Universal random deviation rectification outside injected magnetic fluid polished rod sealing device

A polished rod sealer, magnetic fluid technology, applied in sealing/isolation, wellbore/well components, earth-moving drilling, etc. The effect of improving oil and gas recovery rate, avoiding pollution and damage, and large frictional resistance

Inactive Publication Date: 2014-04-30

邓海波

View PDF7 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the packing wears to a certain extent, crude oil and high salinity formation water will leak to the ground, causing serious pollution of the surface environment; if the oil well is in the farmland, it will cause the death of crops

[0025] (2), the labor intensity of the workers is high

[0027](3), potential safety hazard

Therefore, packing leakage is a serious safety hazard in oil fields

[0029](4), increase energy consumption

[0030]During the oil extraction process of the pumping unit, whether it is an upstroke or a downstroke, the polished rod is always in the brake state of being tightly held by the packing, which increases the movement resistance, thus It also increases the energy consumption of the pumping unit

[0031](5), waste of resources

[0032] After the rubber block packing (or braided packing sealing ring) is worn out, there is a gap between it and the polished rod. As the service time prolongs, the gap continues to expand. The pressurized oil, gas, and water in the oil well continue to emerge and overflow from the gap, wasting precious resources

[0033](6), damaged polished rod

[0034]Because the polished rod is always in a state of mechanical compression and friction, the friction loss makes the polished rod change from thick to thin, and the fatigue stress causes cracks inside the polished rod. The double effect greatly shortens the polished rod. service life

[0035](7), easy to cause partial friction of the sucker rod

[0041]After laboratory tests and oilfield well field tests, it has been confirmed that the magnetic fluid sealing device designed by me is advanced and reliable; two requirements are put forward Problems to be improved: First, there will be a small loss of magnetic fluid during the reciprocating motion of the polished rod, and it needs to be replenished once every 1 to 2 years; second, the drift of the polished rod is normal during the oil pumping process, and a deflection correction device is necessary to ensure the smooth rod and seal The shell will not be scratched and damaged

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

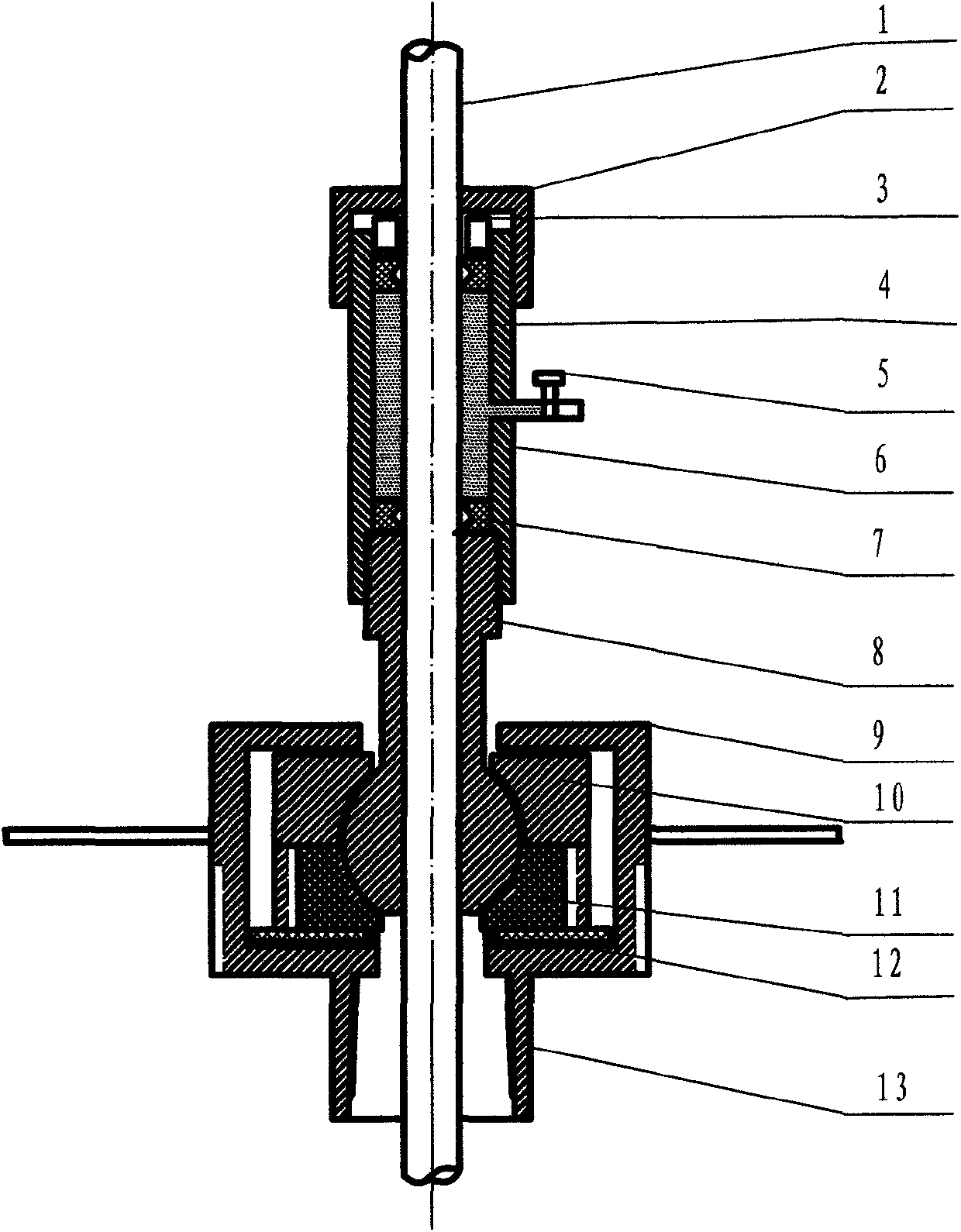

Provided is a universal random deviation rectification outside injected magnetic fluid polished rod sealing device applied for oil extraction in the oil field. The universal random deviation rectification outside injected magnetic fluid polished rod sealing device comprises a polished rod sealing culvert at the upper portion, wherein an upper and a lower group of permanent magnets are arranged in the culvert, an injection hole is formed in the middle portion capable of Is capable of injecting and supplying magnetic fluid into a cavity in due time to conduct a dynamic sealing to the polished rod, and a universal-joint mechanism at the lower portion is capable of rectifying deviation randomly in radial and axial three-dimensional space. A polished rod sealing culvert assembly is arranged above the random deviation rectification mechanism. The universal random deviation rectification outside injected magnetic fluid polished rod sealing device thoroughly resolves problems that production halts often occur due to applying packing polished rod sealing device in the existing oil extraction with huge energy consumption and easy damage, causing emitting, dipping and leakage of well mouth pressed oil, gas and water and accompanying serious environmental pollution, potential safety hazard and other world class problems, and can be widely applied in well mouth polished rod sealing of oil field sucker-rod pump oil extractor.

Description

technical field [0001] (1), technical field of the present invention: [0002] Technical field of patent description: mechanical device and transportation technical field - mechanical components - G05G - control device or system distinguished only by mechanical features. [0003] Catalog of high-tech fields of the Ministry of Science and Technology: 8. High-tech transformation of traditional industries—(4) New machinery—2. General machinery and new machinery. [0004] (two), the scope of application: [0005] The invention is a new technology of energy saving, emission reduction, safety and environmental protection in the petroleum industry, an upgraded product of the old polished rod sealer, and is suitable for the polished rod sealing of about 500,000 wells with rod pumps in more than 20 large and medium-sized oil fields across the country. [0006] (three), function: [0007] The present invention adopts the most advanced magnetic fluid sealing technology to realize "zer...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B33/03

Inventor 邓海波

Owner 邓海波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com