Design and manufacturing of ultra-large rectangular or oblong-shaped LNG storage tank

A rectangular, super-large technology, used in building types, large-capacity bulk material storages, buildings, etc., can solve problems such as difficulty in manufacturing and stress, high energy consumption and difficulty in refrigeration systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

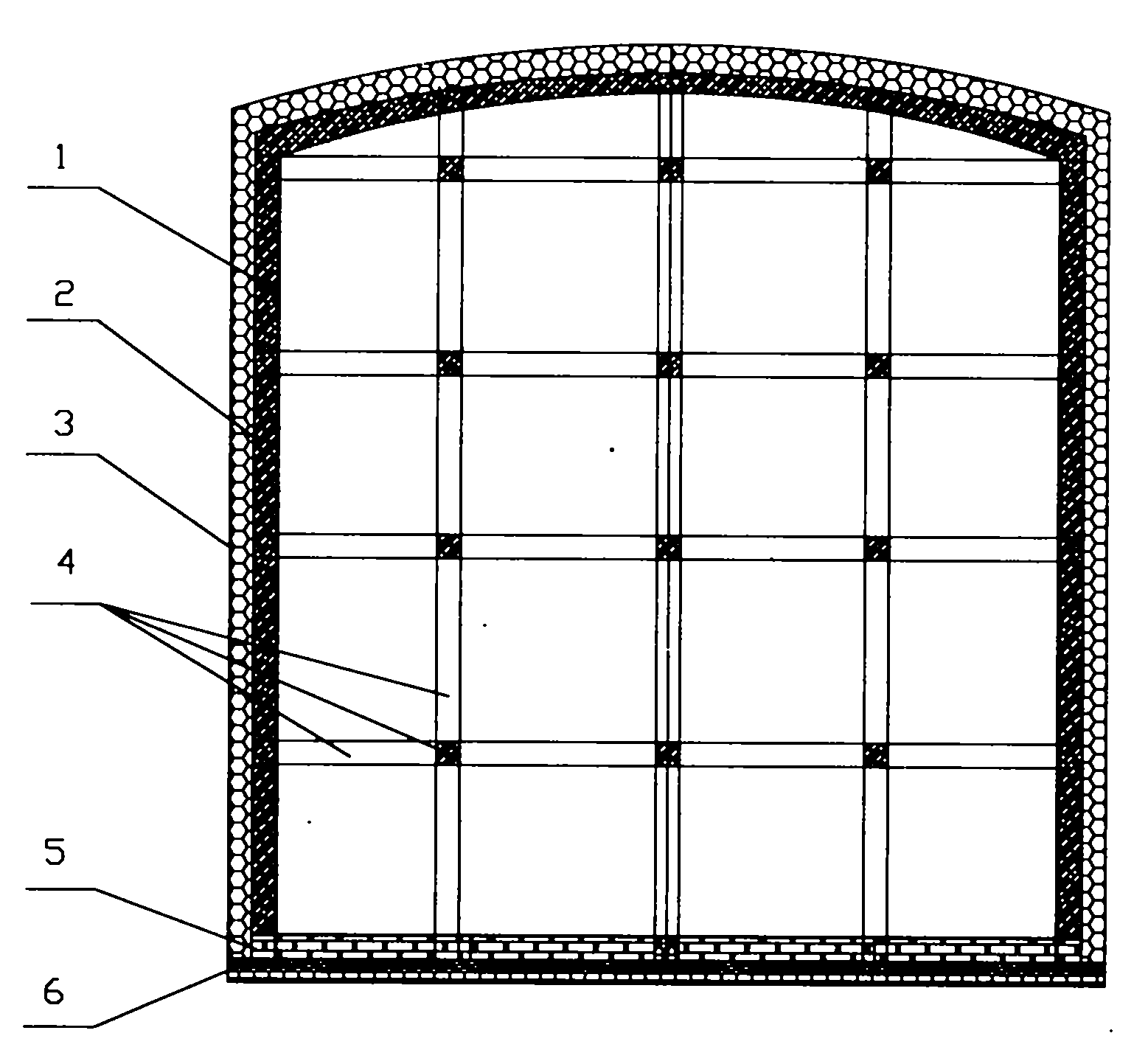

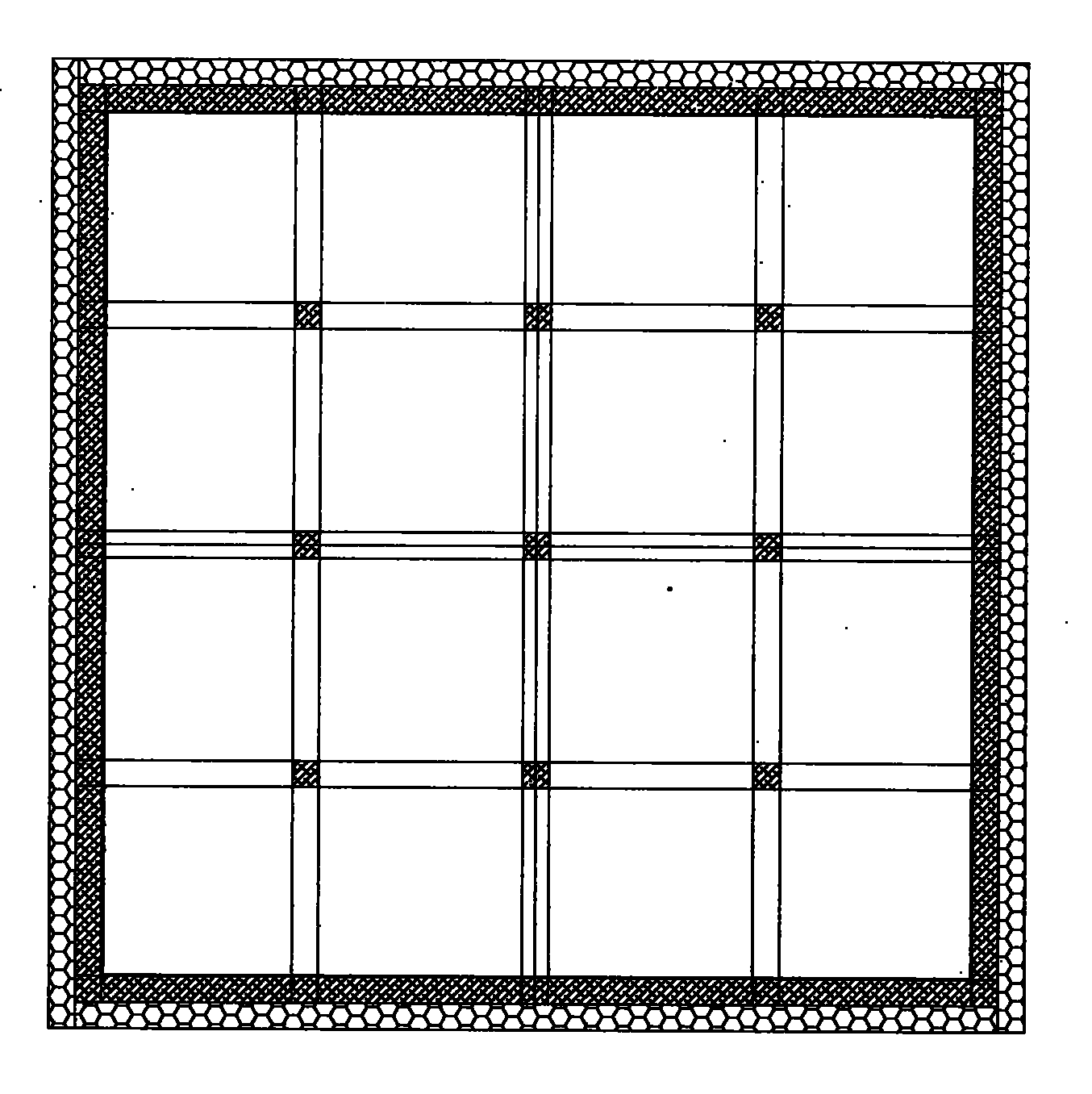

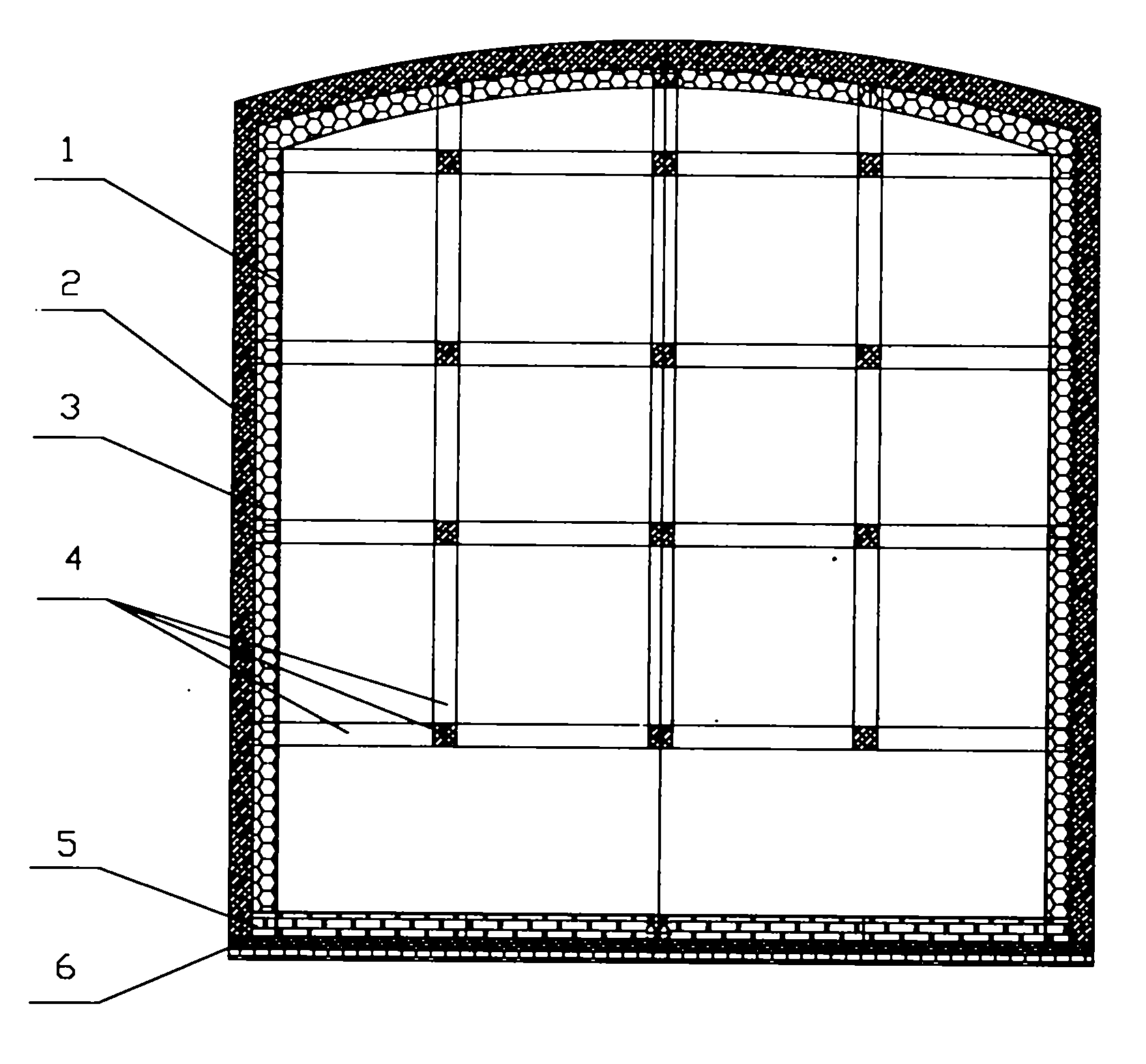

[0012] exist figure 1 Among them, the material layer (1) includes a layer on the bottom surface, which is an inner coating or an inner coating layer, the inner coating is leak-proof, anti-freeze cracking, and anti-corrosion paint, and the inner coating layer is low-temperature nickel steel, stainless steel, ceramics or low-temperature resistant The plastic board can also be composed of an inner coating and an inner layer. This stress-bearing layer is a rectangular or rectangular LNG tank of prestressed reinforced concrete in the inner layer, and it is best to adopt small pieces of ceramics as the material layer (1). The prestressed reinforced concrete layer (2) of the force-bearing layer can include a bottom surface and vertical four walls that are all straight plates, and the overall fabrication and processing are very easy. The prestressed reinforced concrete beam frame (4) can be manufactured together with the prestressed reinforced concrete layer (2). The prestressed rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com