Large flow clapboard spraying device for deep water trenching machine

A ditching machine and clapboard-type technology, which is applied in the field of large-flow clapboard-type spraying devices for deep-water trenching machines, can solve problems such as high degree of turbulence, insufficient smoothness of the outlet flow field, influence of trench shape and construction operation effect, etc. Achieve the effect of reducing the degree of turbulence and smoothing the flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

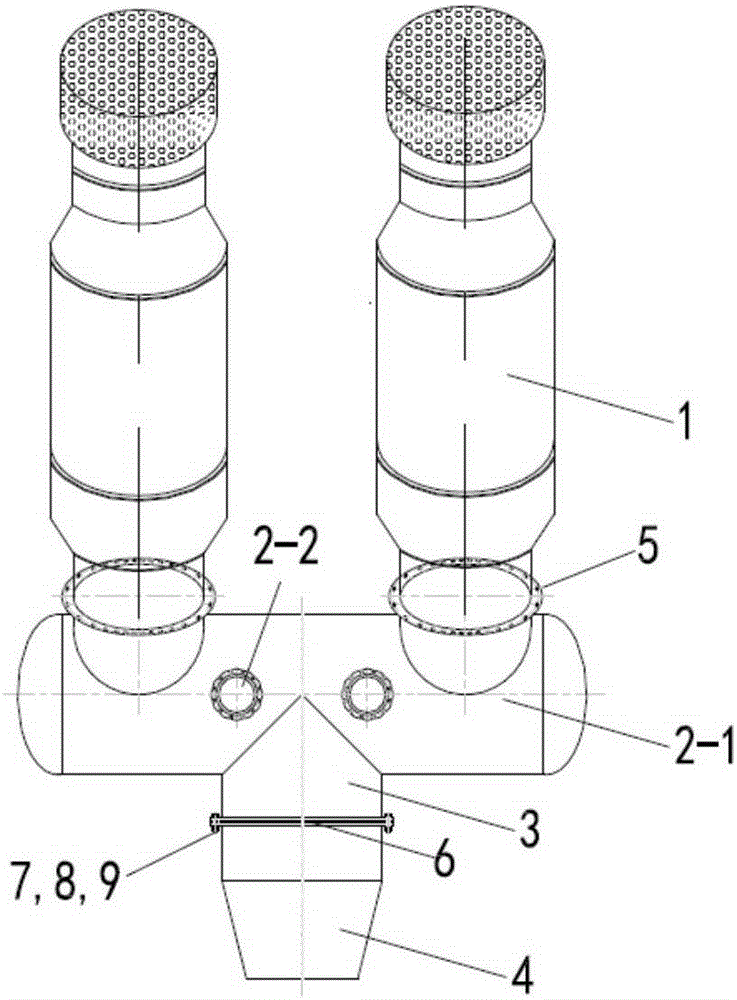

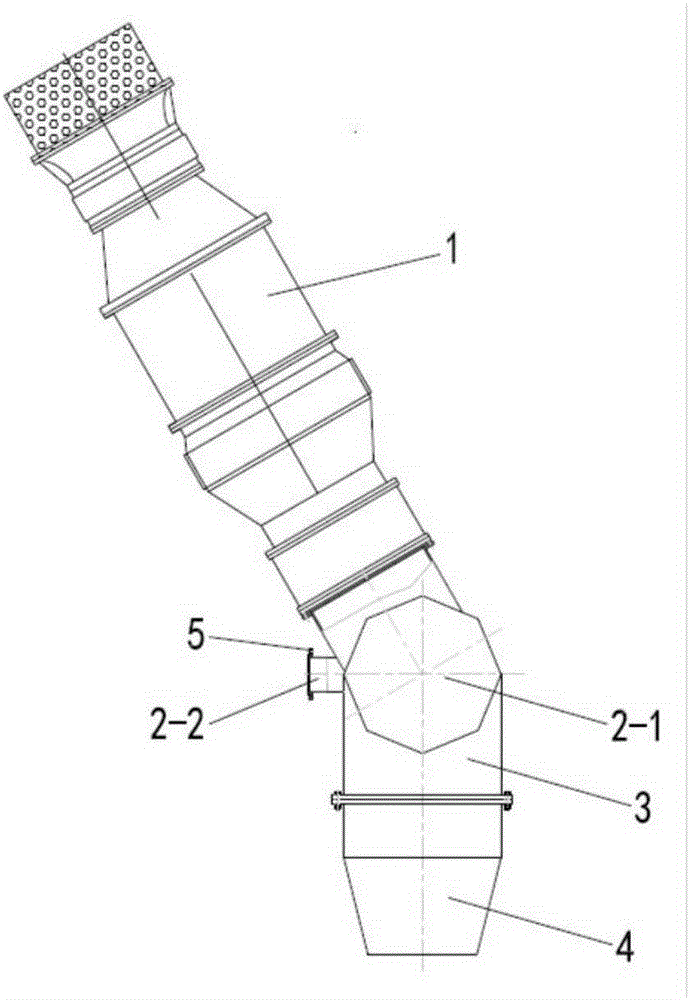

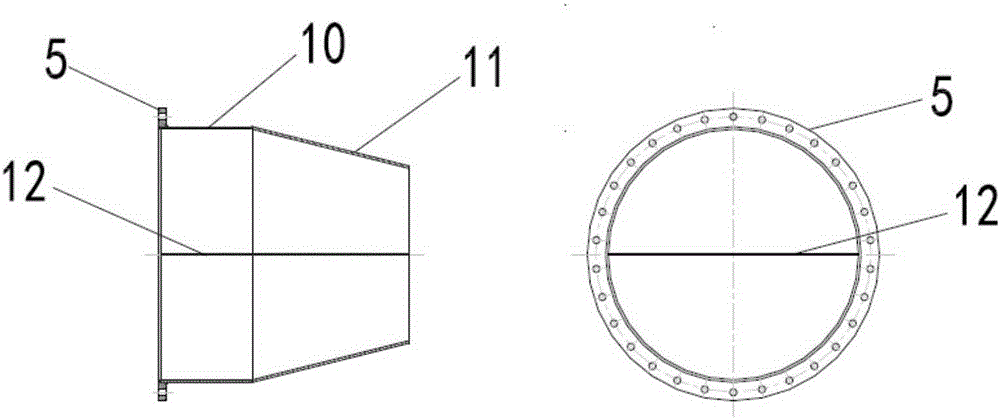

[0020] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes: an axial flow pump 1, a connecting pipe 2, a water spray pipe 3, a nozzle 4, a flange 5, a gasket 6, a bolt 7, a nut 8, and a washer 9, wherein: 2 sets turn to the same shaft The flow pumps 1 are connected in parallel to form a power device for spraying. The outlet of the axial flow pump 1 passes through the connecting pipe 2, and after converging in the middle of the connecting pipe 2, the water spray pipe 3 is vertically drawn downward. The end of the water spray pipe 3 is connected to a large detachable nozzle 4. Axial flow pump 1 The pump body centerline and vertical inclination are set, and the included angle and configuration are changed according to different operating conditions and the frame structure of the trencher.

[0021] Each axial flow pump 1 has a base, which can be used to be fixed on the body frame of the trenching machine, so as to ensure the stability of the axial flow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com