Semi-finished product of O-shaped ring with inner diameter smaller than 0.5 mm, forming die and trimming method thereof

A semi-finished product, inner diameter technology, used in the field of rubber product trimming, can solve the problems of cracks on the surface of the O-ring, difficult to operate, unable to be cleaned, etc., to achieve high trimming efficiency, easy to remove, and improve the effect of trimming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

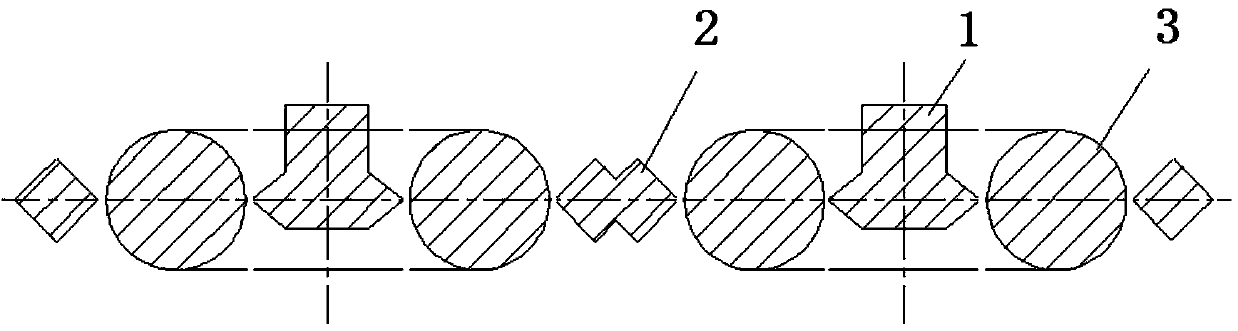

[0042] combine figure 1 , the semi-finished product of the O-ring in this embodiment has an inner diameter of 0.4 mm and a wire diameter of 0.8 mm. Its structure includes an O-ring 3, a boss 1 and a diamond-shaped cutting edge 2, and the inner ring cutting edge of the O-ring 3 is set There is a boss 1, and the edge of the outer ring of the O-ring 3 is provided with a diamond-shaped cutting edge 2. The boss 1 is rectangular, and the boss 1 is 0.3mm higher than the top of the O-ring 3 . The left end point and the right end point of the bottom of the boss 1 are respectively 0.03 mm away from the inner edge of the O-ring 3 .

[0043] The diamond-shaped cutting edges 2 of the outer rings of adjacent O-rings 3 overlap each other, and the overlapping width is 1 / 2 of the horizontal width of the diamond-shaped cutting edges 2, so that the semi-finished products are connected to form a network structure. One end of the diamond-shaped cutting edge 2 close to the O-ring 3 is 0.03mm away...

Embodiment 2

[0056] Such as figure 1 , The O-ring semi-finished product of this embodiment has an inner diameter of 0.48 mm and a wire diameter of 1 mm. Its structure is basically the same as in Embodiment 1, except that the boss 1 is 0.5 mm higher than the top of the O-ring 3 . The left end point and the right end point of the bottom of the boss 1 are respectively 0.05 mm away from the inner edge of the O-ring 3 . One end of the diamond-shaped cutting edge 2 close to the O-ring 3 is 0.05mm away from the outer edge of the O-ring 3 .

[0057] The trimming method of O-ring semi-finished product of the present invention, its steps are:

[0058] (1) Feeding: Add 12,000 untrimmed O-rings (volume about 3.2L) to the cylinder 6 of the 10L pulsator trimmer, and the volume of the O-ring is 2 / of the effective volume of the cylinder 6 5;

[0059] (2) Spray lubricant: Spray 1.5mL of water on the surface of the O-ring in the cylinder as a lubricant, and cover the upper cover 7, such as image 3 ; ...

Embodiment 3

[0068] The semi-finished product of the O-ring 3 of this embodiment, the inner diameter of the O-ring 3 is 0.44mm, the wire diameter is 0.9mm, its structure is basically the same as that of Embodiment 1, the difference is that the boss 1 is higher than the O-ring 3 Top 0.4mm. The left end point and the right end point of the bottom of the boss 1 are respectively 0.04 mm away from the inner edge of the O-ring 3 . One end of the diamond-shaped cutting edge 2 close to the O-ring 3 is 0.04mm away from the outer edge of the O-ring 3 .

[0069] The semi-finished trimming method of O-ring 3 of the present invention, its steps are:

[0070] (1) Feeding: Add 10,000 pieces of untrimmed O-rings (volume about 2.7L) to the cylinder 6 of the 10L pulsator-type trimming machine, and the volume of the semi-finished O-ring 3 is the effective volume of the cylinder 6 1 / 3;

[0071] (2) Spray lubricant: Spray 1mL of water on the surface of the O-ring 3 inside the cylinder 6 as a lubricant, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com