A kind of polypropylene composite material automobile water tank beam and preparation method

A composite material and automobile water tank technology, applied in the field of composite materials, can solve problems such as the large weight of automobile water tank beams, and achieve the effects of improving economic adaptability, being beneficial to light weight, and having excellent impact resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An embodiment of the present invention provides a fiber-reinforced polypropylene composite automobile water tank beam, which comprises the following components in mass fractions: 40%-80% of polypropylene, 0%-30% of Toughener, 5%-60% fiber reinforcement, 0.3%-0.5% antioxidant, 0%-1% masterbatch and 0.5%-3% compatibilizer.

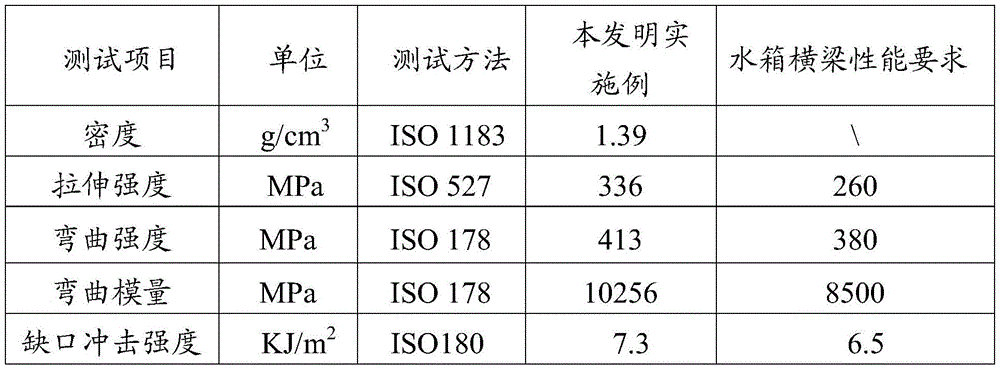

[0030] The polypropylene composite automobile radiator beam provided by the embodiment of the present invention adopts 40%-80% polypropylene, 0%-30% toughening agent, 5%-58% fiber reinforcement, 0.3%-0.5% Antioxidant, 0%-1% masterbatch and 0.5%-3% compatibilizer, and prepared by injection molding process, the density of the water tank beam prepared by the polypropylene composite material is smaller, obviously The weight of the water tank beam is reduced, which is conducive to the lightweight development of the body, thereby improving fuel economy, while its stiffness and impact resistance are better, meeting the technical indicators of the water tank ...

Embodiment 2

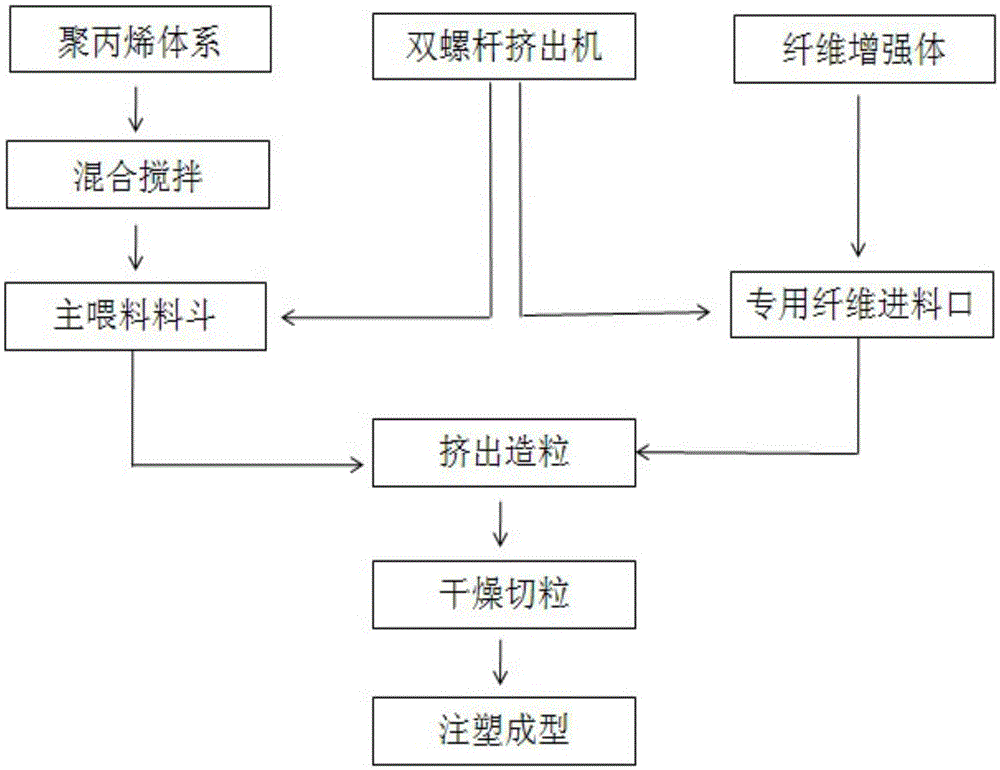

[0043] as attached figure 1 As shown, the embodiment of the present invention provides a method for preparing a fiber-reinforced polypropylene composite automobile radiator beam, which specifically includes the following steps:

[0044] Step 1: Mix polypropylene, toughener, antioxidant, color masterbatch and compatibilizer under a high-speed mixer for 5-20 minutes;

[0045]Step 2: Add the mixed material obtained in Step 1 into the main feeding hopper of the twin-screw extruder, and add the fiber reinforcement into the special fiber feed port of the twin-screw extruder, and extrude through the twin-screw extruder Extrude and pelletize, dry and pelletize to obtain fiber-reinforced polypropylene composite pellets;

[0046] Step 3: Injection molding the fiber-reinforced polypropylene composite material particles in step 2 through an injection molding machine to obtain a fiber-reinforced polypropylene composite material automobile water tank beam;

[0047] The mass fractions of t...

Embodiment 3

[0063] Embodiments of the present invention provide a fiber-reinforced polypropylene composite automobile water tank beam and a preparation method thereof. The preparation method specifically includes the following steps:

[0064] Step 1: Weigh 40% homopolypropylene, 10% ethylene-propylene-octene terpolymer, 0.3% antioxidant 1010 and antioxidant 168 compound, 0.1% Color masterbatch and 3% maleic anhydride, and mix and stir for 5-20min under a high-speed mixer;

[0065] Step 2: Add the mixed material in step 1 into the main feeding hopper of the twin-screw extruder. At the same time, add carbon fibers with a mass fraction of 46% into the special fiber feed port of the twin-screw extruder, and pass The twin-screw extruder is extruded and granulated, and dried and cut into pellets. During this process, the temperature of each temperature zone of the twin-screw extruder is set as: 160°C for the first zone, 165°C for the second zone, 170°C for the third zone, and 170°C for the four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com