Bamboo veneer integrated panel and production technological method thereof

A technology of veneer and bamboo chips, which is applied in the direction of wood processing equipment, jointing of wooden veneers, chemical instruments and methods, etc., can solve the problems of low production efficiency, fragility, and small format of bamboo veneer, and achieve reduction Small processing difficulty, improved bonding performance, and the effect of continuous mechanical processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail.

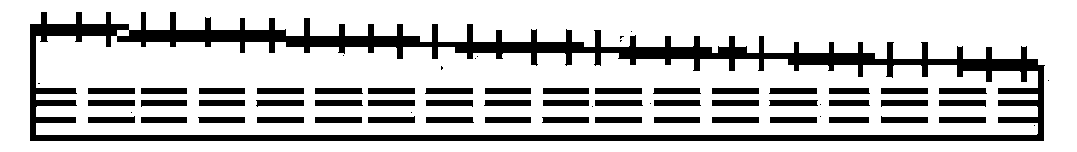

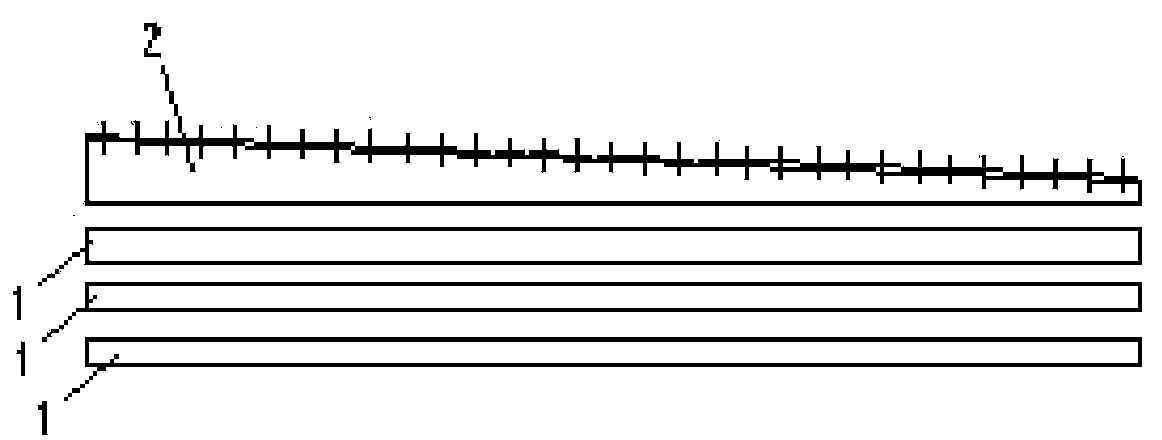

[0036] see figure 1 , is a schematic diagram of a planar wedge-shaped bamboo slice after leveling the arc-shaped bamboo slices, from figure 1 It can be seen from the figure that one end of the bamboo slice is narrow and thin, and the other end is wide and thick. see figure 2 , image 3 ,Will figure 1 Remove the bamboo green layer of the bamboo slices shown, roll the bamboo yellow layer, and layer the bamboo slices to obtain three layers of bamboo meat type bamboo slices 1 with equal thickness and non-equal width and a layer of bamboo with non-equal thickness and non-equal width. Yellow wedge-shaped bamboo slices 2. see Figure 4 , Figure 5 Place the bamboo meat type bamboo slices 1 horizontally, the same end of the two adjacent bamboo slices is that the wide end and the narrow end are handed over closely and neatly arranged, and the longitudinal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com