Low-cost back-contact cell production method suitable for mass production

A technology of back contact battery and production method, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complicated process steps, high equipment investment and high production cost, and achieve the effect of simple process, increased equipment investment, and reduced complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

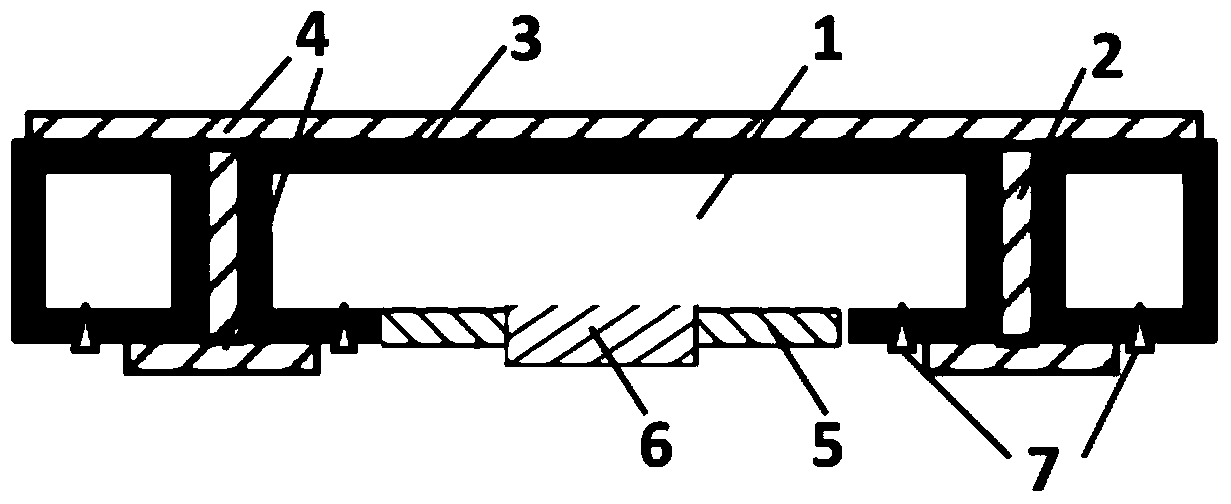

[0032] A method for producing a back contact cell, comprising the following specific steps:

[0033] (1) Use solar-grade P-type monocrystalline or polycrystalline silicon wafers as substrates;

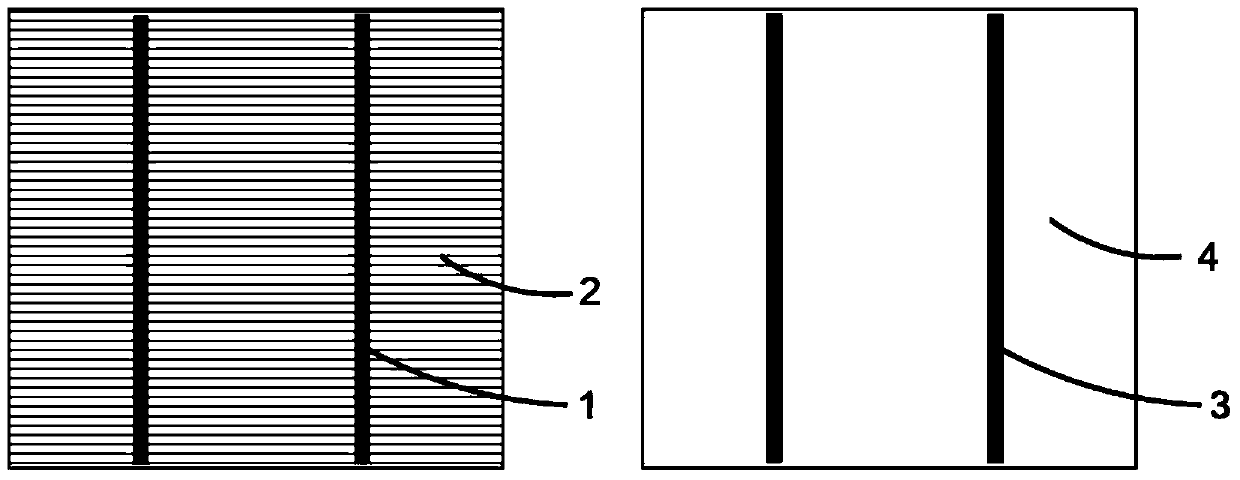

[0034] (2) According to Figure 4 The laser hole is shown, the shape of the hole is circular, and the diameter is 0.1~0.5mm; further, the laser is used to make holes on the crystalline silicon wafer, and the shape of the hole can be round, square or tapered, etc. 1mm, the number and distribution of holes are not limited to Figure 4 shown;

[0035] (3) Cleaning and texturing using conventional chemical cleaning and texturing methods;

[0036] (4) Use POCl3 diffusion source for high-temperature back-to-back single-sided diffusion, and the diffusion resistance is controlled at 40~120Ω / □;

[0037] (5) Prepare a circular paraffin mask with a diameter of 2-8 mm on the back surface of the silicon wafer as the center of the circle, and the preparation method is inkjet printing or screen p...

Embodiment 2

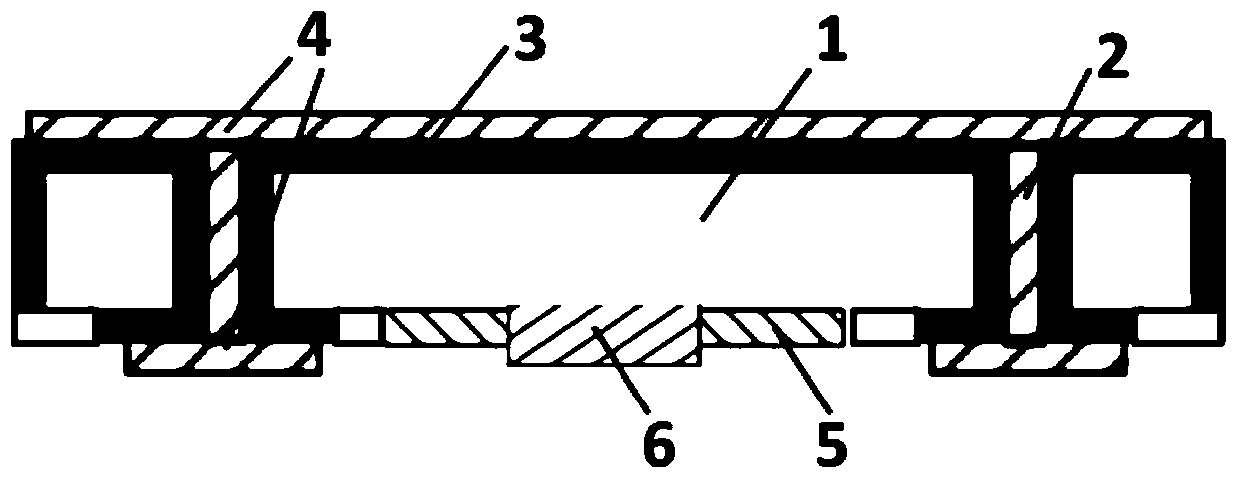

[0044] A method for producing a back contact cell, comprising the following specific steps:

[0045] (1) Use solar-grade P-type monocrystalline or polycrystalline silicon wafers as substrates;

[0046] (2) According to Figure 4 The shown laser opening, the shape of the hole is circular, and the diameter is 0.1~0.5mm;

[0047] (3) Cleaning and texturing using conventional chemical cleaning and texturing methods;

[0048] (4) Use POCl3 diffusion source for high-temperature back-to-back single-sided diffusion, and the diffusion resistance is controlled at 40~120Ω / □;

[0049] (5) Use a chemical solution for chemical post-cleaning to remove the pn junction at the periphery and the back, and remove the phosphosilicate glass formed on the surface of the silicon substrate after diffusion;

[0050] (6) Evaporate SiNx anti-reflection film on the front of the cell, the refractive index is between 1.9 and 2.1, and the film thickness is 70-90nm; on the back of the cell, evaporate the A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com