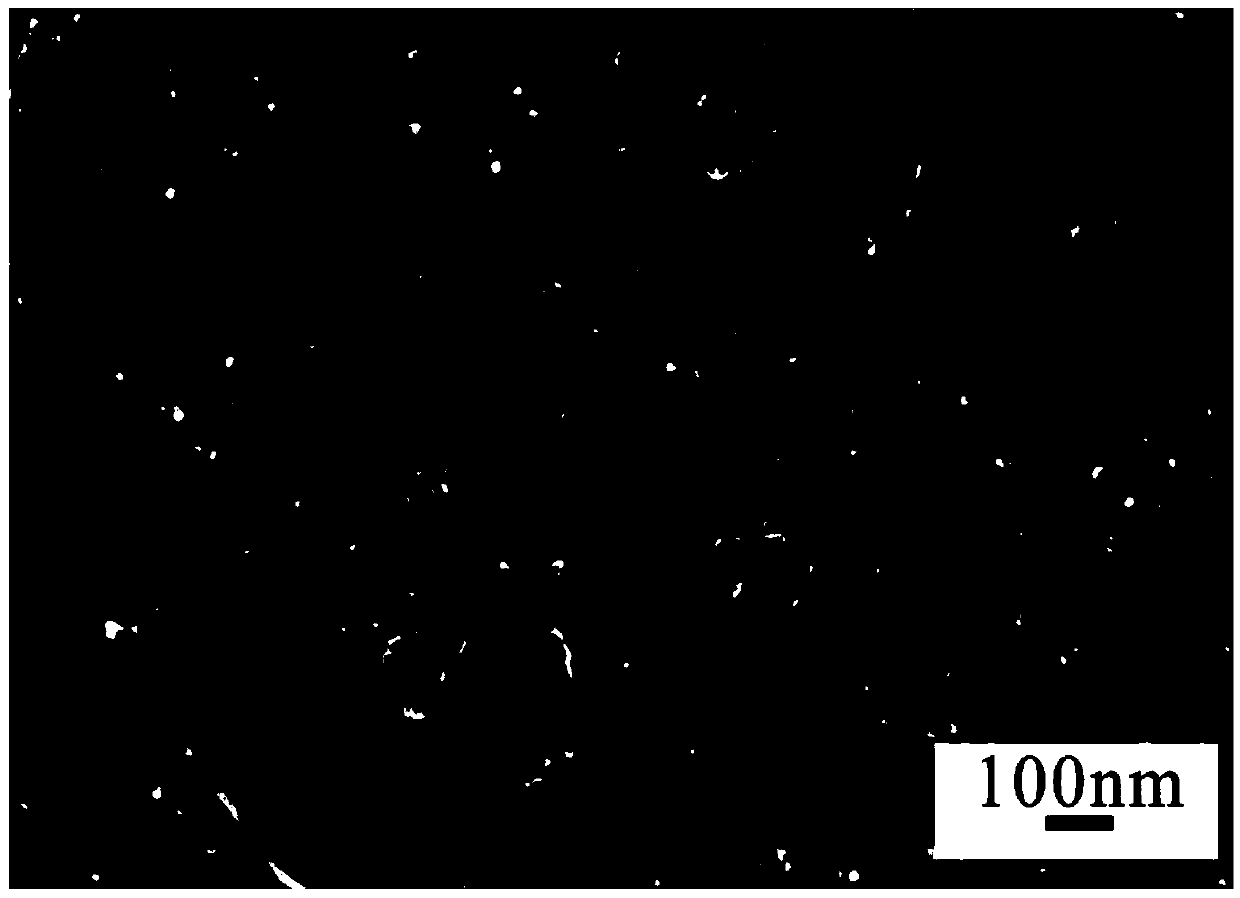

Method for preparing superhydrophobic CNTs/TiO2 hybrid film on base plate

A super-hydrophobic, substrate technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve the effect of simple equipment, low cost, and low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

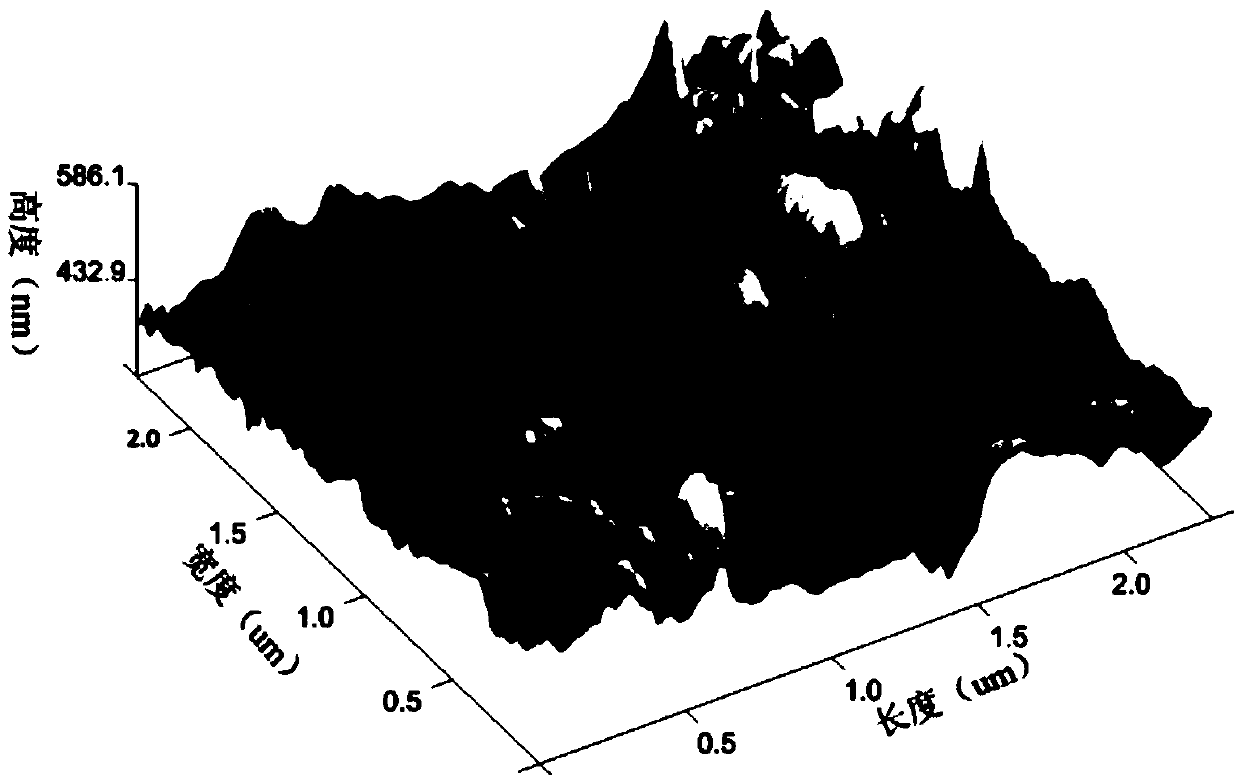

Method used

Image

Examples

Embodiment 1

[0026] Add 0.1mL of cerium oxide polishing solution (concentration: 1%) dropwise on ordinary float glass with length 50mm×width 30mm×height 1mm, polish it back and forth with a sander, and then clean it with deionized water to obtain a polished substrate. piece. Prepare deposition solution, 0.5M (NH 4 ) 2 TiF 6 and 0.5M H 3 BO 3 solution, measure the prepared solution in the container, (NH 4 ) 2 TiF 6 and H 3 BO 3 The dosages are 100mL and 500mL respectively, and then 0.1g of carbon nanotube (10%, aqueous dispersion) solution is added. Immerse the polished substrate vertically in a container containing a mixed deposition solution, place the entire container in a constant temperature water bath, deposit at 25°C for 48 hours, take out the sample, rinse it with deionized water, and store it at room temperature Naturally air-dried to obtain a sample with a good surface deposition. Spin-coat 0.1 mL of fluorosilane solution on the deposited glass surface. The modified su...

Embodiment 2

[0028]Add 10mL cerium oxide polishing solution (concentration 50%) dropwise on ordinary float glass with length 50mm×width 30mm×height 1mm, polish back and forth with a sander, and then clean it with deionized water to obtain a polished substrate . Preparation of deposition solution, 0.005M (NH 4 ) 2 TiF 6 and 0.015M H 3 BO 3 The mixed solution, measure the prepared solution in the container, (NH 4 ) 2 TiF 6 and H 3 BO 3 The dosages are 50mL and 50mL respectively, and then 10g of carbon nanotube (1%, aqueous dispersion) solution is added. Immerse the polished substrate vertically in a container containing a mixed deposition solution, place the entire container in a constant temperature water bath, deposit at 100°C for 3 hours, take out the sample, rinse it with deionized water, and leave it at room temperature Naturally air-dried to obtain a sample with a good surface deposition. Spin-coat 10 mL of fluorosilane solution on the deposited glass surface. The modified ...

Embodiment 3

[0030] Add 0.5mL cerium oxide polishing solution (concentration 25%) dropwise on ordinary float glass with length 50mm×width 30mm×height 1mm, polish it back and forth with a sander, and then clean it with deionized water to obtain a polished substrate. piece. Prepare deposition solution, 0.05M (NH 4 ) 2 TiF 6 and 0.25M H 3 BO 3 The mixed solution, measure the prepared solution in the container, (NH 4 ) 2 TiF 6 and H 3 BO 3 The dosages were 100 mL and 20 mL respectively, and then 5 g of carbon nanotube (5%, aqueous dispersion) solution was added. The substrate whose surface has been polished is vertically immersed in a container containing a mixed deposition solution, and the entire container is placed in a constant temperature water bath, and deposited at 50°C for 20h. Finally, the sample was taken out, rinsed with deionized water, and dried naturally at room temperature to obtain a sample with good surface deposition. Spin-coat 5 mL of fluorosilane solution on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com