Method for preparing acid-resisting trans-fatty acid-free creamer

A technology of non-dairy creamer and fatty acid, which is applied in the field of acid-resistant zero-trans fatty acid non-dairy creamer and its preparation, which can solve the problems of limiting the application of non-dairy creamer, achieve the effects of improving taste and taste, reducing safety risks, and expanding the scope of application

Inactive Publication Date: 2014-04-30

JIANGNAN UNIV

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Most of the embedding emulsifiers used in traditional non-dairy creamer are sodium caseinate, because sodium caseinate is easy to flocculate and precipitate in an acidic environment, which makes the emulsion break and demulsify, which limits the application of non-dairy creamer in acidic food

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] Example 2

Embodiment 2

[0031] Example 3

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

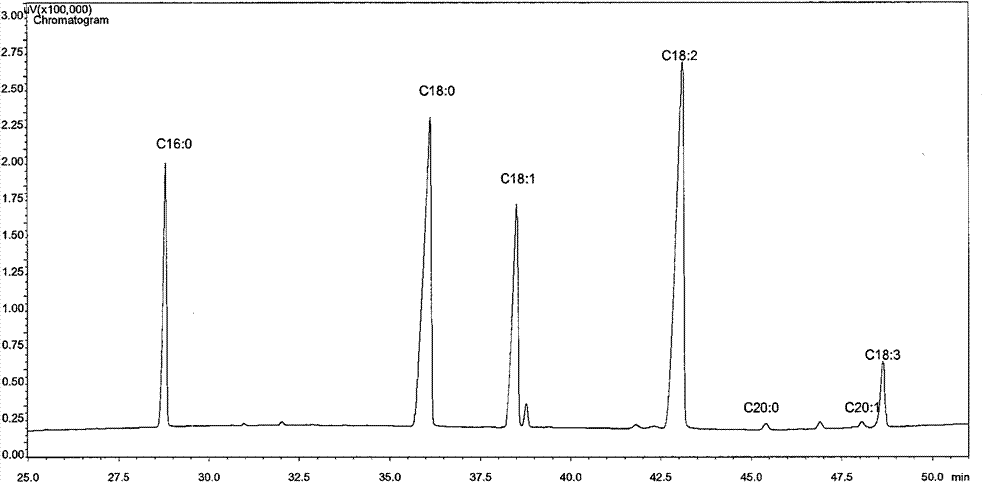

A method for preparing an acid-resisting trans-fatty acid-free creamer belongs to the field of food processing technology. Soybean oil and extremely hydrogenated soybean oil are subjected to enzymatic transesterification of soybean oil by using immobilized lipase, wherein the weight ratio of soybean oil to extremely hydrogenated soybean oil is 30:70, 40:60, 50:50, 60:40, 70:30. The product of transesterification is used as the main source of oil for preparation of the creamer. The creamer mainly comprises the following components by weight: 20-50% of the oil from transesterification, 10-20% of starch octenylsuccinate, 0.01-0.1% of an essence, 0.01-0.1% of a pigment and the balance of glucose syrup. The above components are subjected to heating dissolution, shear mixing, high pressure homogenization and spray drying to obtain the acid-resisting trans-fatty acid-free creamer. The invention reduces the content of trans-fatty acid in the creamer to zero, at the same time greatly reduces the usage of food additives, and reduces the safety risk of the product. In addition, the creamer product can keep stable in an acidic environment, and can be added to an acidic drink as an ingredient, so as to expand the scope of application of the creamer.

Description

technical field [0001] The invention belongs to the technical field of food processing, and in particular relates to an acid-resistant zero-trans fatty acid non-dairy creamer and a preparation method thereof. Background technique [0002] Non-dairy creamer, also known as creamer, is made of hydrogenated vegetable oil as the main raw material, supplemented with maltose syrup or maltodextrin, adding emulsifiers, thickeners, stabilizers, flavors, pigments and other raw materials and food additives after emulsification, homogenization, The powder product processed by spray drying and other processes is a kind of microencapsulated powder oil. Adding it to food or beverage can produce a cream-like flavor, which can partially or completely replace milk powder. Now non-dairy creamer is widely used in baked food, cold food, pasta food, candy, solid beverage and other fields. [0003] Traditional non-dairy creamer uses hydrogenated vegetable oil between 20-80% according to its fat c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23D9/04

Inventor 刘杰王彪刘津张根义

Owner JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com