Special fiber mortar stirrer and its use method

A fiber mortar and mixer technology, applied in cement mixing devices, chemical instruments and methods, control devices, etc., can solve problems such as expensive, difficult to meet the construction requirements of domestic PVA high-performance cement-based composite materials, and strain hardening cannot occur. To achieve the effect of uniform distribution of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

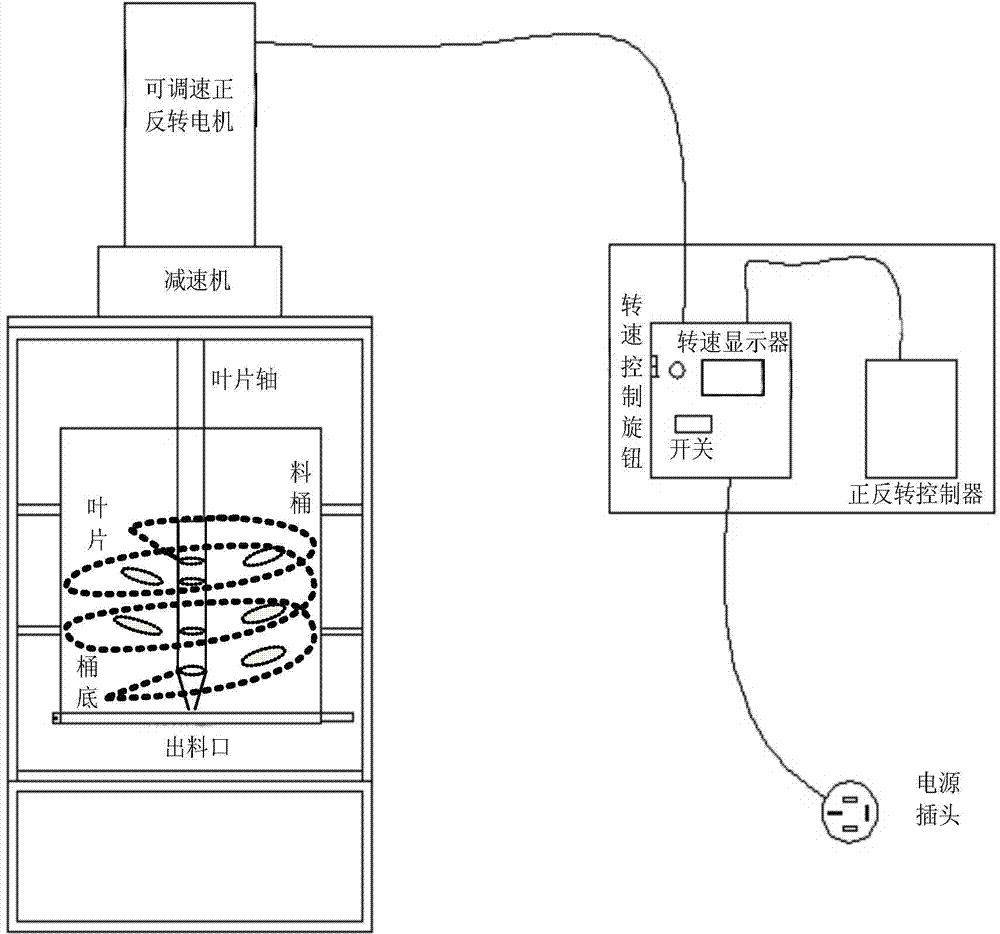

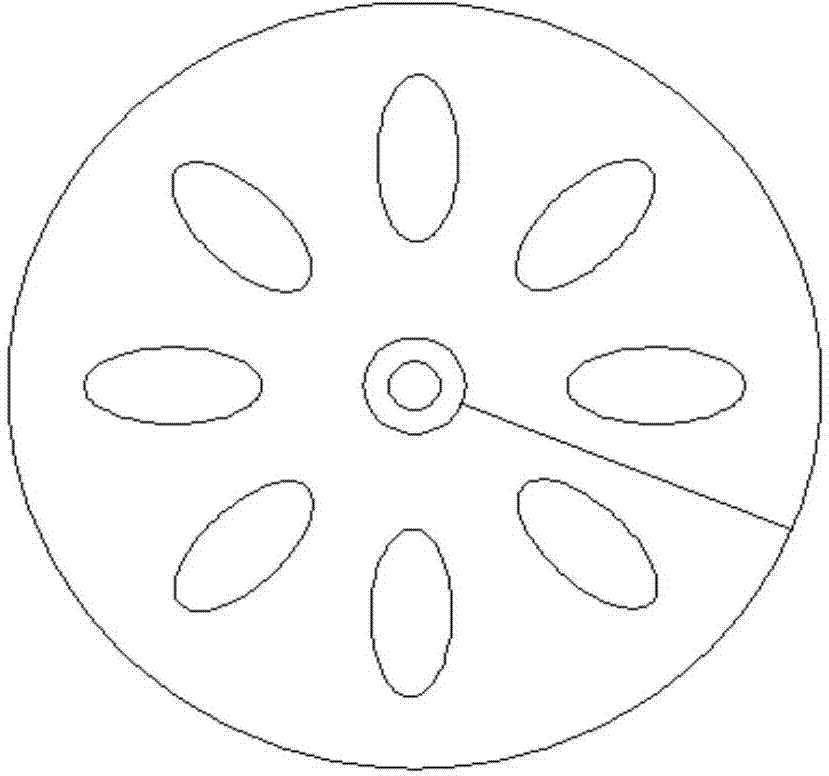

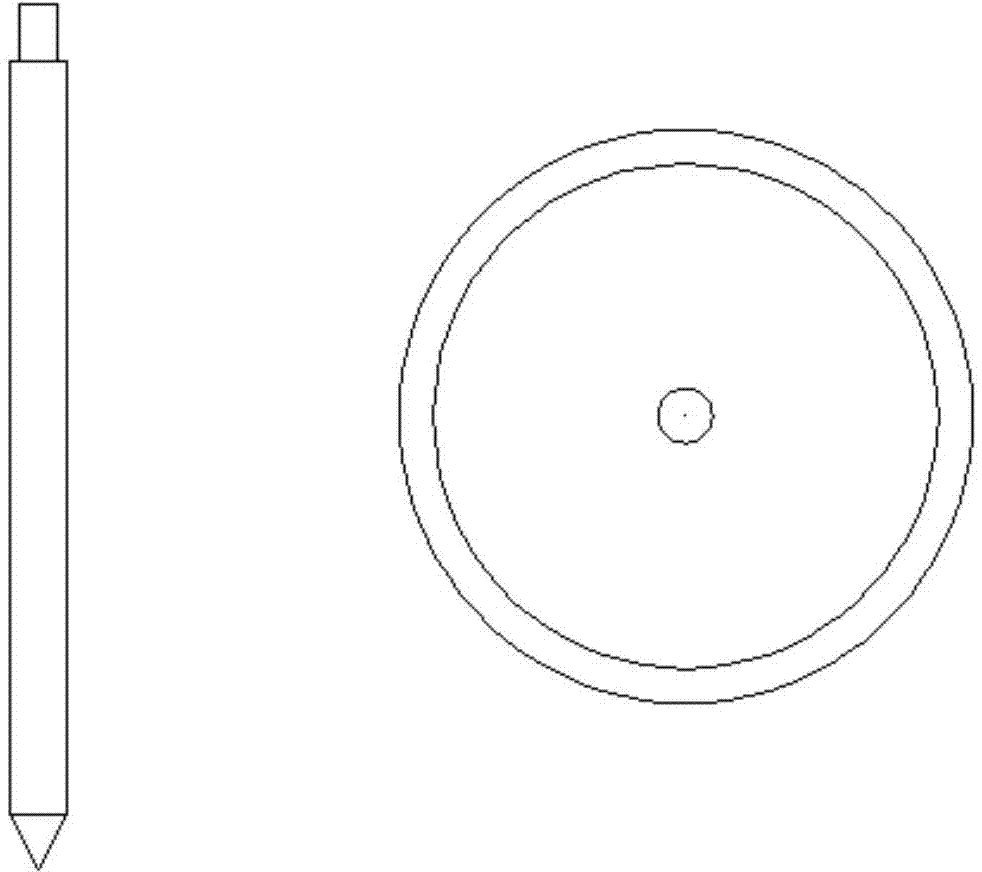

[0017] Such as Figure 1~3 As shown, the special mixer for fiber mortar includes a motor, a reducer, a bucket, a blade, and a blade shaft; the motor adopts a positive and negative rotation mode during operation, and the reduction ratio of the reducer is 3.5:1 to increase the torque of the mixing blade. The blades are connected as a whole around the blade shaft and are in a spiral shape, and regular and alternate elliptical holes are distributed on the blades; the motor, reducer, bucket, and blade shaft are connected vertically, and the upper end of the blade shaft is covered with a flange and connected to the reducer. The lower end of the blade shaft is a vertebral body structure, with the vertebral tip facing downward.

[0018] The control part of the forward and reverse motor includes a power switch, a speed control knob, a speed displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com