Airflow harrow type sludge dryer

A sludge drying and rake technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of increasing the processing capacity, increasing the power consumption of the dryer, and high operating costs, eliminating the possibility of deflagration and increasing pollution. The effect of reducing mud drop height and running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

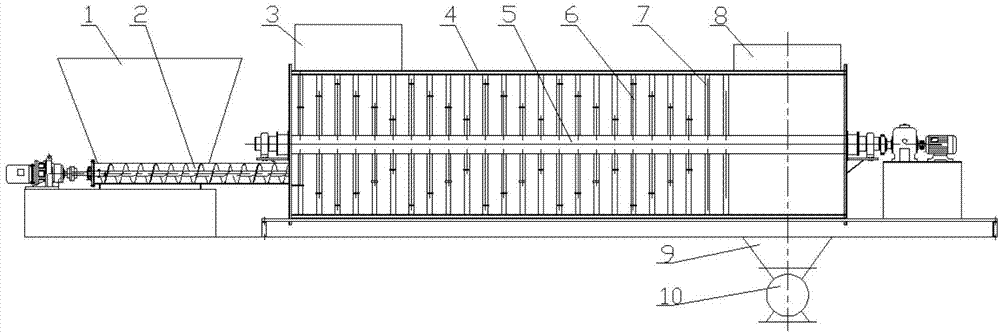

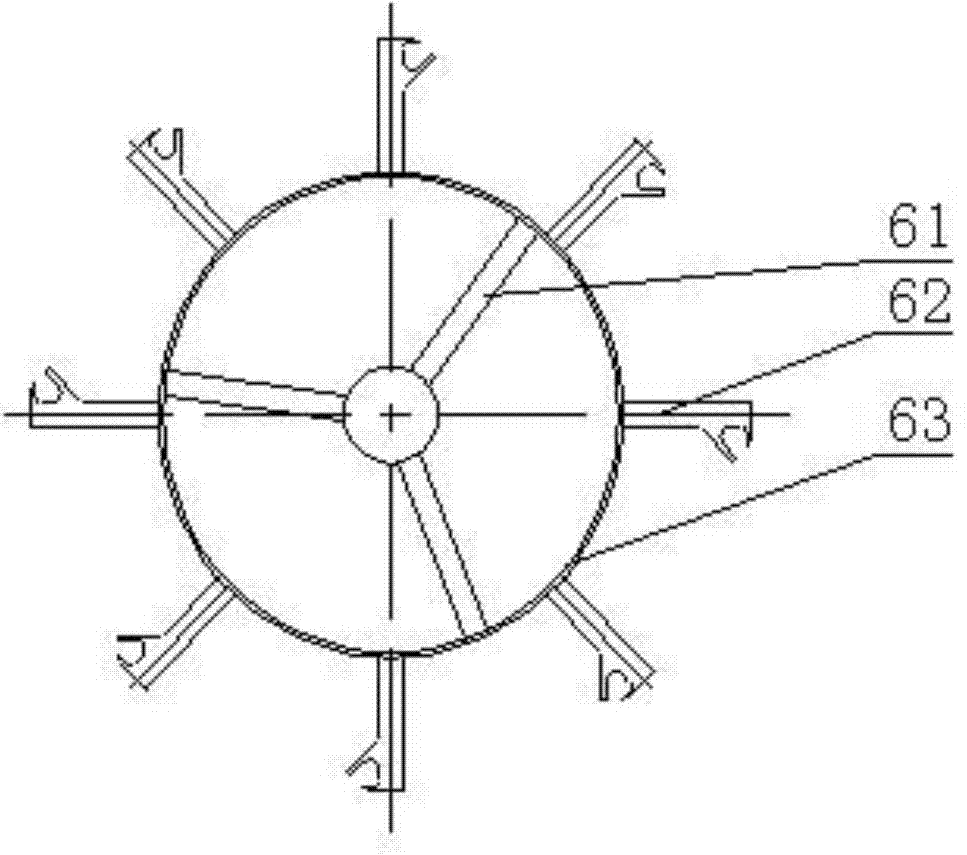

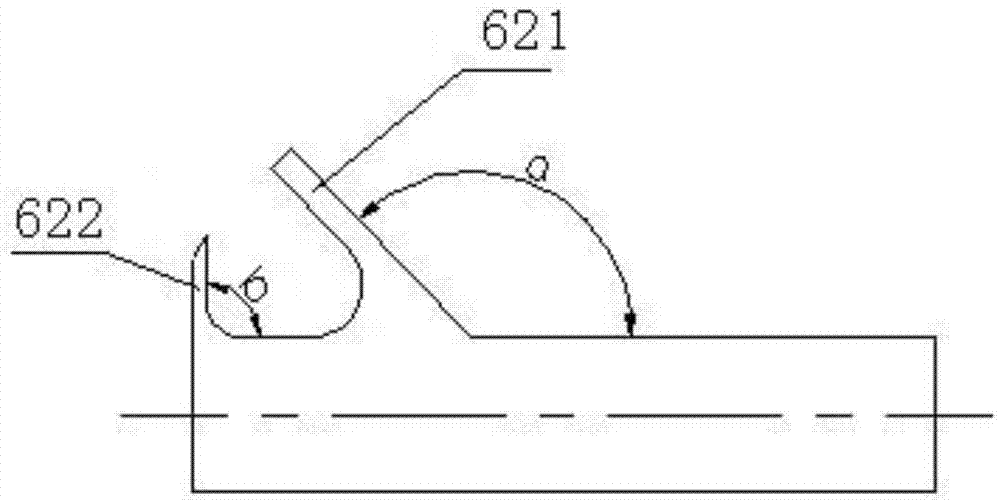

[0021] as attached figure 1 and 4 As shown, the airflow rake sludge dryer includes a circular cylindrical shell 4 with a fixed position, and a rotating shaft 5 coaxial with the shell 4 is installed in the center of the shell 4, and the rotating shaft 5 can be driven by the power device Rotate down, at least one set of incremental stirring blades, several sets of decreasing stirring blades and straight stirring blades 7 are fixedly installed on the rotating shaft 5, and the incremental stirring blades are arranged on the housing 4 On the front side of the housing 4, the set of descending stirring blades is arranged in the middle of the housing 4, and the straight stirring blades 7 are arranged on the rear side of the housing 4. as attached figure 2 As shown, each of the stirring blade groups includes more than two transition ring stirring blades 6, and the transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com