The booster is sealed by wax paper 4, and there is a gap of 3mm above the wax paper, and seals 10 and 11 are loaded into both sides of the flameproof body. The seal is 24mm long, with an outer diameter of 11.9mm and an inner diameter of 4.0mm. It is made of rubber. It cannot be pulled out, so as to realize the purpose of quick connection between the detonating cord and the one-way explosion door. The outer diameter of the sealing member is interference fit with the shell, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com