Three-dimensional graphene/hydroxyapatite hydrogel material

A hydroxyapatite and graphene technology, applied in the field of nanocomposite materials and biological materials, can solve the problems of increased preparation cost, insufficient porosity, complicated regulation process, etc., and achieves good drug release effect, high porosity and convenience. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

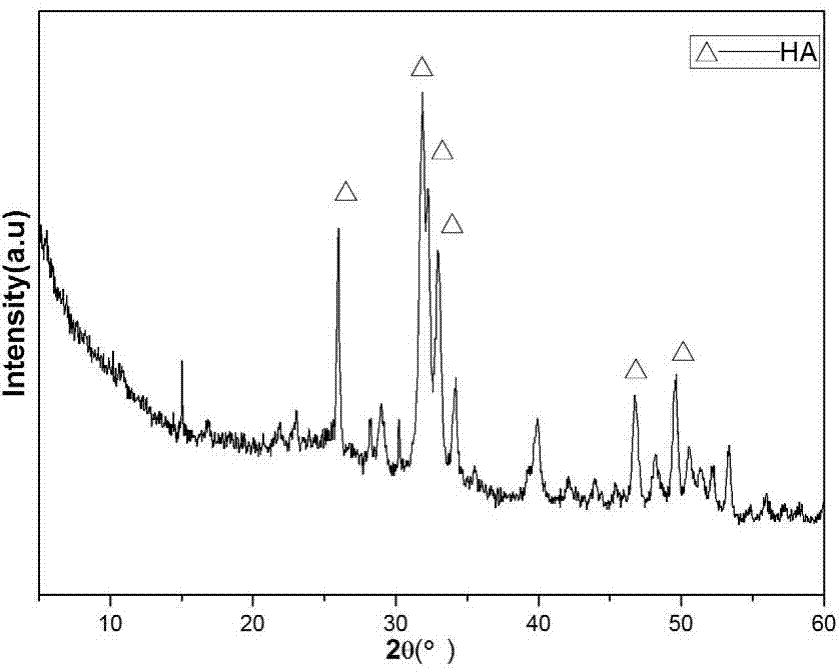

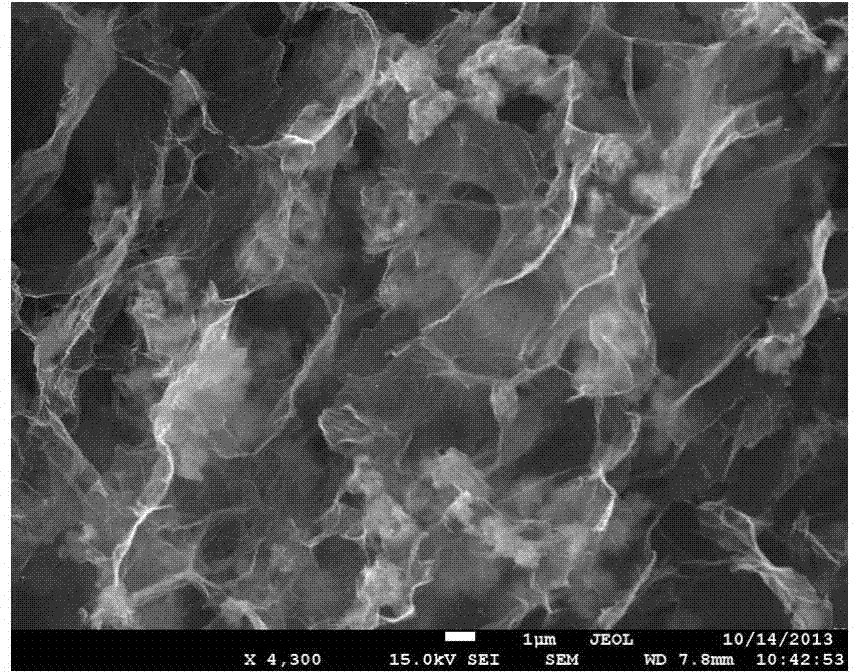

[0027] A three-dimensional graphene / hydroxyapatite hydrogel material, prepared by the following method:

[0028] Mix the graphene oxide solution with a concentration of 6 mg / ml and the hydroxyapatite slurry with a concentration of 50 mg / ml, stir well to obtain a mixed solution, and make the mass ratio of graphene oxide and hydroxyapatite in the mixed solution The ratio is 1:1.7; then the mixed solution is transferred to a hydrothermal reaction kettle, and the reaction is carried out at 160°C for 1 hour, then cooled to room temperature, and the free water on the surface of the product is absorbed by filter paper to obtain a three-dimensional graphene / hydroxyphosphorus Limestone hydrogel material.

[0029] The hydroxyapatite slurry used in this example is synthesized by the co-precipitation method of calcium salt and phosphate with a Ca / P molar ratio of 1.67. Its specific synthesis process is:

[0030] Prepare the calcium salt-calcium nitrate into a 1mol / L solution (calcium ni...

Embodiment 2

[0035] The operation of this example is basically the same as that of Example 1, except that the concentration of the hydroxyapatite slurry is 55 mg / ml, the concentration of the graphene oxide solution is 7.5 mg / ml, the concentration of graphene oxide and hydroxyapatite The holding time of the mixed solution in the hydrothermal reactor is 24 hours, and the holding temperature is 180° C.; when synthesizing the hydroxyapatite slurry, the calcium salt is calcium chloride, and the phosphate is dipotassium hydrogen phosphate.

Embodiment 3

[0037] The operation of this example is basically the same as that of Example 1, except that the concentration of the hydroxyapatite slurry is 180 mg / ml, the concentration of the graphene oxide solution is 10 mg / ml, and the mixing of graphene oxide and hydroxyapatite The holding time of the solution in the hydrothermal reaction kettle is 10 hours, and the holding temperature is 170°C; when synthesizing the hydroxyapatite slurry, the calcium salt is calcium acetate, and the phosphate is sodium pyrophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com