Environment-friendly integral pipeline pressing device and pressing method

An integral, environmentally friendly technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the problem of slow re-pressing of pipelines after design changes, shortening of pipeline pressure testing time, high labor intensity, etc. problems, to achieve the effect of reducing pressure test costs, saving pressure labor, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

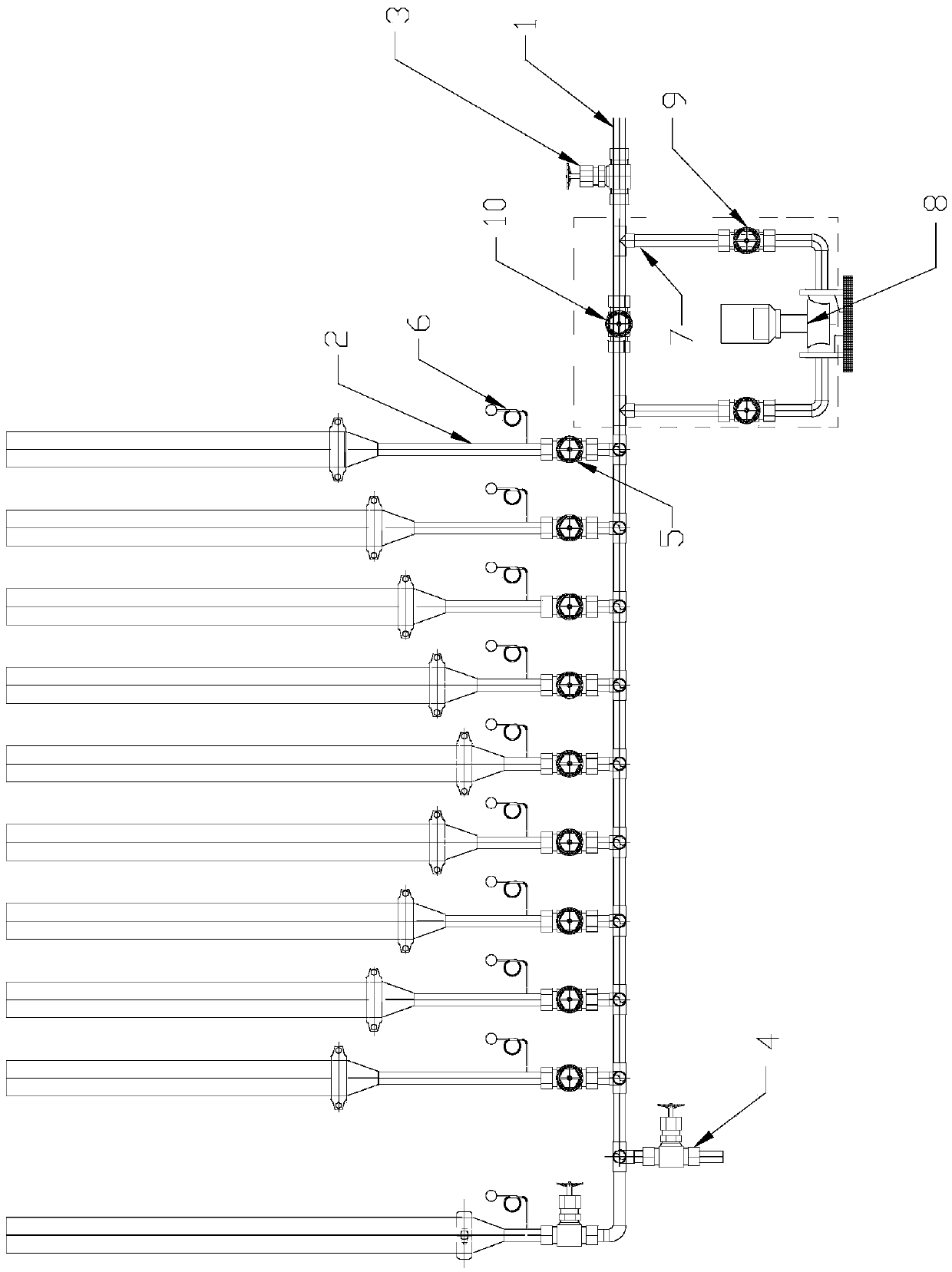

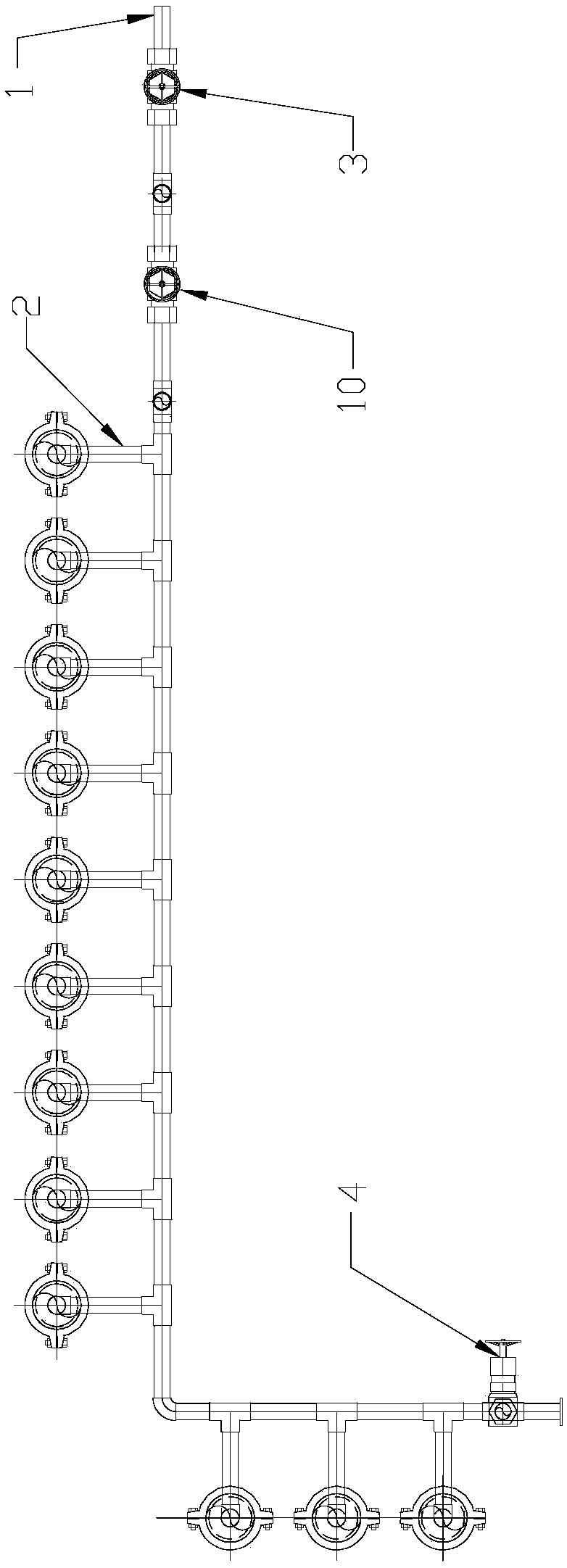

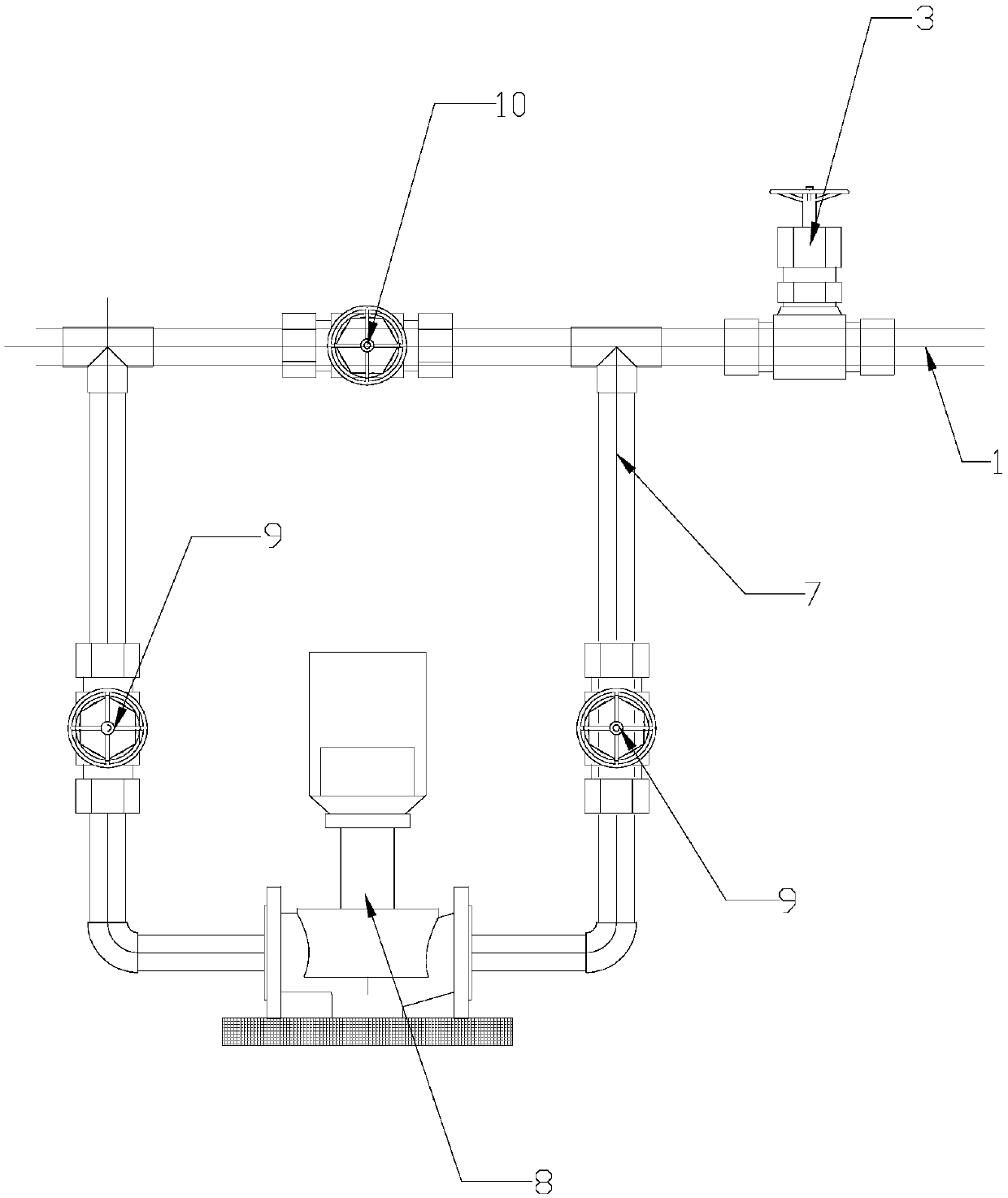

[0017] refer to Figure 1 to Figure 3 , the present invention is an environment-friendly integrated pipeline pressing device, comprising a main pipe 1, on which a plurality of first branch pipes 2 arranged in parallel are arranged, and a main valve 3 is provided at the water inlet end of the main pipe 1, and each The first branch pipe 2 is provided with a branch valve 5 and a pressure gauge 6, and a second branch pipe 7 is arranged in parallel between the main valve 3 and the frontmost first branch pipe 2, and the second branch pipe 7 is provided with a pressure gauge. The pump 8 and the pressure valve 9 located on both sides of the pressure pump 8 and the main pipe 1 between the water inlet end and the water outlet end of the second branch pipe 7 are provided with a water injection valve 10 . Specifically, the water inlet terminal of the main pipe 1 is connected to the water point of the civil works. The parameters of the water point of the civil works are about 0.4 MPa, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com