Multi-way valve and hydraulic control system

A multi-way valve and total control technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve problems such as complex pipelines, and achieve the effect of simple connection pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

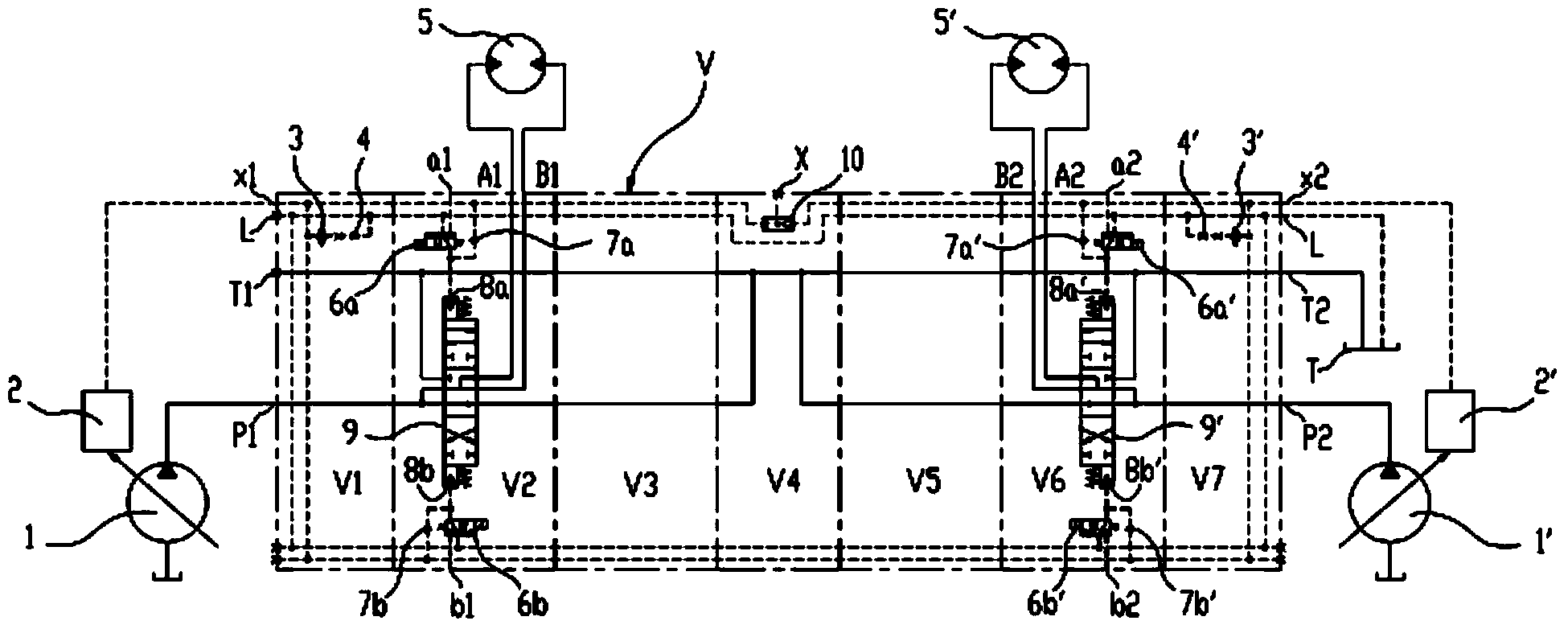

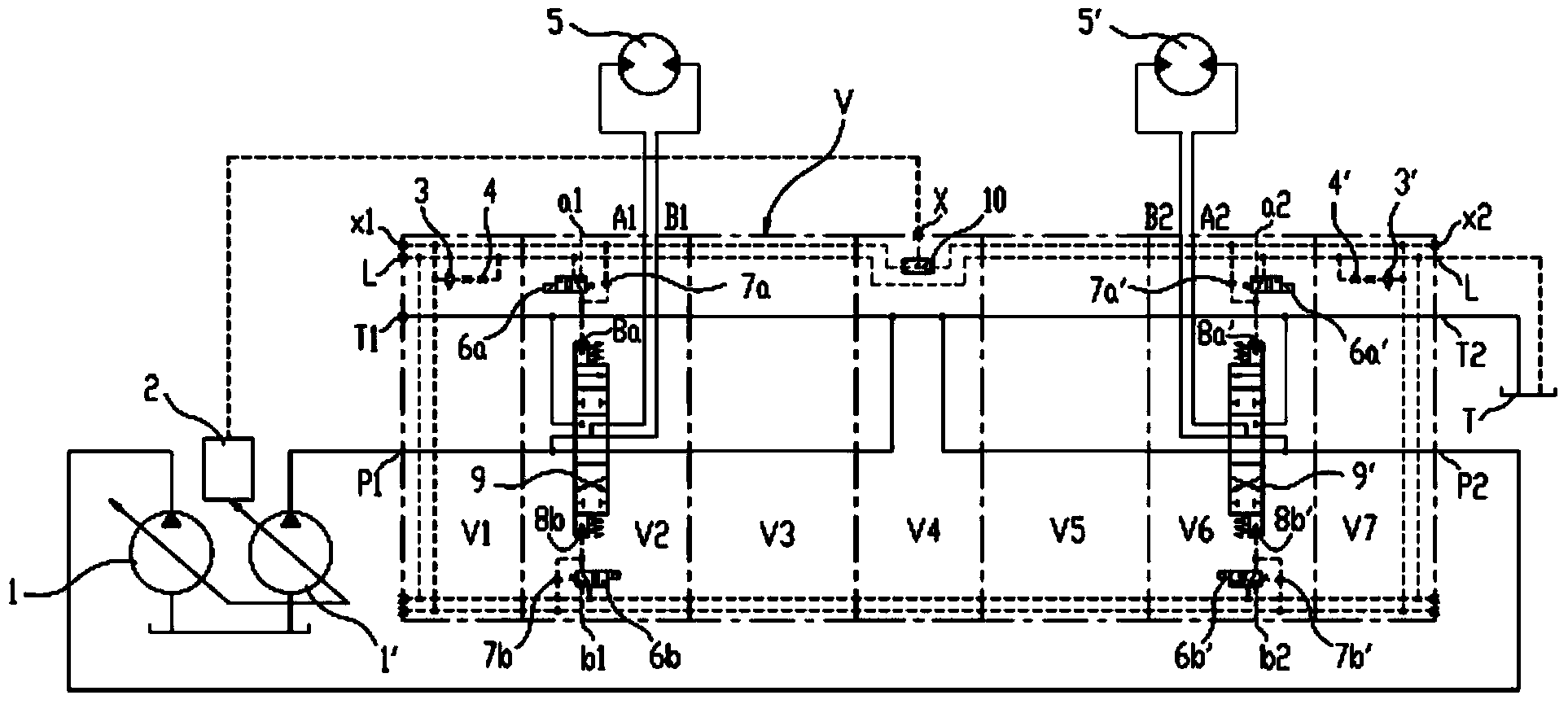

[0032] The present invention provides a kind of multi-way valve, adopts such as figure 2 and image 3 A combination of multiple worksheets shown in . exist figure 2 and image 3 Among them, the multi-way valve V is composed of working couplets V1-V7, among which the working couplets V1 and V7 are used to connect the main pumps 1 and 1', so it can be called the oil inlet joint, and the working couplet V4 is between the two working couplets V2-V7. Between V3 and V5-V6, it can be called the middle joint. Among them, the main reversing valve and the corresponding pilot oil circuit switch control structure are respectively set in the working links V2-V3 and V5-V6. figure 2 and image 3 The hydraulic principle structures of the corresponding main reversing valves 9 and 9' are described by taking working links V2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com