Method for regulating printing technical parameters of printing machine and other parameters related to printing process

A technology for adjusting parameters and printing machines. It is used in general parts of printing machinery, printing machines, printing and other directions, and can solve problems such as deviation in machine adjustment, difficulty in measurement, and inability to measure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

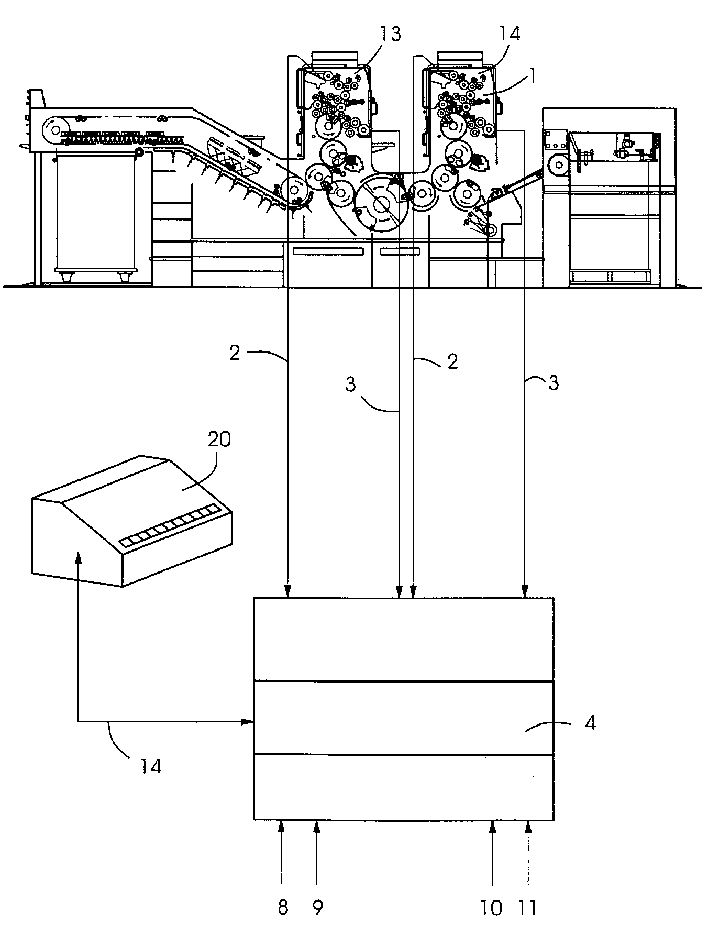

[0029] The printing press 1 is equipped with a series of connection structures 2 , 3 to a central or several sub-central control devices 4 . Lines 2, 3 are shown to represent other connection configurations. Via line 2 , information about the color adjustment of printing unit 13 or 14 is detected by sensors and communicated to control unit 4 . For example, this information can indicate the position of individual ink zones or ink knives along the ink fountain roller, which are adjusted according to the ink distribution. The information transmitted via the connecting structure 2 can also relate to the ink level in the ink fountain or other important data for color adjustment. For example, it is stated that the humidity information input to the corresponding roller during offset printing can enter the control device 4 via the connection structure 3 . What is important is that, on behalf of all other data, data describing the adjustment of individual values in the printing pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com