Natural gas supply device of engine

An air supply device and natural gas technology, which is applied to oil supply devices, engine components, combustion engines, etc., can solve the problems of compact and complex overall structure, and achieve the effect of easy connection of pipelines and reduction of ventilation blind spots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

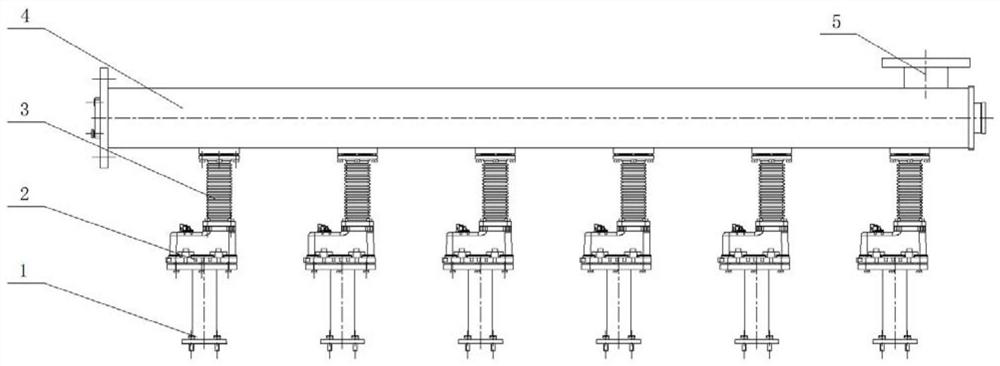

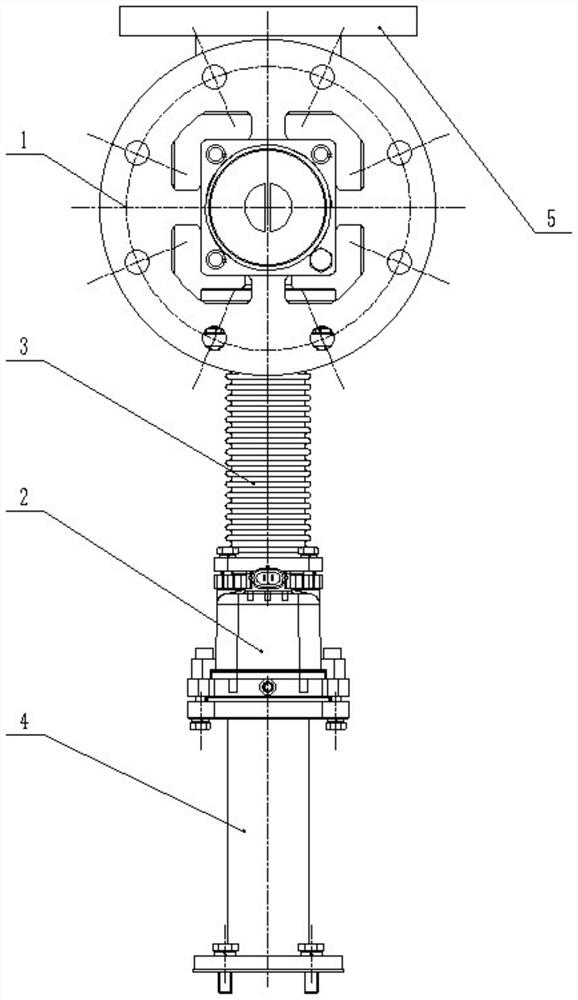

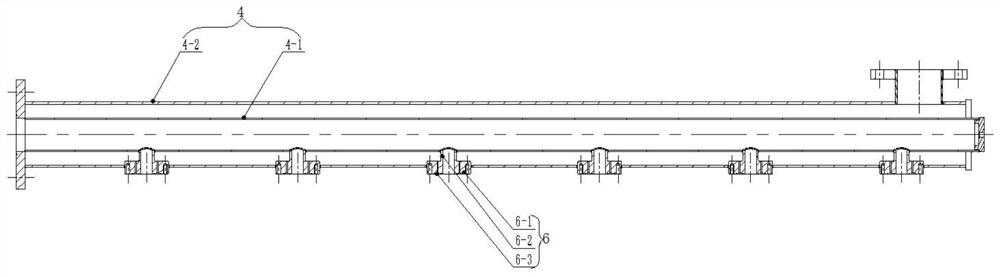

[0035] This application relates to a natural gas supply device for engines, which provides natural gas supply for dual-fuel engines. The main structure of the gas supply device is a double-wall support pipe 1, a natural gas injection valve 2, a double-wall corrugated pipe 3, and a double-wall gas supply pipe 4. There is a cylinder head that needs to be used on the engine, and several natural gas intake passages and pressurization passages are arranged on the cylinder head, so that each double-walled support pipe 1 corresponds to a natural gas intake passage, and the double-walled support pipe 1 1 is fixedly connected to the cylinder head, so that the natural gas delivery cavity in the double-walled support tube 1 communicates with the natural gas intake channel on the cylinder head, and the upper end of the double-walled support tube 1 is fixedly installed with the natural gas injection valve 2, and the natural gas injection valve 2 The upper end of the double-wall corrugated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com