Hydraulic seal assembly for a thermoplastic material dispensing valve assembly

A thermoplastic material, hydraulic sealing technology, applied in the direction of engine sealing, engine components, devices for coating liquid on the surface, etc., can solve problems such as erosion of sealing mechanism and failure of sealing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

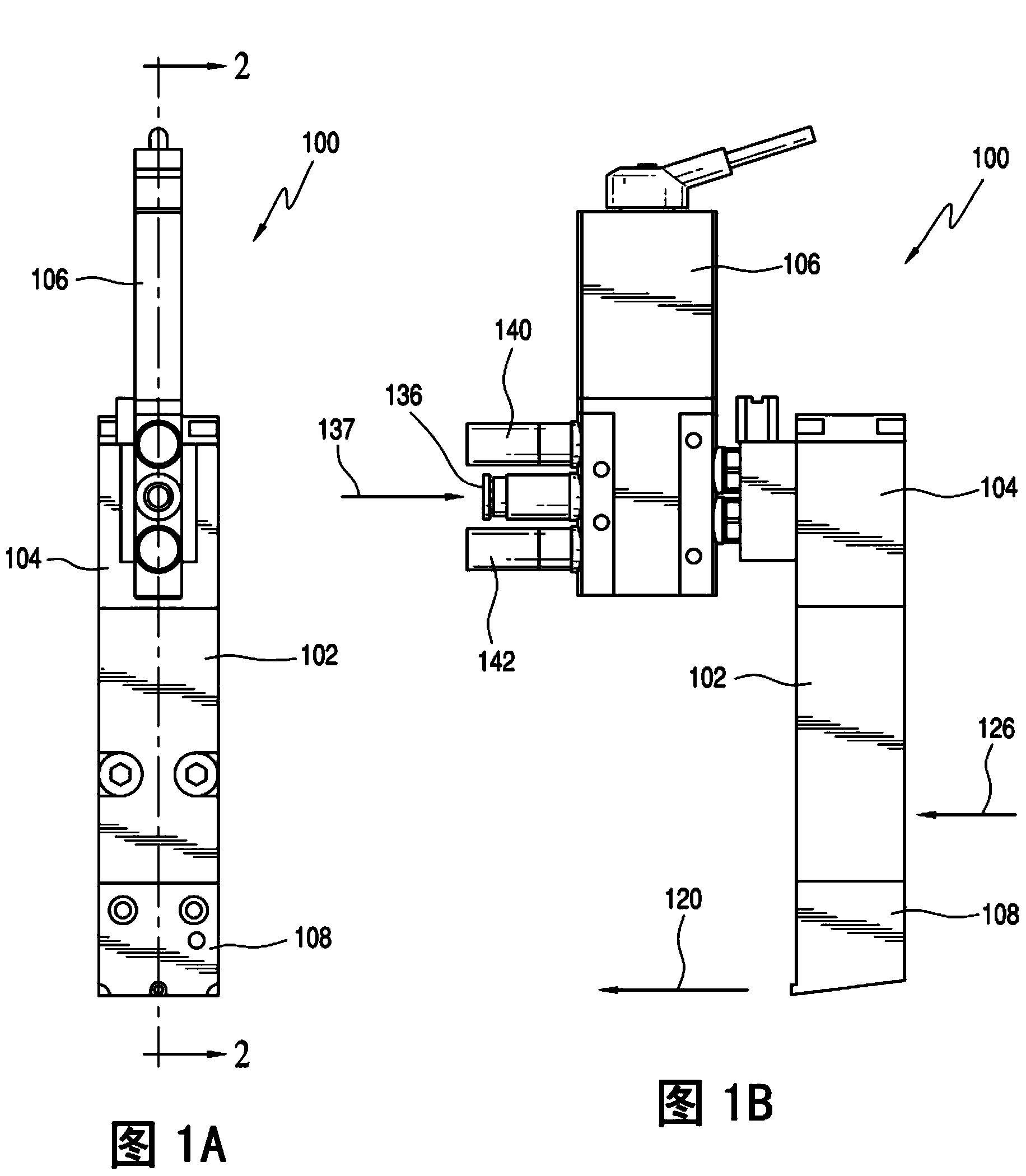

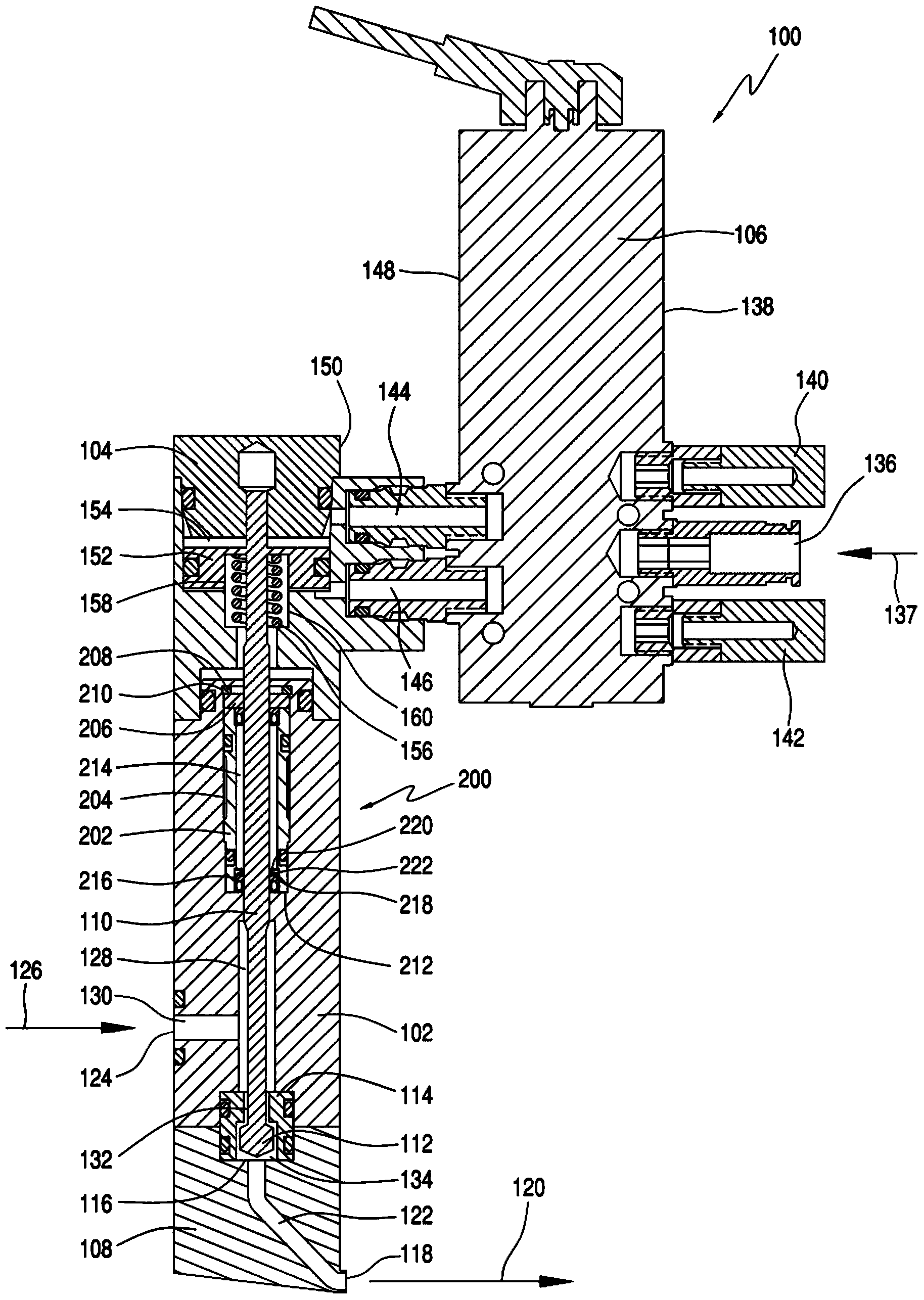

[0013] See attached drawings, especially Figure 1A and Figure 1B , the designation 100 is generally used to disclose and indicate the new and improved hot melt adhesive or other thermoplastic material dispensing valve assembly equipped with the new and improved sealing assembly according to the present invention and the principles of the present invention New and improved hot melt adhesive or other thermoplastic material dispensing valve assemblies constructed from and taught by. More specifically, during operations or cycles in which hot melt adhesives or other thermoplastic materials are applied or dispensed, as substrates or products pass under the dispensing valve assembly 100 along the product process line, the novel valve assembly 100 according to the present invention The improved dispensing valve assembly 100 can be used to dispense hot melt adhesives or other thermoplastic materials onto underlying substrates or products. It can be seen that the dispensing valve as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com