Single-layer-structure inverted top-emission OLED (Organic Light Emitting Device)

A single-layer structure, top emission technology, used in organic semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of electron and hole imbalance, unreported, etc., achieve low-efficiency roll-off, and expand the recombination area. , high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The structure of the prepared inverted top-emitting organic electroluminescent device is:

[0032] Device A: Si substrate / Mo(50nm) / Al(5nm) / Cs 2 CO 3 (1nm) / TPBi:10wt%FIrPic:6wt%PO-01(100nm) / MoO 3 (10nm) / Ag(20nm)

[0033] Device B: Si substrate / Mo(50nm) / Al(5nm) / Cs 2 CO 3 (1nm) / TPBi:6wt%PO-01(100nm) / MoO 3 (10nm) / Ag(20nm)

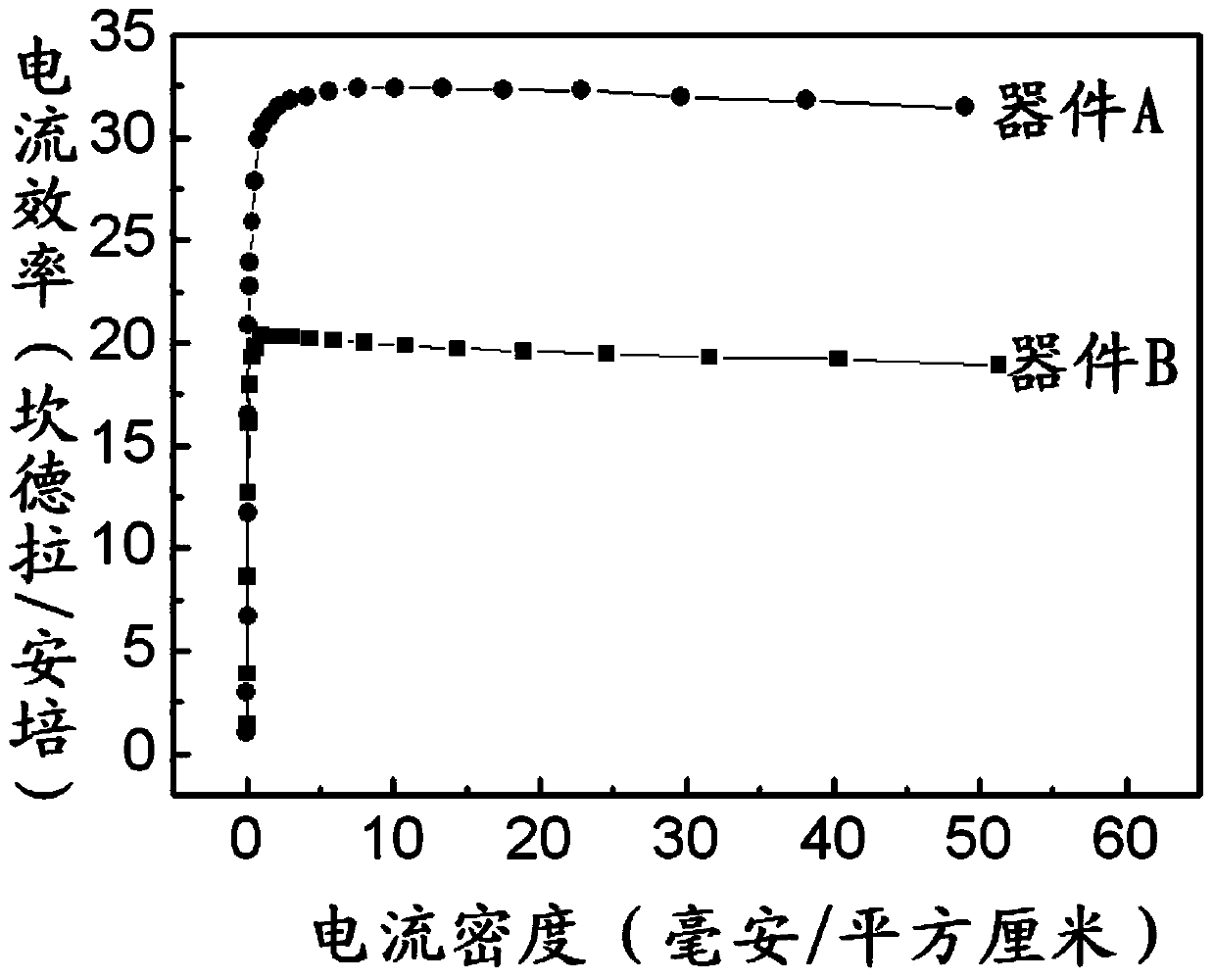

[0034] Wherein device A is a structure designed by the present invention, and device B is a comparative device doped with organic dye 1 only.

[0035] The preparation of the device can be carried out by a multi-source organometallic molecular vapor deposition system, and the detailed process is as follows:

[0036] [1] The substrate material in the experiment is a silicon substrate covered with a silicon dioxide insulating layer. First, the silicon substrate is repeatedly scrubbed with acetone and ethanol cotton balls;

[0037] [2] Put the scrubbed silicon substrate into a clean beaker and use acetone, ethanol, and deionized water to sonicate for...

Embodiment 2

[0041] The structure of the prepared inverted top-emitting organic electroluminescent device C is: silicon substrate / Mo(50nm) / Mg:Ag(5nm) / Cs 2 CO 3 (1nm) / TPBi:10wt%Ir(ppy) 3 :6wt%PO-01(100nm) / MoO 3 (10nm) / Ag(20nm). The volume ratio of Mg:Ag doping is 10:1, and the detailed process of device preparation is as in Example 1.

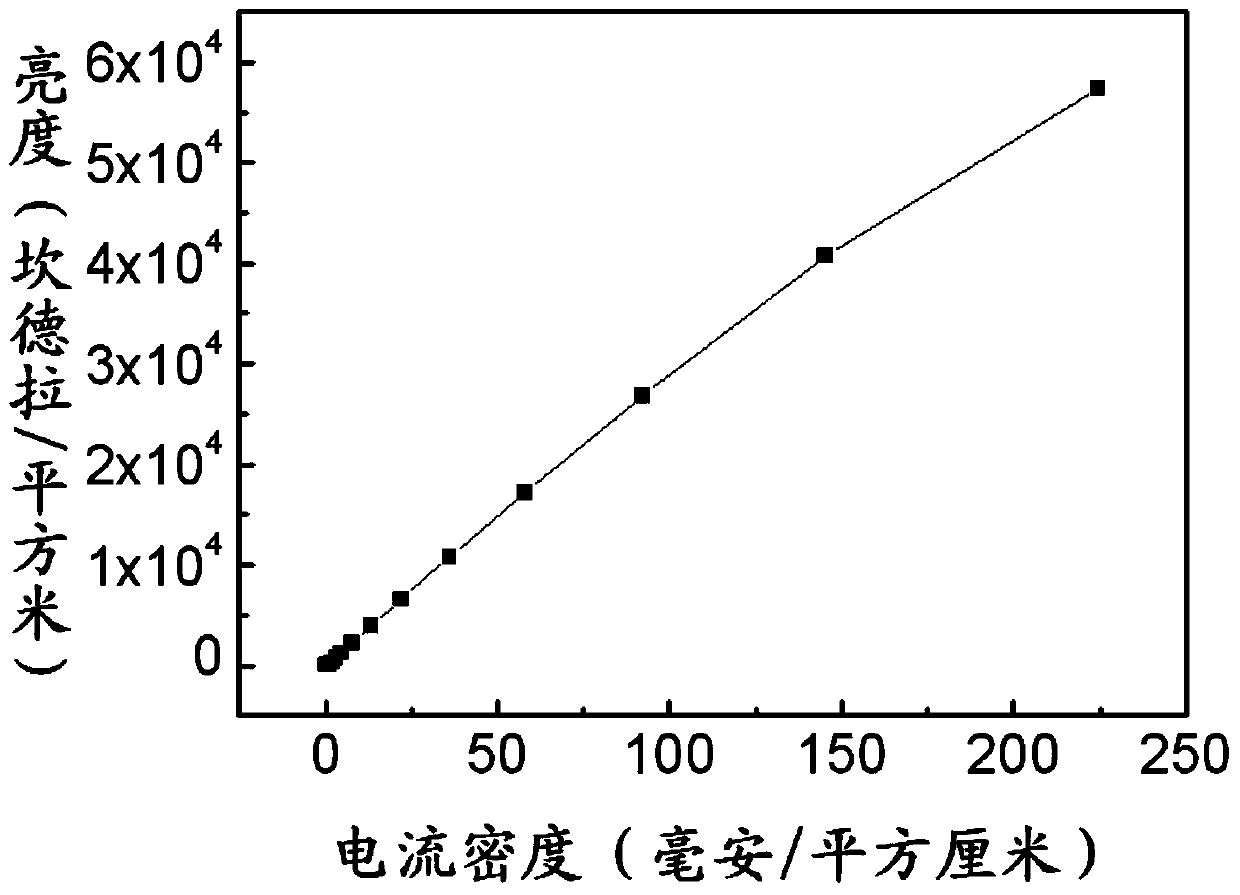

[0042] The brightness-current density of the inverted top-emitting device of the present invention is as follows image 3 shown. As can be seen from the figure, the maximum brightness of the device C designed by the present invention can reach 57384cd / m 2 . The maximum current efficiency of device C can reach 30.1cd / A. The current efficiency-brightness curve of device C is shown as Figure 4 As shown, device C is at 1000cd / m 2 The current efficiency at luminance is 26.3cd / A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com