Internal vacuum valve

A vacuum valve, built-in technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of cumbersome procedures for operators, product bumps and damage, complex manufacturing processes, etc., to achieve beautiful appearance, prolong service life, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

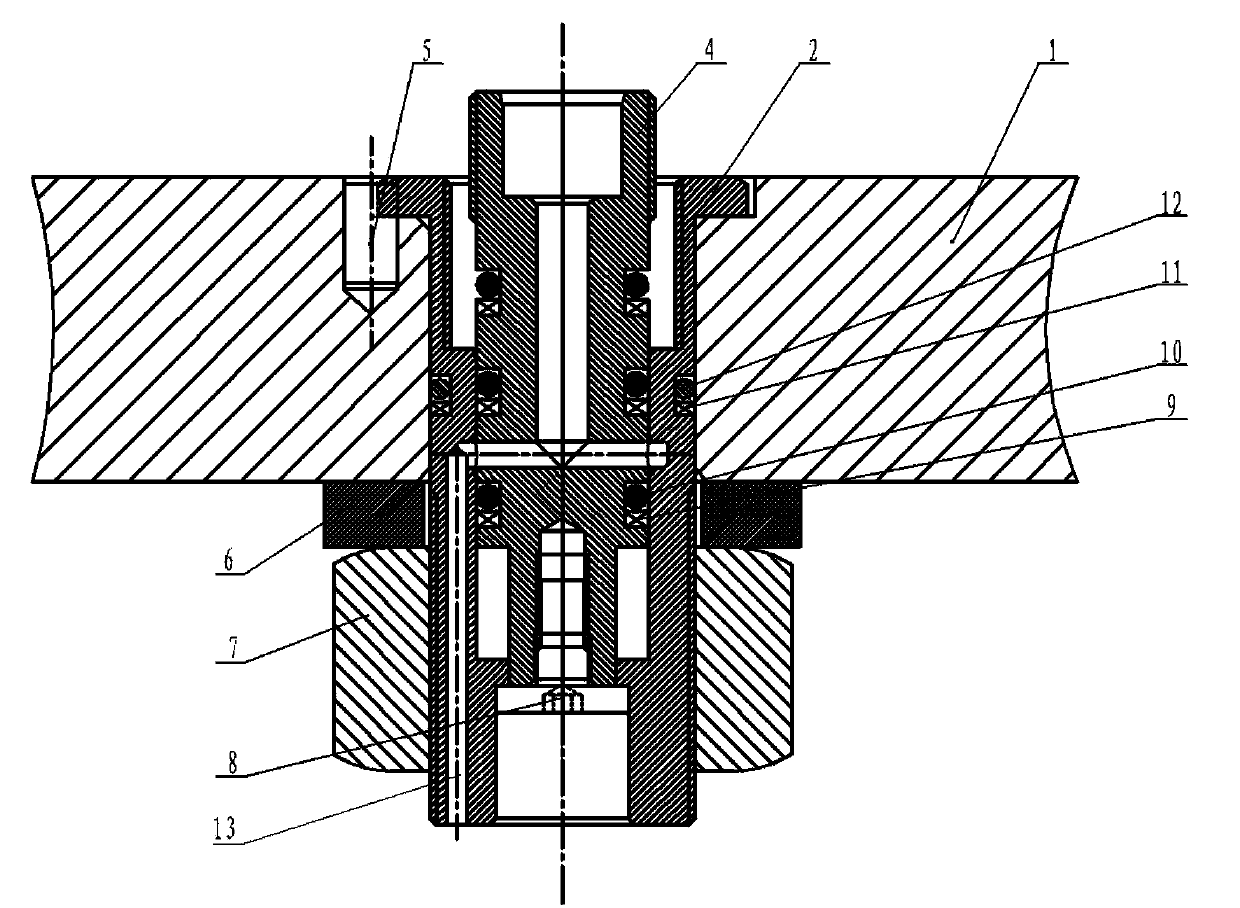

[0013] A built-in vacuum valve, such as figure 1 , figure 2 As shown, it includes a valve sleeve 2, a valve cover 3, a valve core 4, an orientation pin 5, a limit screw 8, a first retaining ring 9, a first sealing ring 10, a second retaining ring 11, and a second sealing ring 12. The valve sleeve 2 is fixed on the housing 1 through the gasket 6 and the nut 7, the valve sleeve 2 is provided with a valve core 4, the valve cover 3 is arranged on the valve core 4, and the outer wall of the valve core 4 is provided with three annular recesses. groove, each annular groove is provided with a first retaining ring 9 and a first sealing ring 10, an annular groove is respectively provided on the outer wall and the inner wall of the valve sleeve 2, and the second retaining ring 11 and the second sealing ring 12 are provided In the annular groove on the outer wall of the valve sleeve 2, a through hole 13 communicating with the annular groove on the inner wall of the valve sleeve 2 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com