Waste heat energy saving automatic humidification and drying line

An automatic and wet drying technology, applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems of low work efficiency, insufficient energy utilization, long production time, etc., to improve product quality and work efficiency Efficiency, high water resource utilization rate, comprehensive and uniform humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

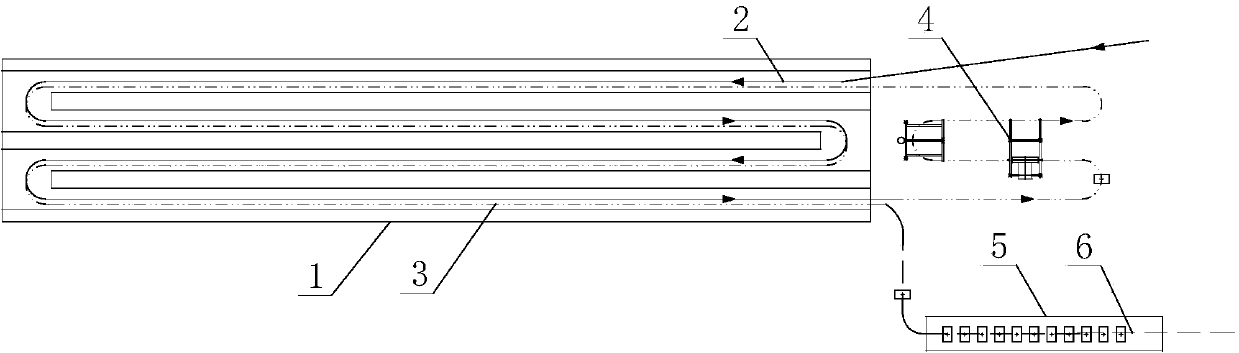

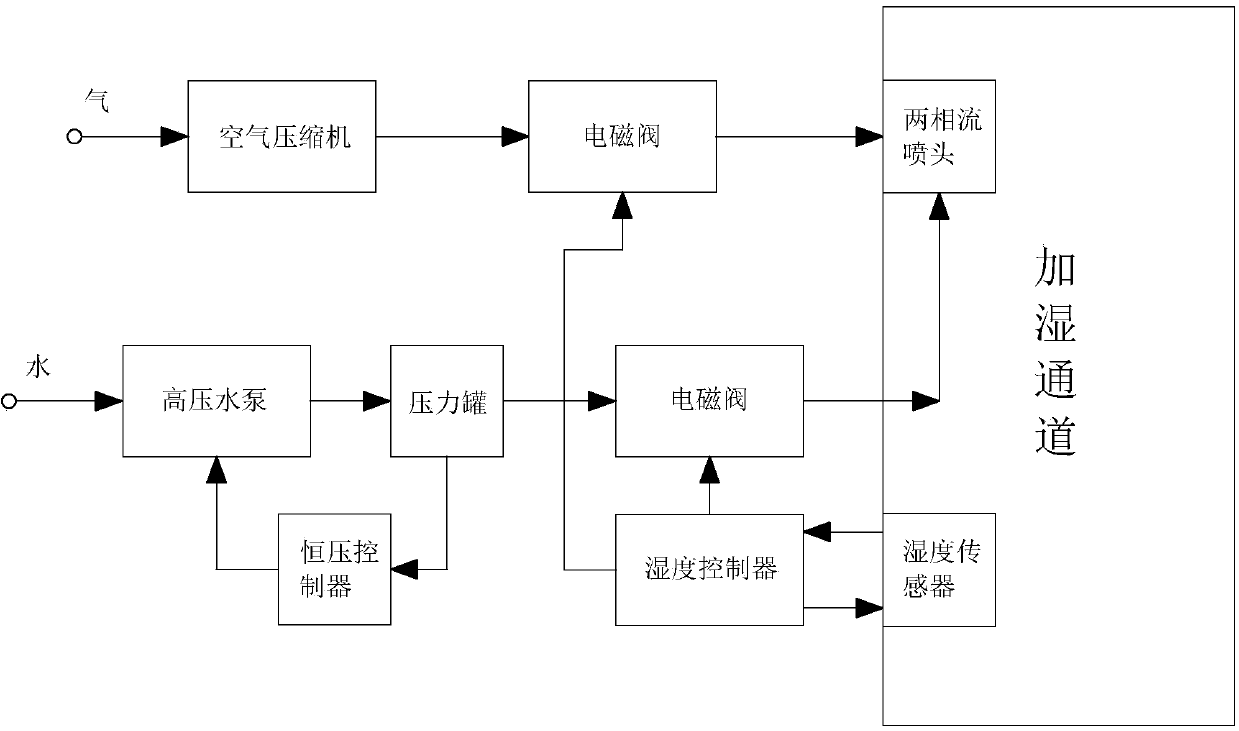

[0019] Embodiment 1: as Figures 1 to 2 As shown, a waste heat energy-saving automatic humidification and drying line, the humidification and drying line includes a drying zone 1 and an automatic humidification zone set at the outlet of the drying zone. The drying zone is divided into upper and lower layers, and the upper drying zone There is a product conveying line in the lower drying area, and the product conveying line 2 in the upper drying area is connected with the product conveying line 3 in the lower drying area. There is a drying channel in the lower drying area, and the lower drying area The product conveying line 3 in the dry zone is located in the drying channel, and multiple heat exchangers are arranged in the drying channel, and the heat exchangers are located above the product conveying line 3 .

[0020] The product conveying line 2 in the upper drying area and the product conveying line 3 in the lower drying area are connected by a driving device 4, which is us...

Embodiment 2

[0028] Example 2: The difference from Example 1 is that in Example 2, there are 180 gas-liquid two-phase flow nozzles, and every 10 gas-liquid two-phase flow nozzles form a group, which are arranged in a staggered way in the humidification channel for product delivery both sides of the line.

[0029] Working principle is the same as embodiment 1.

Embodiment 3

[0030] Example 3: The difference from Example 1 is that in Example 3, there are 220 gas-liquid two-phase flow nozzles, and every 10 gas-liquid two-phase flow nozzles form a group, which are arranged in a staggered way in the humidification channel for product delivery both sides of the line.

[0031] Working principle is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com