A kind of method of preparing aluminum benzoate from calcium-free chromium slag

A calcium-free chromium slag, aluminum benzoate technology, applied in chemical instruments and methods, process efficiency improvement, compounds containing periodic table Group 3/13 elements, etc. Actively and other issues, to achieve high utilization value, realize energy saving and consumption reduction, increase the effect of material recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

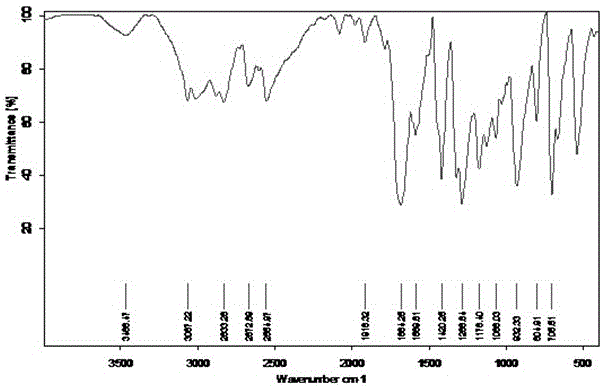

Image

Examples

Embodiment Construction

[0019] The following are specific examples of the present invention, and further describe the technical solution of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0020] 1. Crush 100Kg of calcium-free chromium slag (provided by Hubei Zhenhua Chemical Co., Ltd.) to 320 mesh.

[0021] 2. Soak in 300Kg water for the first time, stir for 2 hours, and filter; soak in 200Kg water for the second time, stir for 2 hours, filter, and combine the second soaking solution.

[0022] 3. Heat the alkaline soaking solution in the previous step to 60-70°C, add the newly prepared sodium sulfide solution with a concentration of 30% (mass percentage), and reduce hexavalent chromium to trivalent chromium precipitation until no precipitation occurs, 30 The consumption of % sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com