Compositions for low K, low temperature co-fired composite (LTCC) tapes and low shrinkage, multi-layer LTCC structures formed therefrom

A composition and glass composition technology, applied in the direction of circuit substrate materials, thin material processing, inorganic insulators, etc., can solve problems such as non-relief, and achieve the effect of low shrinkage and low overall dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

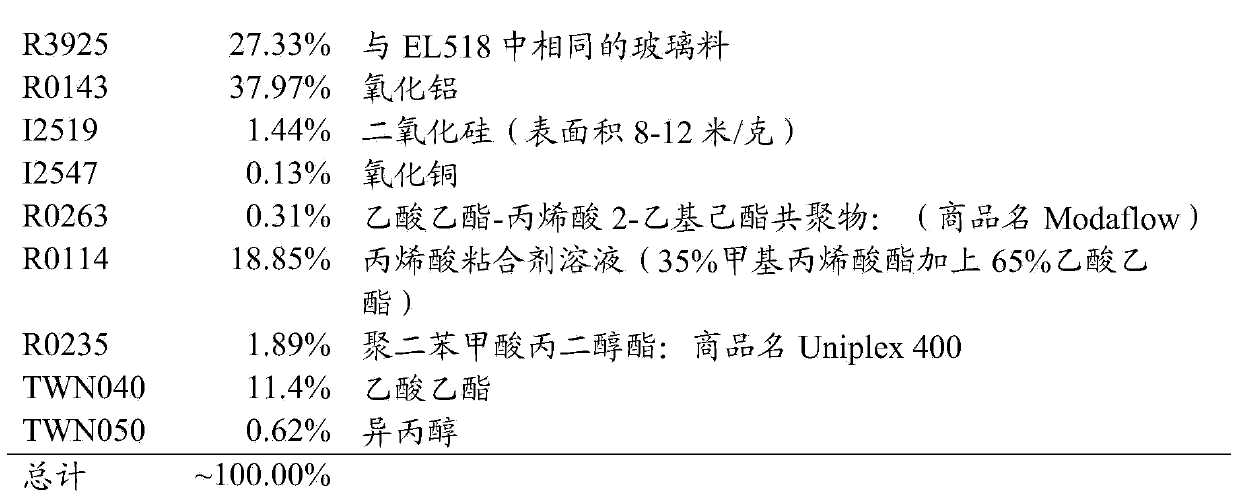

[0088] The tape compositions used in the examples were prepared by ball milling finely divided inorganic powders and binders in volatile solvents or mixtures thereof. For optimization of lamination, ability to form circuit patterns, tape burnout performance, and post-firing microstructure formation, the following volume % paste formulations were found to provide advantages. As with a practical basis, formulations of typical slurry compositions are also shown in weight percent. The glass in the inorganic phase is assumed to have a specific gravity of 3.5 g / cc and the alumina to be 4.0 g / cc, and the organic vehicle is assumed to have a specific gravity of 1.1 g / cc. Therefore, when using glass and oxides other than alumina, the weight % composition changes because the specific gravity may be different from those assumed in this example.

[0089] The volume and weight % of the above slurry composition can be varied depending on the amount of organic solvent and / or solvent blend d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com