Cabinet type biomass hot blast stove

A technology of biomass and hot blast stoves, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of black smoke, large smoke resistance, and too fast smoke rise, and achieve moderate combustion temperature, Lower exhaust gas temperature, simple effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

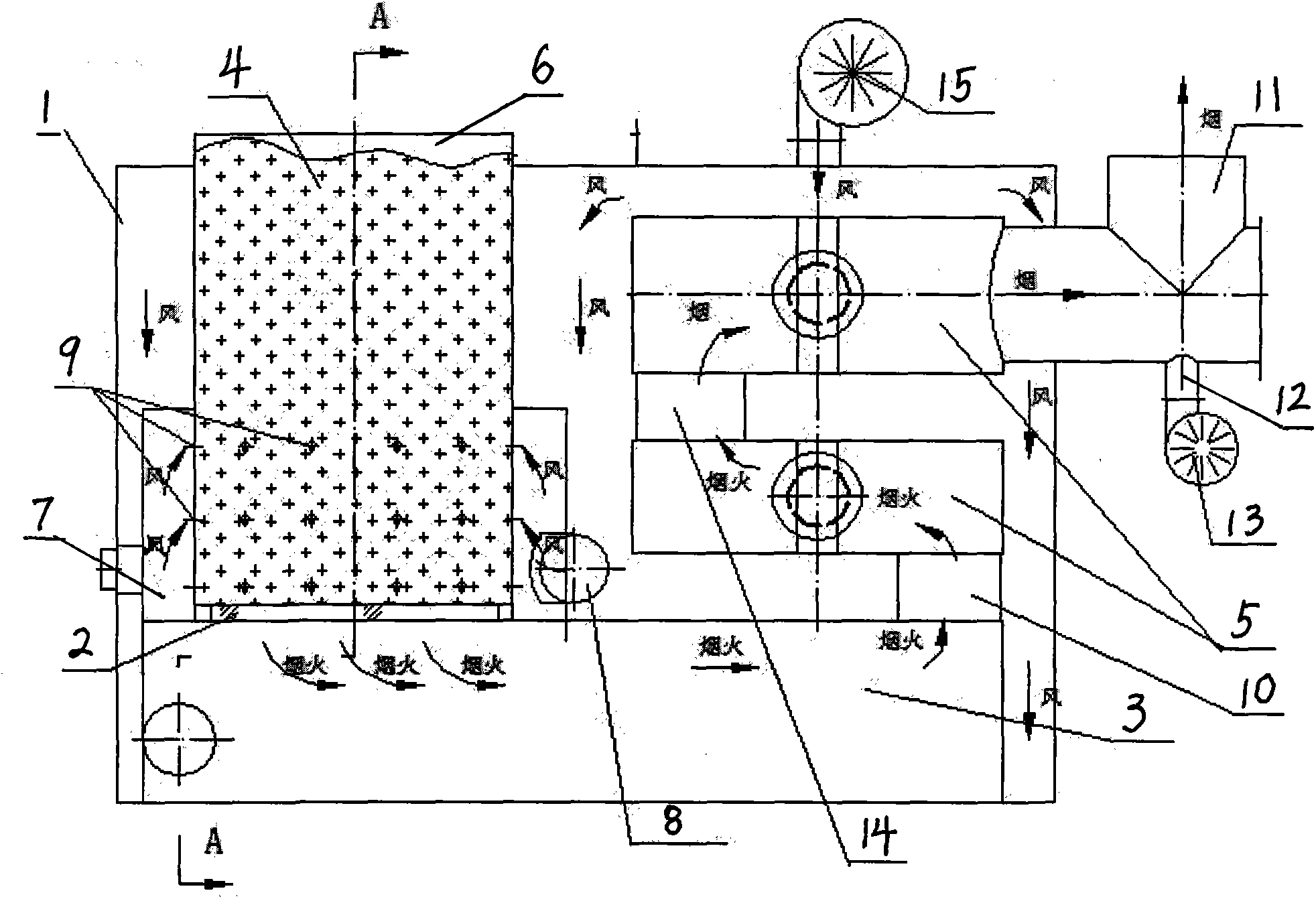

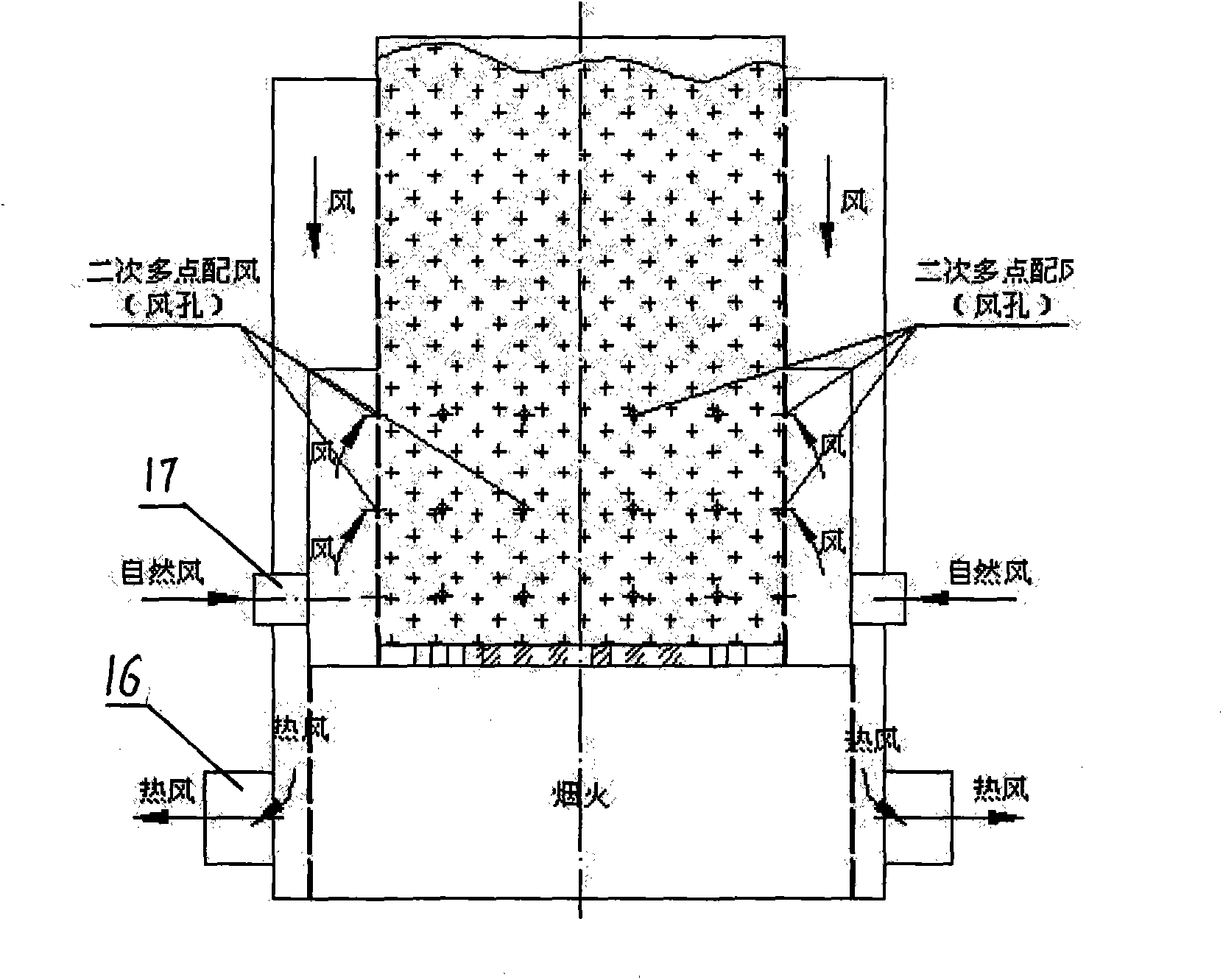

[0015] See figure 1 , figure 2 , the cabinet-type biomass hot blast stove disclosed by the present invention includes a cabinet body 1, a furnace grate 2 is fixed at the lower part of the cabinet body 1, and the combustion chamber 3 is located below the furnace grate 2 in the cabinet body 1, and the inside of the cabinet body 1 The grate 2 above the combustion chamber 3 is respectively provided with a fuel cylinder 4 and a multi-layer heat exchange rotating inner tank 5, and the fuel cylinder 4 and the multi-layer heat exchange rotating inner tank 5 are respectively arranged on both sides of the cabinet body 1, The upper end of the fuel cylinder 4 protrudes out of the cabinet 1, the upper port of the fuel cylinder 4 is provided with a cylinder cover 6, the lower ring of the outer wall of the fuel cylinder 4 is provided with a secondary air box 7, and the secondary air box 7 is connected to the fuel cylinder 4. Airtight connection, there is an air inlet on the secondary air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com