A component for simulating flexible joints in immersed tunnels

A flexible joint and immersed tunnel technology, which is applied in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc., can solve the problem of large measurement errors, difficult to measure joint reactions, and difficult to use tunnel analysis and design for measurement results. and other problems, to achieve the effect of simple method, easy raw material and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

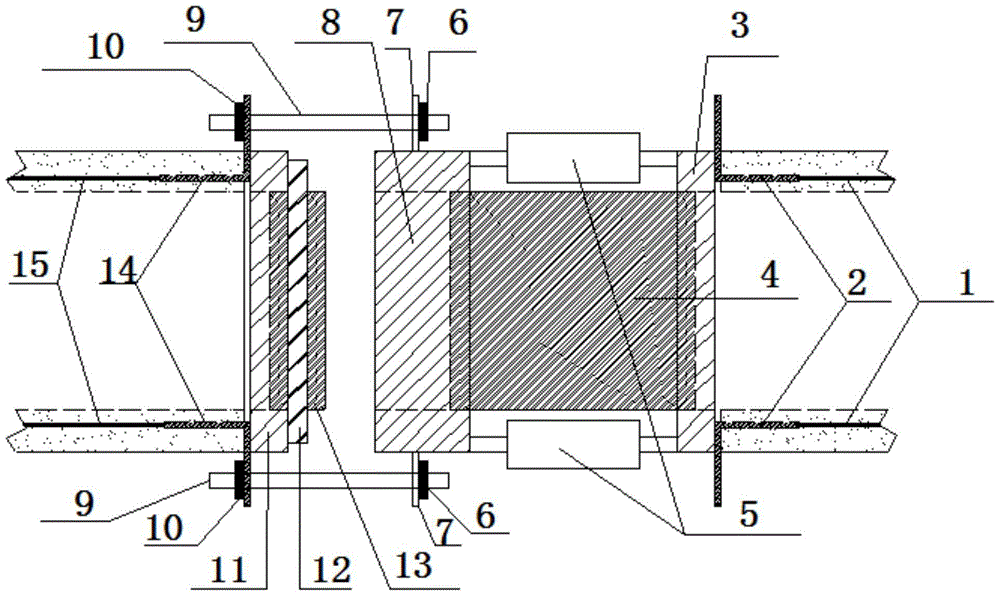

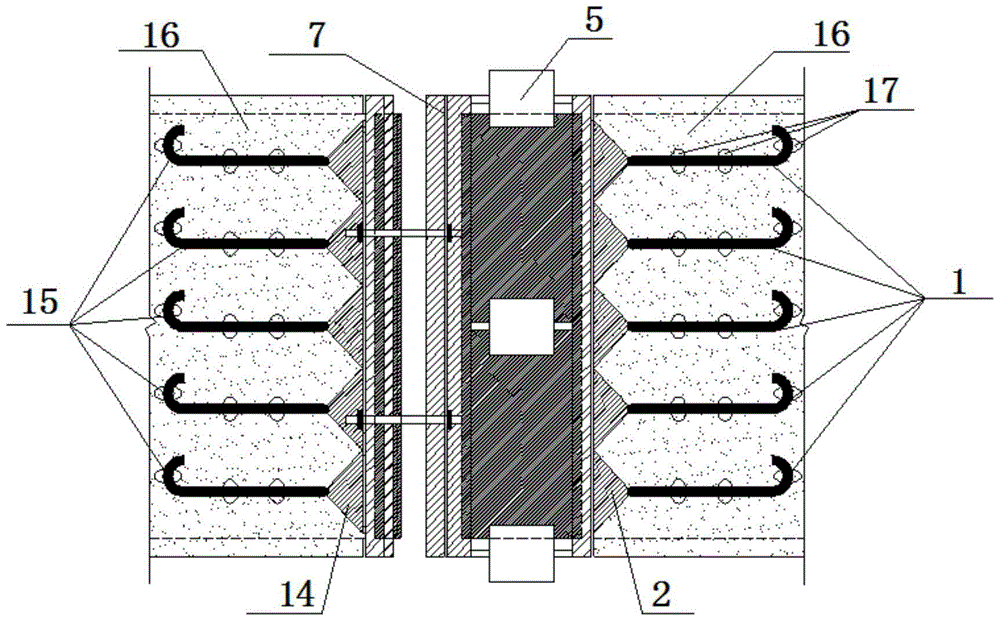

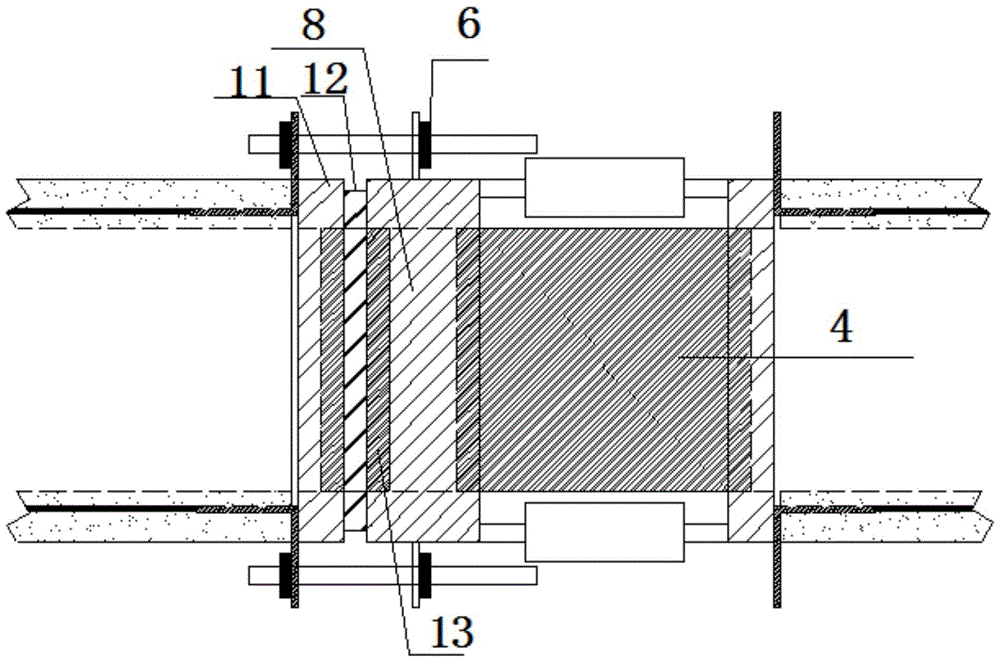

[0025] like Figure 1-9 As shown, the present invention is a component for simulating the flexible joint of an immersed tube tunnel, including steel bar I1, angle steel I2, steel washer I3, steel ring I4, force measuring device 5, loose bolt 6, steel plate 7, and steel ring II8 , High-strength steel wire 9, fixing bolt 10, steel washer Ⅱ11, rubber ring 12, steel ring Ⅲ13, angle steel Ⅱ14, steel bar Ⅱ15. The extremities of steel bar I1 and angle steel I2 embedded in concrete structure 16 are welded, steel washer I3 is welded to the extremities of upper and lower angle steel I2 not embedded in concrete structure 16, and one end of steel ring I4 is welded to the end of steel washer I3 inner wall. The extremities of steel bar II15 and angle steel II14 embedded in the concrete structure 16 are welded, the steel washer II11 is welded to the extremities of the upper and lower angle steel II14 not embedded in the concrete structure 16, and one end of the steel ring III13 is welded to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com