Flotation method for sulfur and iron in refractory concentrates

A technology of concentrate and flotation, applied in flotation, solid separation, etc., can solve problems such as unstable heat balance in boiling roasting system, ineffective use of iron resources, complex composition of pulp in sulfur separation process, etc., to achieve great practicality and Economic benefits, adhere to energy saving and consumption reduction, and realize the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

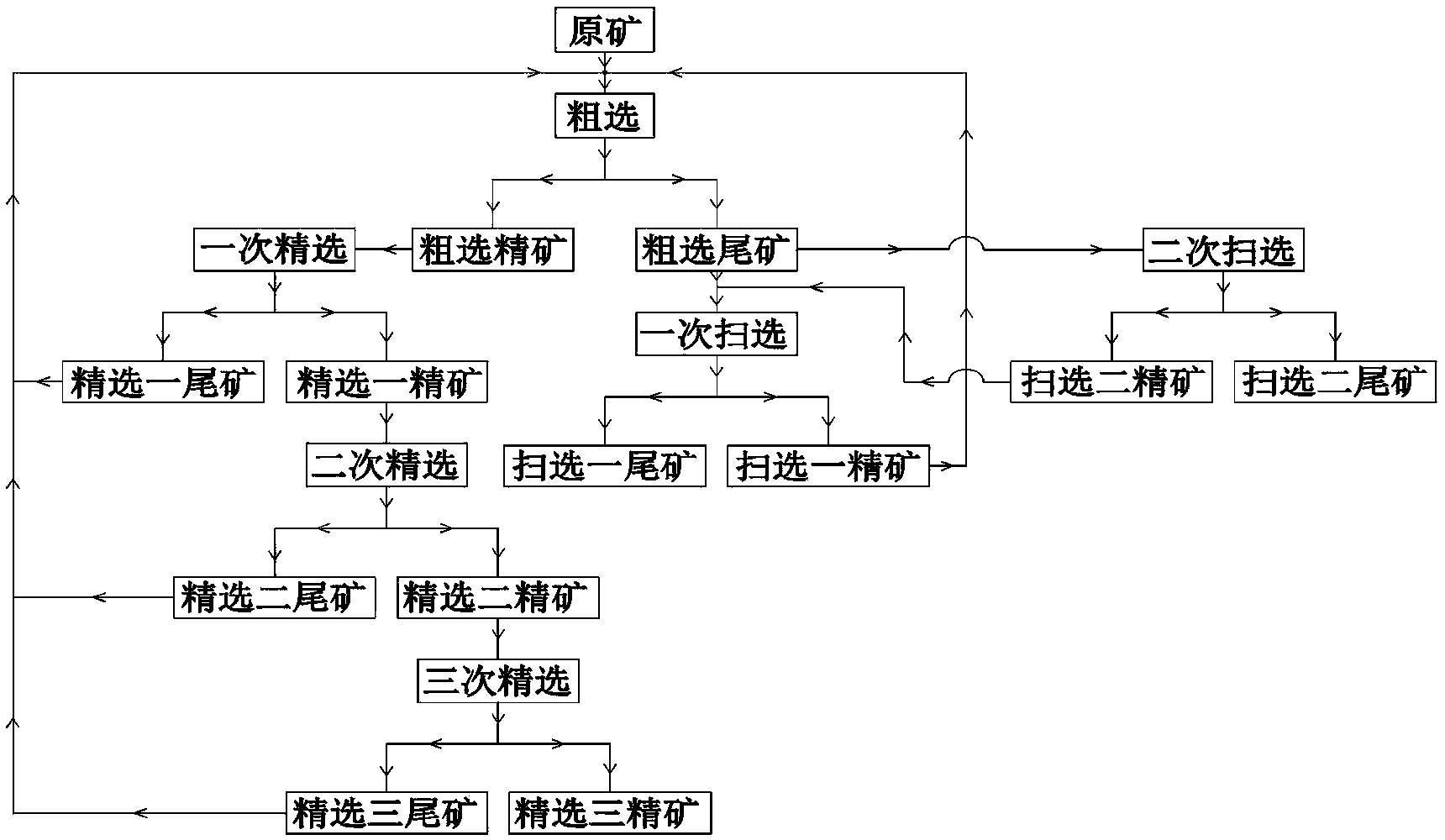

[0037] Such as figure 1 As shown, after taking the ratio of Beijiang, Zhengyuan and Xinyuan mines (9:5:2), the sulfur and iron contents in the ore are 18.66% and 20.67% respectively.

[0038] The chemical composition of sulfur-containing gold concentrate 1 is as follows:

[0039] Table 1. Content of element 1 in sulfur-bearing gold concentrates (%)

[0040] .

[0041] (1) rough selection

[0042] The gold concentrate with a sulfur content of 18.66% is mixed with water to form a 30%-35% slurry into the roughing tank, and sulfuric acid is added to stir for 3 minutes to keep the pH of the slurry at 5; add copper sulfate in sequence to each ton of gold concentrate 300-500 grams, stirred for 2 minutes; 320 grams of mercapto sulfide mineral collectors, stirred for 2 minutes; 60 grams of foaming agent, stirred for 1 minute, the foam in the flotation tank maintained an appropriate thickness, and floated for 6 minutes; The foam product is rougher concentrate, and the product in the...

Embodiment 2

[0058] After taking Zaozigou, Tianhao, Beijiang, Zhengyuan, Xinyuan and Kunhe mines (45:18:18:10:4:18) as the ratio, the sulfur and iron contents in the ore are 14.06% and 14.63% respectively

[0059] The chemical composition of sulfur-containing gold concentrate 2 is as follows:

[0060] Table 3. Element 2 content of sulfur-bearing gold concentrate (%)

[0061] .

[0062] (1) rough selection

[0063] The gold concentrate with a sulfur content of 14.06% is mixed with water to form a 30%-35% pulp into the roughing tank, and sulfuric acid is added to stir for 3 minutes to keep the pH of the pulp at 5; add copper sulfate in sequence to each ton of gold concentrate 300-500 grams, stirred for 2 minutes; 320 grams of mercapto sulfide mineral collectors, stirred for 2 minutes; 60 grams of foaming agent, stirred for 1 minute, the foam in the flotation tank maintained an appropriate thickness, and floated for 6 minutes; The foam product is rougher concentrate, and the product in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com