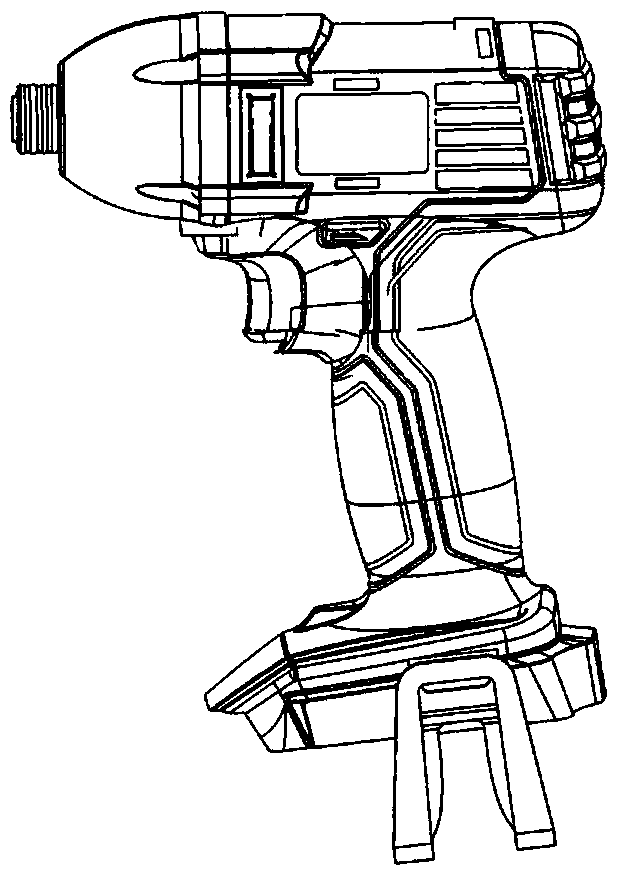

Electric spanner

A wrench and time technology, applied in the field of electric wrenches, can solve the problems of non-adjustable striking force and irreducible striking force of striking screws, and achieve the effects of adjustable striking time, stable and solid parts, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

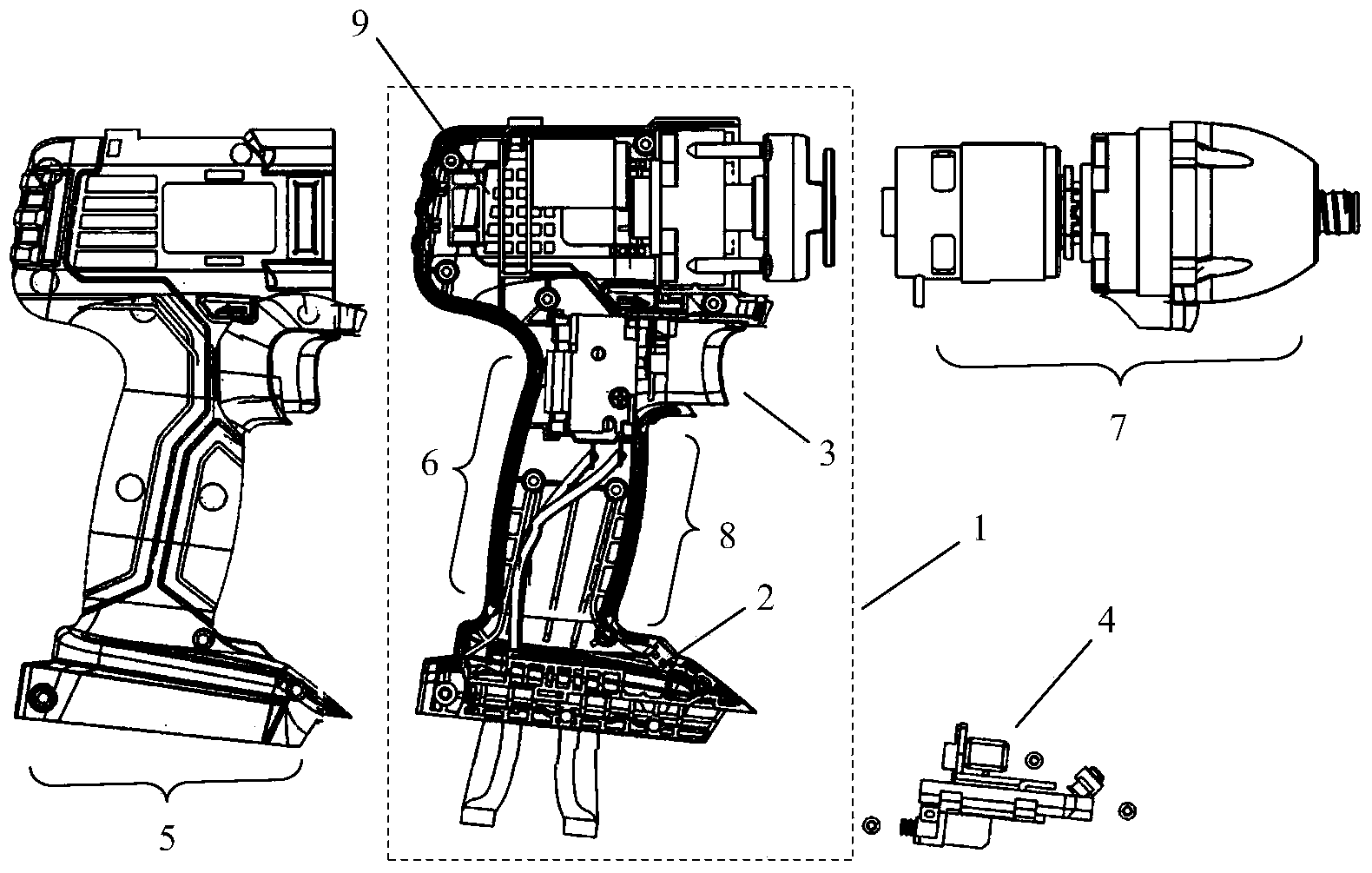

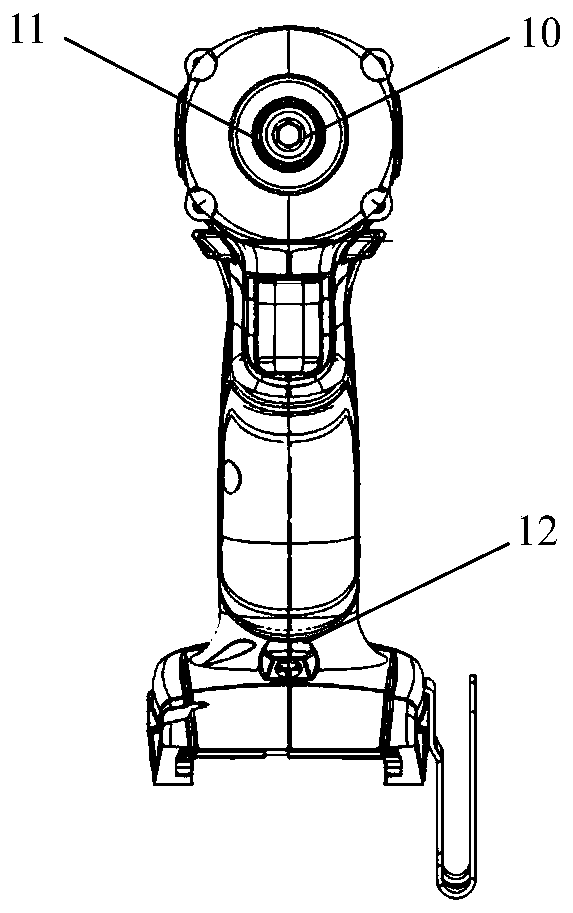

[0046] An electric wrench, comprising a single-chip microcomputer device 2, a switch 3, a power supply device 4, a rear part 5, a machine column 6, a front part 7, a handshake device 8, a motor 9, a wrench shaft 10, a flyweight body 11 and a time setting module 12. The front part 7 and the rear part 5 form the casing part of the motor, and the casing part of the motor, the main body 1 and the power supply device 4 together form an electric wrench, wherein the front part 7 is connected with the machine column 6, and the machine A switch 3 is connected to the front end of the junction between the front part 7 and the machine column 6 , and a handshake device 8 is connected to the lower rear end of the machine column 6 . On main body 1, be provided with single-chip microcomputer device, this single-chip microcomputer device comprises a single-chip microcomputer equipment 2 and time setting module 12, single-chip microcomputer equipment 2 is positioned between power supply unit 4 a...

Embodiment 2

[0048] An electric wrench, which consists of a main body 1 (comprising a single-chip microcomputer device 2, a switch 3, a machine column 6, a handshake device 8 and a motor 9), a power supply device 4, a rear part 5, a front part 7, a wrench shaft 10, a flying The hammer body 11 and the time setting module 12, the front part 7 and the rear part 5 form the casing part of the motor, and the casing part of the motor, the main body 1 and the power supply unit 4 form an electric wrench together, wherein the front part 7 Connected with the machine column 6, the front end of the junction between the front part 7 and the machine column 6 is connected with a switch 3, and the lower rear end of the machine column 6 is connected with a handshake device 8; the trigger shaft 10 is adjacent to the flyweight body 11 and is located at within the casing. On main body 1, be provided with single-chip microcomputer device, this single-chip microcomputer device comprises a single-chip microcomput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com