A Rotary Vacuum Diffusion Pump

A vacuum diffusion and rotary technology, which is applied in the direction of diffusion pumps, non-volume pumps, pumps, etc., can solve the problems that the ultimate vacuum degree cannot be further improved, the pumping speed is restricted, and it is difficult to increase it, so as to increase the length, Improve the pumping speed and speed up the effect of collision movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

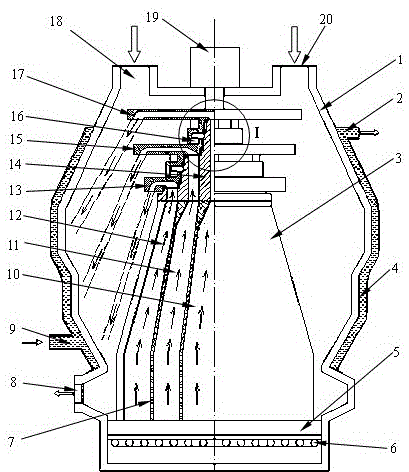

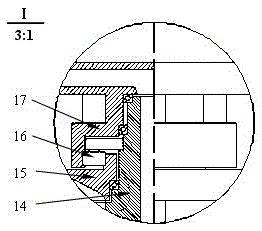

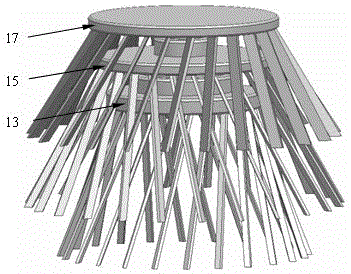

[0022] A vacuum diffusion pump of the present invention is such as figure 1 As shown, the basic structure includes: a pump body 1, an air inlet 18 and an air outlet 8, a filter screen 20, a cooling water tank 4, a heating device 6 and a fractionation device 5, an evaporation oil chamber 3 and a multi-stage rotary nozzle. The characteristic structure is: The pump body 1 is in the shape of a spindle; the evaporation oil chamber 3 is in the shape of a cone, on which there are connecting pipes 14 connected to the multi-stage nozzles; the multi-stage rotating nozzles are connected and driven by a planetary gear mechanism and driven by a motor 19; The nozzle is elliptical, and the ratio of the long axis to the short axis of the elliptical nozzle is (10-20): 1.

[0023] The specific implementation is as follows:

[0024] (1) Pump body 1: in the shape of a spindle; two air inlets 18 are symmetrically distributed at the top, and one air outlet 8 is at the bottom; there is a heating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com