Pressure test device and method for prestressed pipe pile through peripheral pipe pile in component force measuring mode

A technology of prestressed pipe piles and component force, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., and can solve the problem that the load-bearing frame is easy to collapse and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

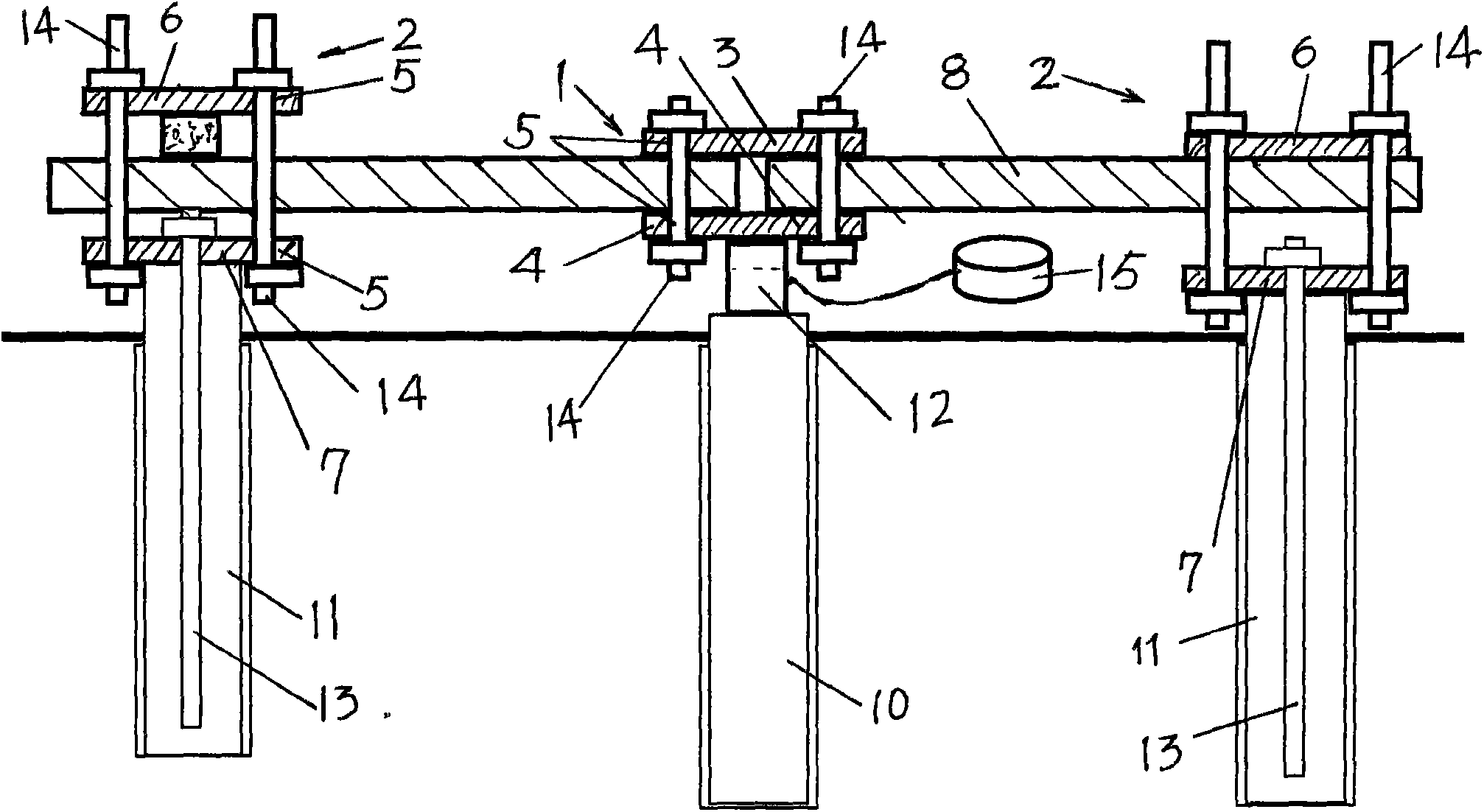

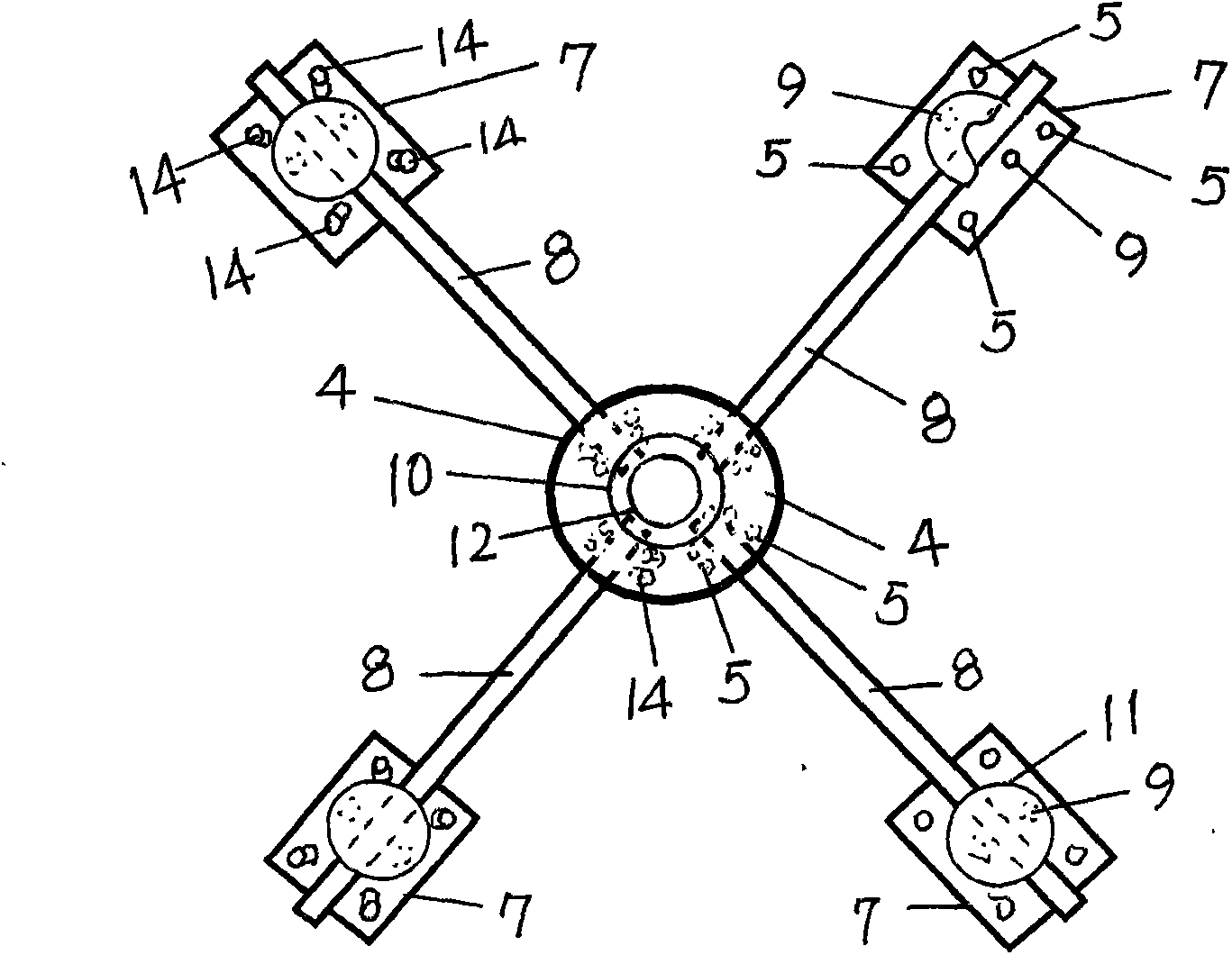

[0052] Embodiment 1, the pressure test device and pressure test method of measuring the prestressed pipe pile with the component force of the surrounding pipe pile in the plane type

[0053] Such as figure 1 , 2 , a pressure test device for measuring prestressed pipe piles with peripheral pipe pile components, including a set of central splints 1 and at least two sets of force splints 2;

[0054] The center splint 1 includes a center upper splint 3 and a center lower splint 4. The center upper splint 3 and the center lower splint 4 are respectively provided with at least two sets of screw holes 5 corresponding to the positions. The screw rods 14 are connected, and different groups of screw rod holes 5 are radially distributed about a central point. Each group of screw rod holes 5 has at least two screw rod holes 5; Steel girder 8 is with I-beam, and fixing a steel girder 8 will wear screw rod hole 5 four, two a row, totally two rows, and two rows are arranged in parallel. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com