Integrated heterogeneous baffled Fenton continuous reactor

A technology of baffles and reactors, applied in the field of integrated baffles Fenton strong oxidation treatment device, can solve the problems of cumbersome catalyst preparation methods, poor operability and economy, increased investment and operating costs, and achieve Improve the treatment effect and the efficiency of chemical use, reduce the amount of less iron-containing sludge produced, and reduce the effect of chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

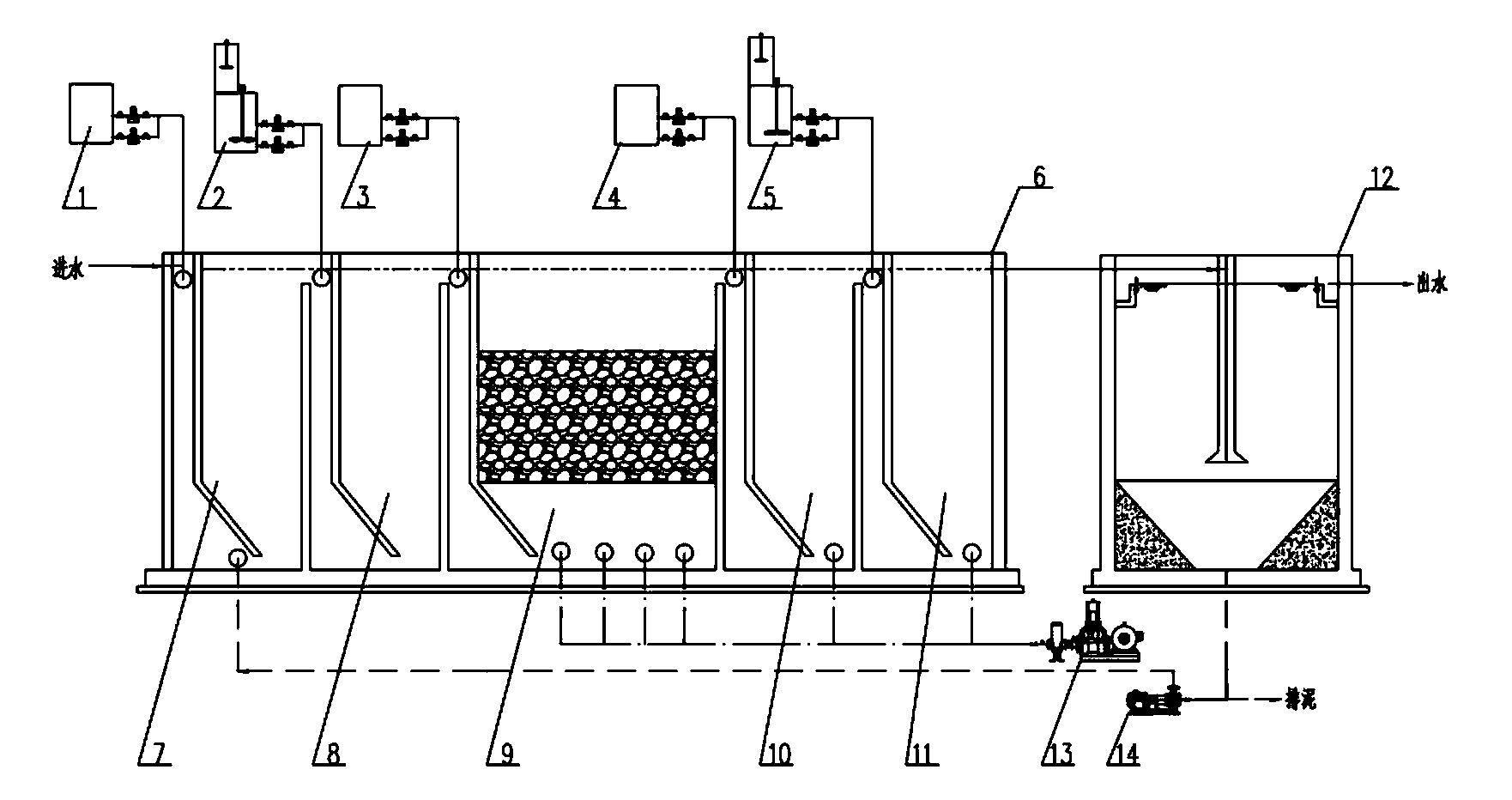

[0037] The integrated baffle plate Fenton continuous reactor device is used to treat the biochemically treated effluent of a pulp and papermaking wastewater with a COD of 190mg / L. The device includes the following process steps:

[0038] 1. The wastewater to be treated after biochemical treatment of pulping and papermaking is pumped into the acid adding tank with a pump. Turn on the acid adding device 1, add sulfuric acid to the front end of the acid adding pool 7, adjust the pH to about 3.0, use the ferrous adding device 2 to add ferrous sulfate 60 mg / L to the ferrous adding pool 8, and enter the Fenton main reaction pool 9 end, through the H 2 o 2 Dosing device 3 adds 300mg / L H 2 o 2 , and reacted in Fenton main reaction tank 9 for 30 minutes. After the reaction is complete, it enters the alkali-adding tank 10, and uses the alkali-adding device 4 to add NaOH to adjust the pH to 9.0. After adding PAM to the front section of the PAM-adding tank 11 for flocculation, it flow...

Embodiment 2

[0043] The integrated baffle plate Fenton continuous reactor device is used to treat the biochemically treated effluent of a certain chemical wastewater with a COD of 520mg / L. The device includes the following process steps:

[0044] 1. The chemical wastewater to be treated is pumped into the acid adding pool after biochemical treatment. Turn on the acid adding device 1, add sulfuric acid to the front end of the acid adding pool 7, adjust the pH to about 3.0, use the ferrous adding device 2 to add ferrous sulfate 150 mg / L to the ferrous adding pool 8, and enter the Fenton main reaction pool 9 end, through the H 2 o 2 Dosing device 3 adds 850mg / LH 2 o 2 , and reacted in Fenton main reaction tank 9 for 45 minutes. After the reaction is complete, it enters the alkali-adding tank 10, and uses the alkali-adding device 4 to add NaOH to adjust the pH to 9.0. After adding PAM to the front section of the PAM-adding tank 11 for flocculation, it flows into the sedimentation tank 12. ...

Embodiment 3

[0049] The integrated baffle plate Fenton continuous reactor device is used to treat the biochemically treated effluent of a palm oil factory with a COD of 950mg / L. The device includes the following process steps:

[0050] 1. The remaining sludge to be treated is pumped into the acid adding tank with a pump. Turn on the acid adding device 1, add sulfuric acid to the front end of the acid adding pool 7, adjust the pH to about 3.0, use the ferrous adding device 2 to add ferrous sulfate 250mg / L to the ferrous adding pool 8, and enter it at the entrance of the Fenton main reaction pool 9 end, through the H 2 o 2 Dosing device 3 adds 2125mg / LH 2 o 2 , and reacted in Fenton main reaction tank 9 for 60 minutes. After the reaction is complete, it enters the alkali-adding tank 10, and uses the alkali-adding device 4 to add NaOH to adjust the pH to 9.0. After adding PAM to the front section of the PAM-adding tank 11 for flocculation, it flows into the sedimentation tank 12.

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com