Finish forging die for forging aluminum alloy wheel

A technology of aluminum alloy and wheels, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of poor mechanical properties, difficult demoulding, workpiece damage, etc., so as to solve the problem of uneven iron material and guarantee Mechanical properties, the effect of facilitating wear parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

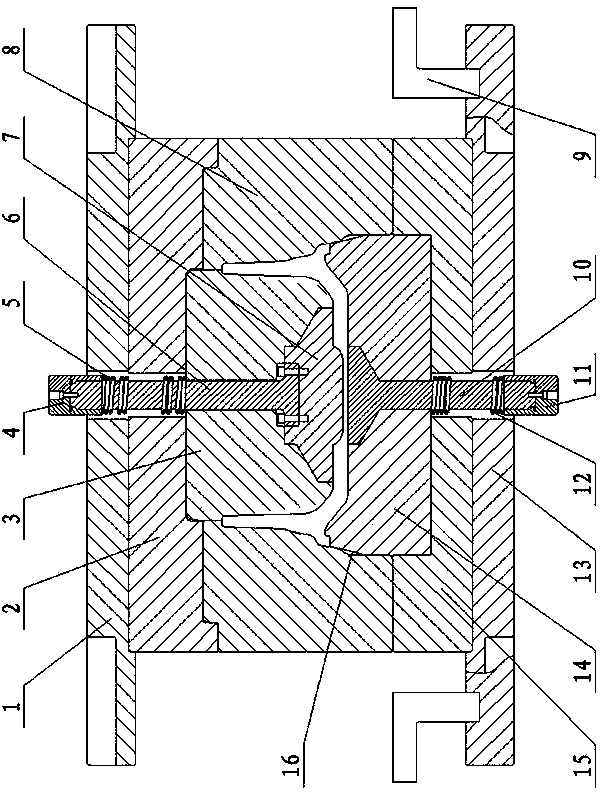

[0010] A final forging die for forging aluminum alloy wheels, comprising an upper template 1 and a lower template 13, a lower mold 14 is fixed above the lower template 13 through a lower supporting plate 15, and an upper mold is fixed below the upper template 1 through an upper supporting plate 2 Die, the upper mold includes an upper mold core 3 facing the lower mold 14, the upper mold core 3 is covered with an upper mold cover 8 fixedly connected with the upper supporting plate 2, and the lower part of the upper mold cover 8 is sleeved outside the lower mold 14 , the bottom of the upper die cover 8 is provided with a notch protrusion engaged with the lower supporting plate 15, forming a closed forging cavity between the upper die core 3, the upper die cover 8 and the lower die 14; There is a circle of gaps on the outer wall of the upper part, and a flash reserved cavity 16 is formed between the inner wall of the upper mold sleeve and the gap of the lower mold. A lower ejector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com